Patents

Literature

39results about How to "To achieve the purpose of correcting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Grouting reinforcement and rectification method suitable for high-rise building structure

ActiveCN107435346ASolve for uniformityTo achieve reinforcementFoundation engineeringSupporting systemStructure of the Earth

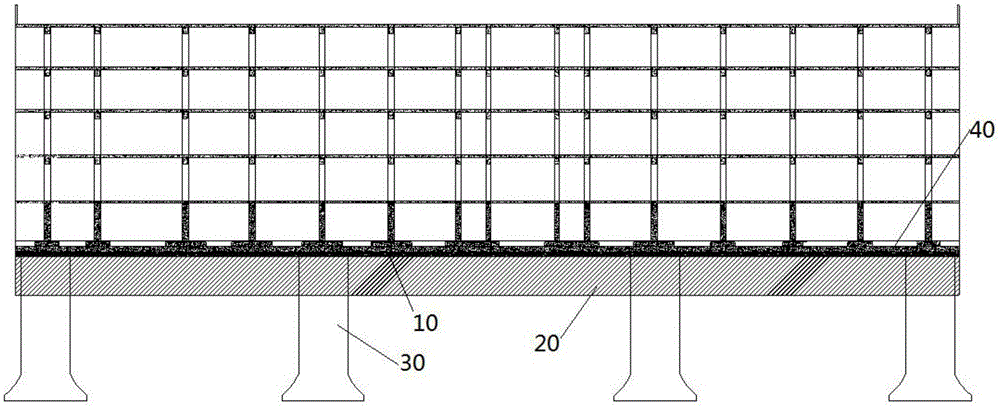

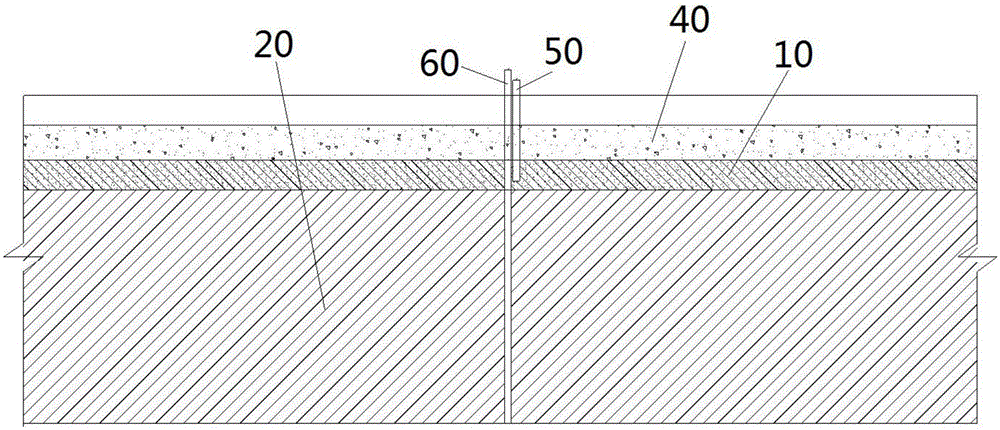

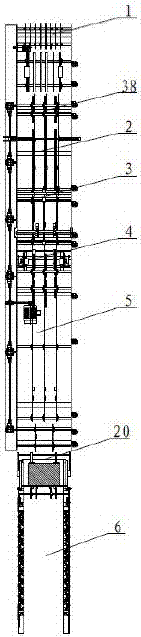

The invention provides a grouting reinforcement and rectification method suitable for a high-rise building structure. The method comprises the steps from S10 to S30, wherein in the step S10, grouting filling reinforcement is conducted on an original cushion layer under an original concrete valve plate, and the original cushion layer and grout are solidified to form a cushion layer reinforcement and strengthening layer; in the step S20, after the cushion layer reinforcement and strengthening layer is formed, grouting filling reinforcement is carried out on an original foundation under the original cushion layer, and the original foundation and grout are solidified to form a foundation reinforcement platform; in the step S30, after the foundation reinforcement platform is formed, a plurality of pile foundation grouting holes are vertically formed in the lower surface of the foundation reinforcement platform at intervals, grout is injected into the pile foundation grouting holes to form an under-column pile foundation. The cushion layer reinforcement layer, the foundation reinforcement platform and the under column pile foundation form a three-dimensional supporting system in the mode that the layers are reinforced layer by layer from top to bottom; the purpose of building foundation reinforcement and lifting rectification integration is achieved, and the problems that a building is not uniform in settlement and a rectification foundation is lifted are successfully solved.

Owner:BEIJING HENGXIANG HONGYE FOUND REINFORCEMENT TECH CO LTD

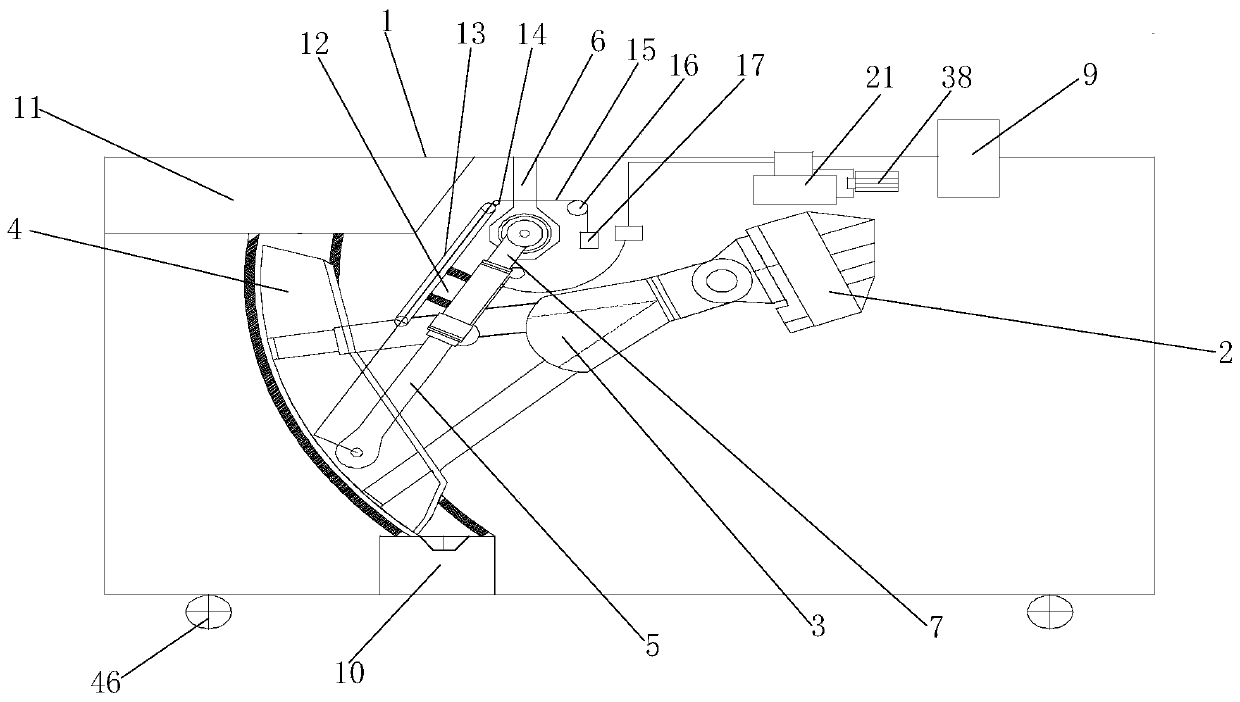

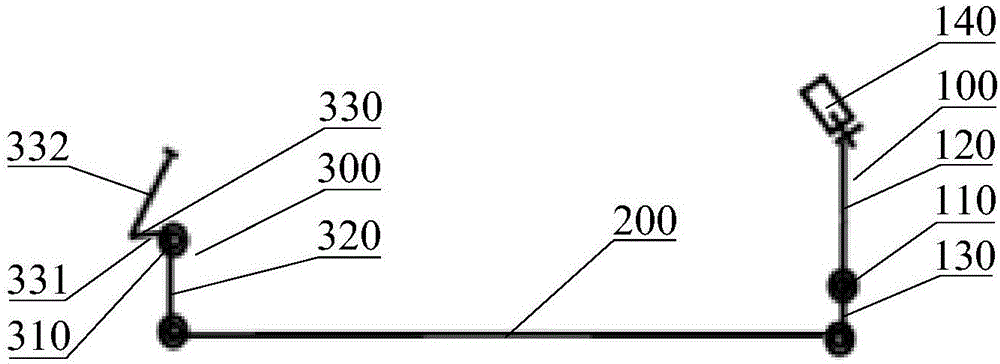

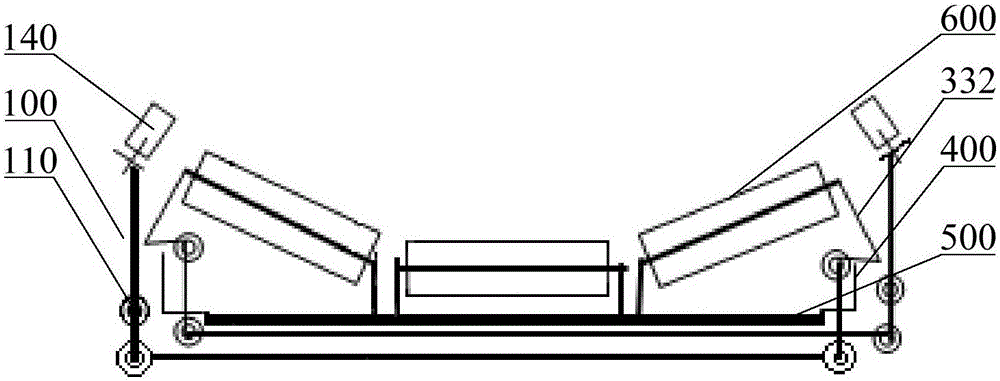

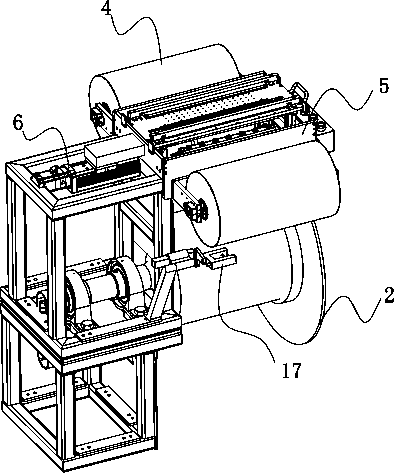

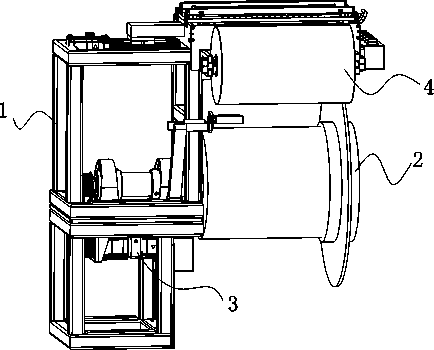

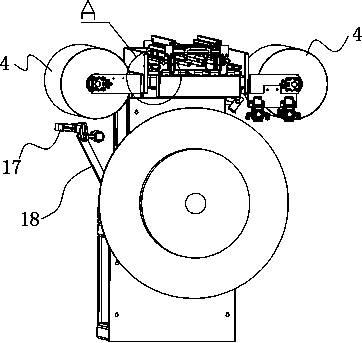

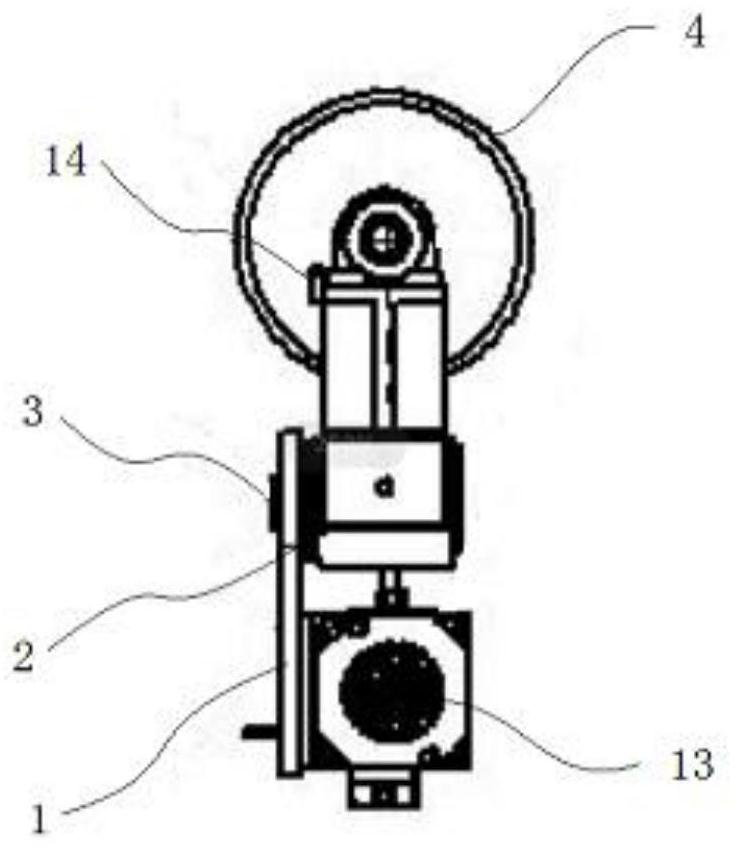

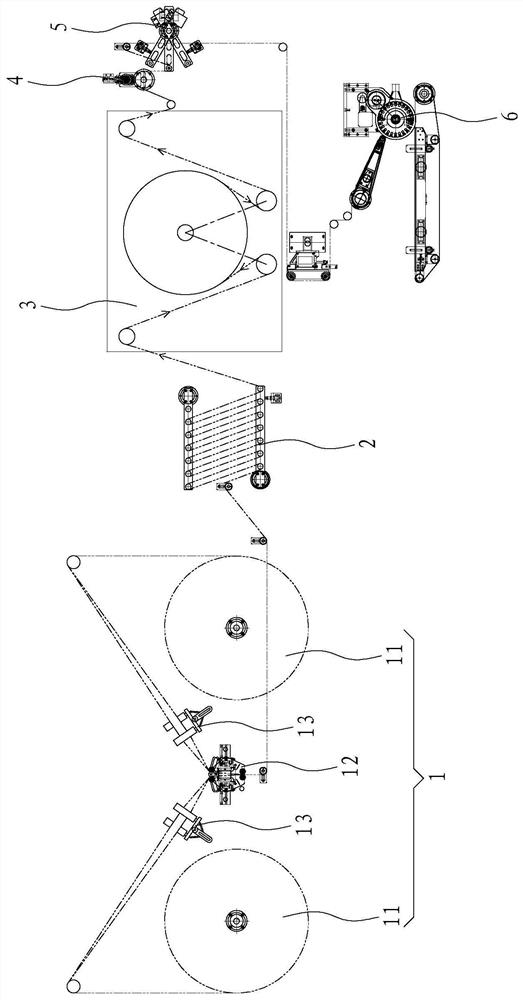

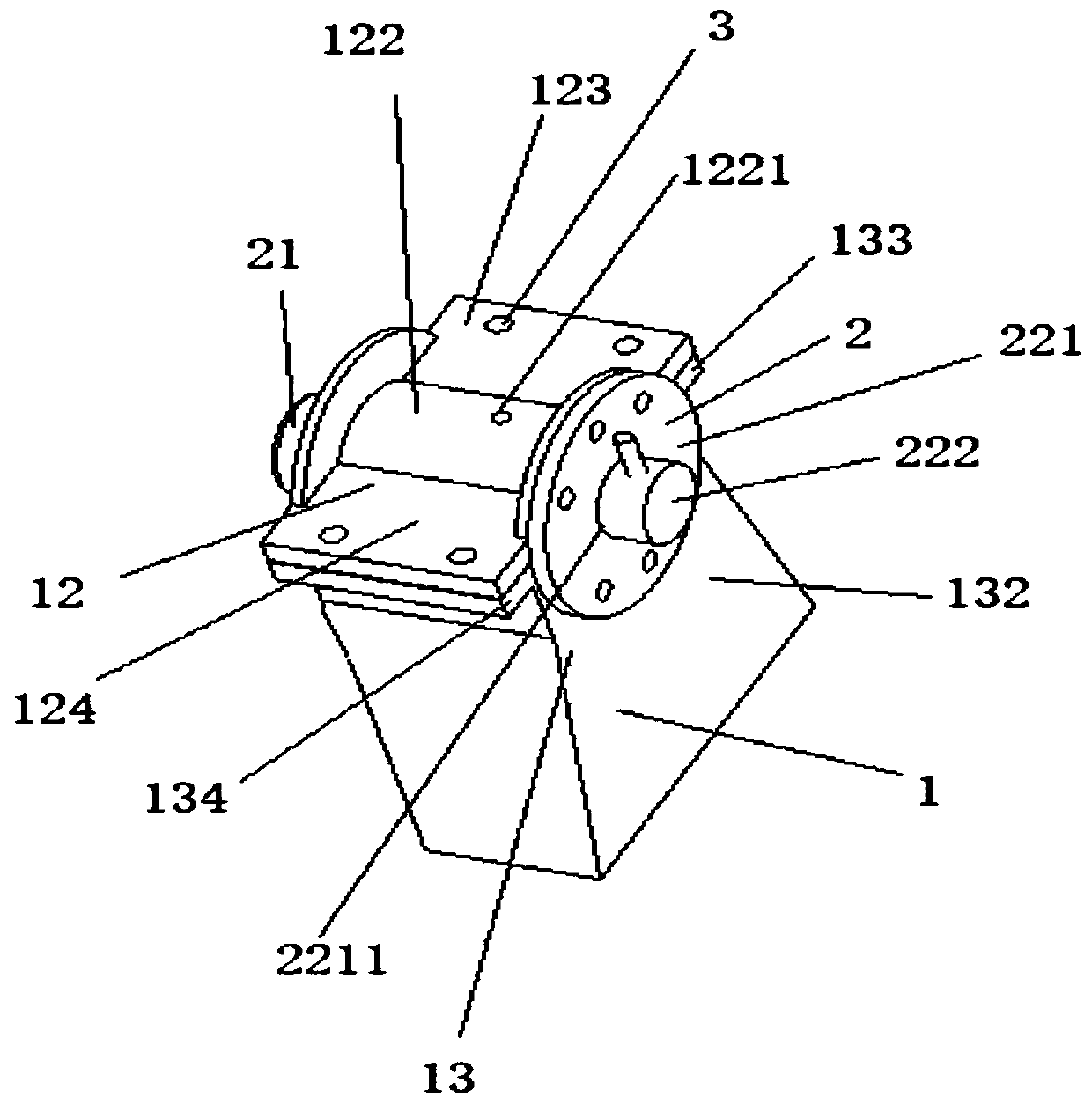

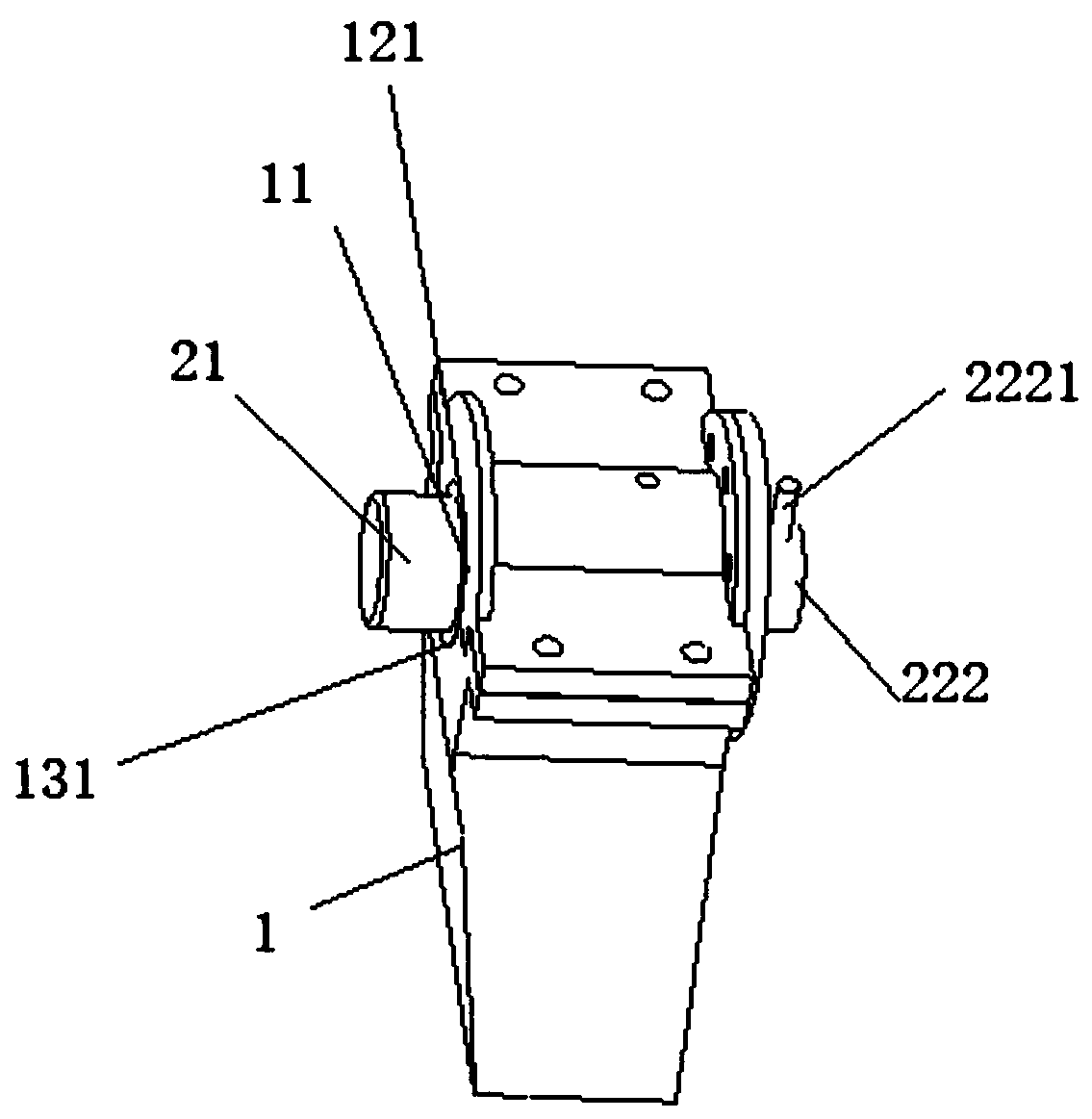

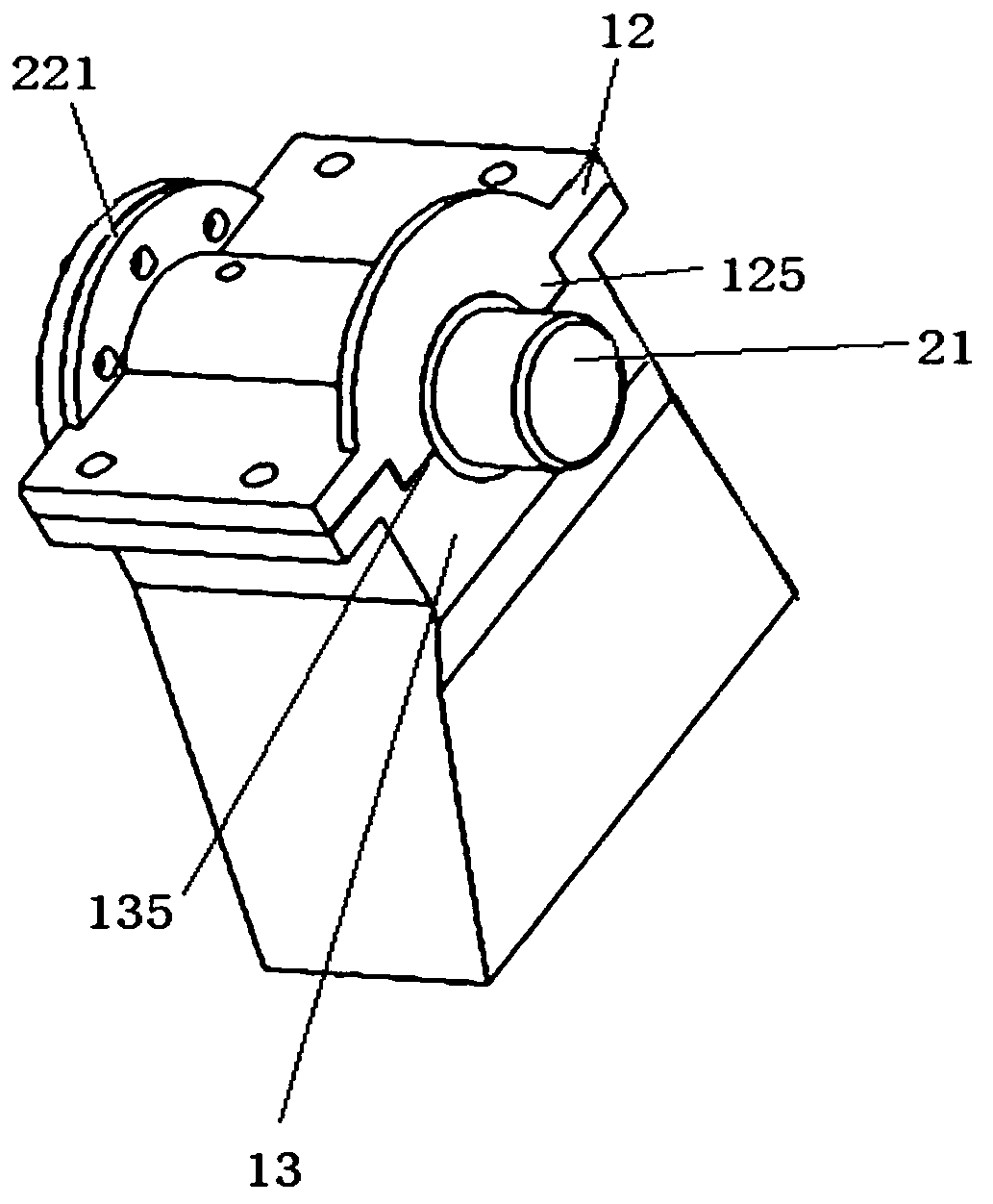

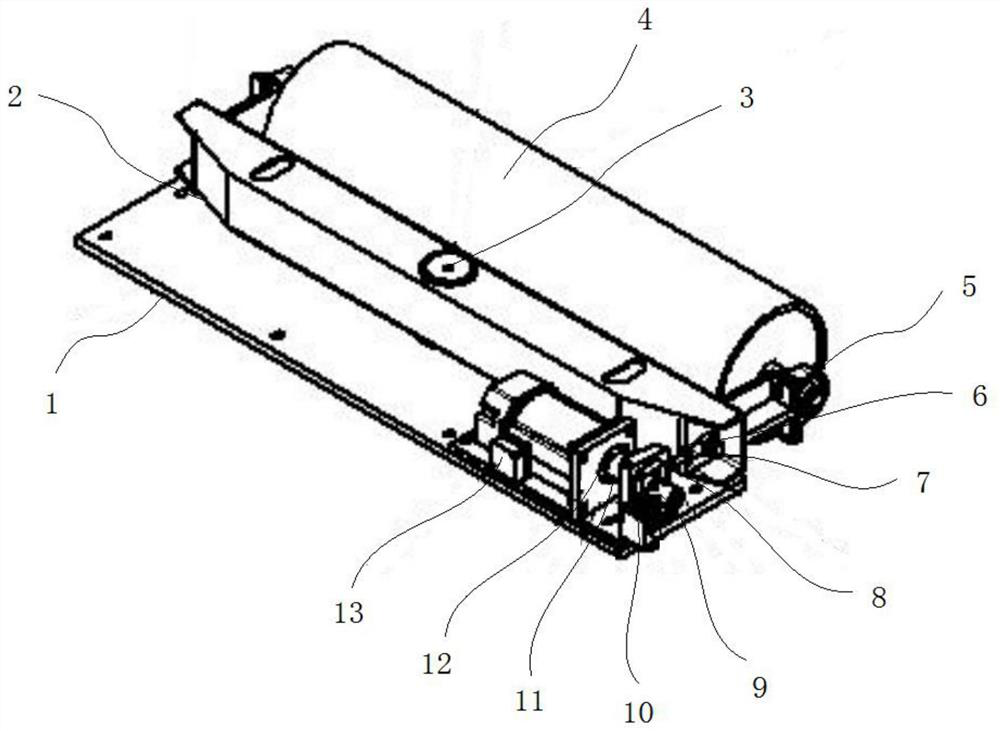

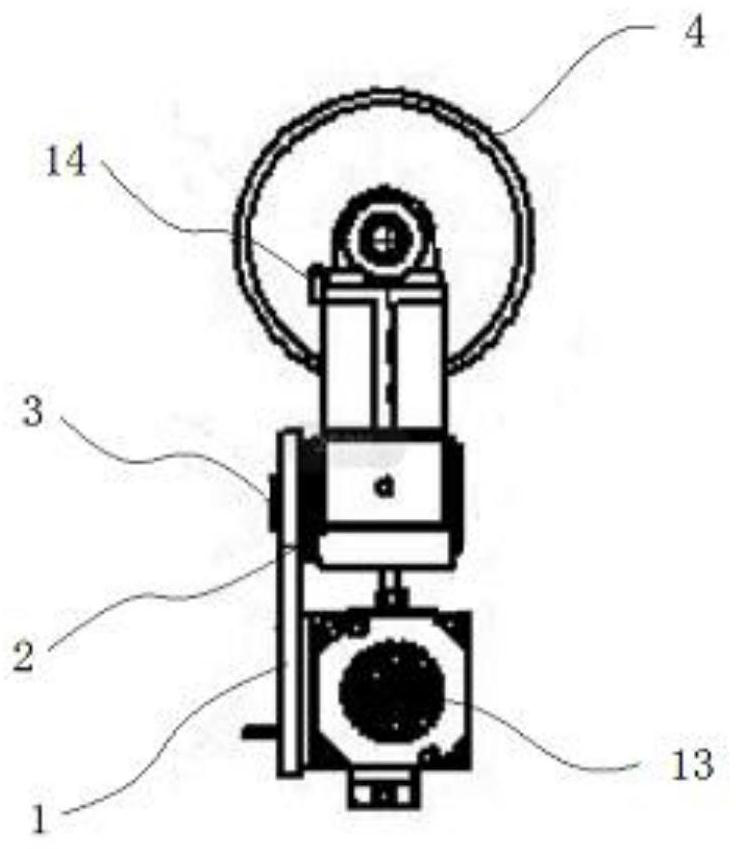

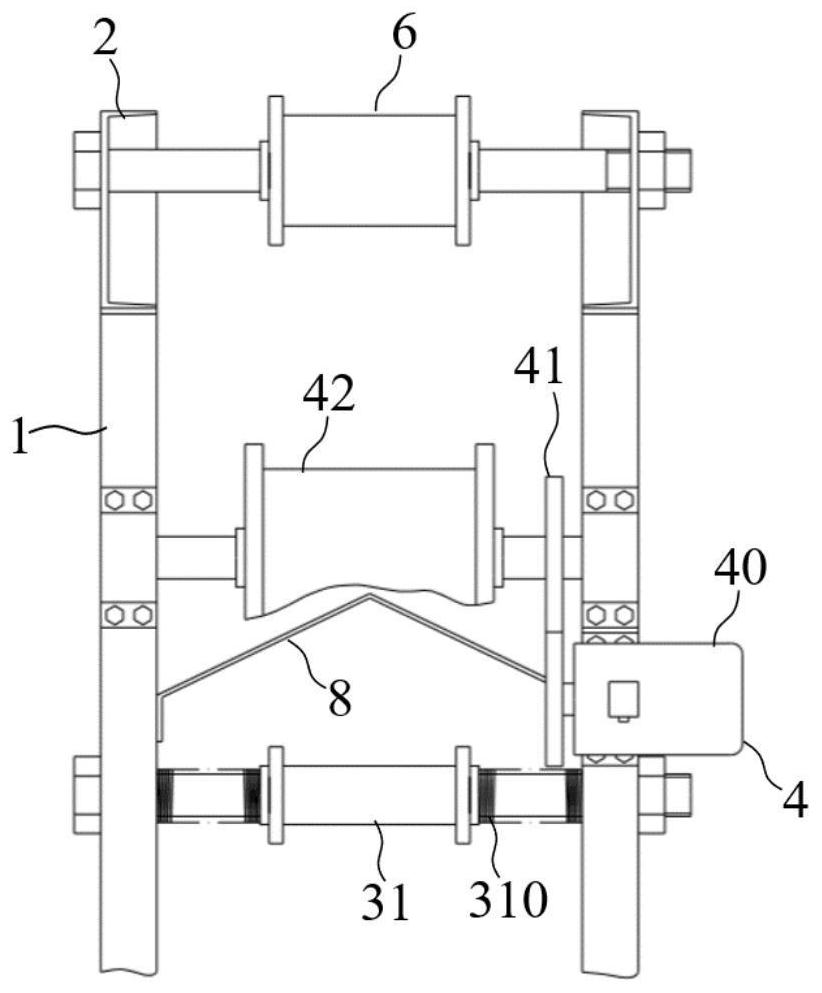

Correction device of pipe belt conveyor

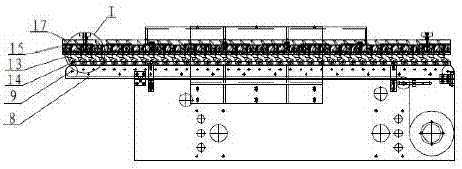

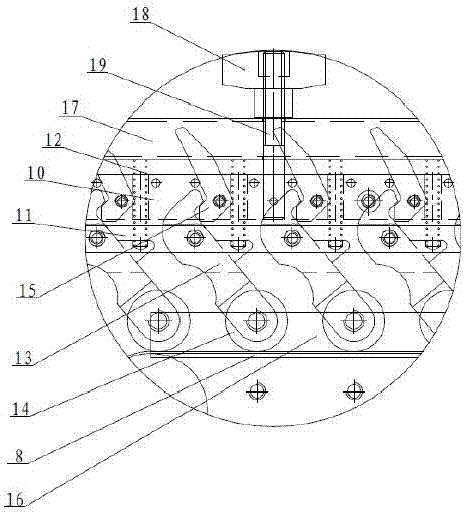

An embodiment of the invention discloses a correction device of a pipe belt conveyor. The correction device comprises a supporting base, a telescopic device hinged to the supporting base through a first hinge shaft, a carrier roller base and an adjustable carrier roller. The telescopic device is hinged to one side of the carrier roller base through a second hinge shaft. The adjustable carrier roller is rotatably arranged on the carrier roller base and is attached to a pipe conveyor belt. The first hinge shaft is perpendicular to the axial direction of the pipe conveyor belt and is parallel to the second hinge shaft. The correction device can adjust the angle of the adjustable carrier roller through extending or retracting of the telescopic device according to the deviation angle when the pipe conveyor belt deviates. The rotating direction of the adjustable carrier roller and the running direction of the pipe conveyor belt form a certain angle so that torsion correction force is generated on the pipe conveyor belt, and the purpose of correcting the pipe conveyor belt is achieved.

Owner:LAIWU IRON & STEEL GRP

Indoor model tunnel shields for simulating shield tunneling construction in urban subway

InactiveCN101398986ARealize dynamic real-time simulationComprehensive and realEducational modelsTunnelsArchitectural engineeringShield tunneling

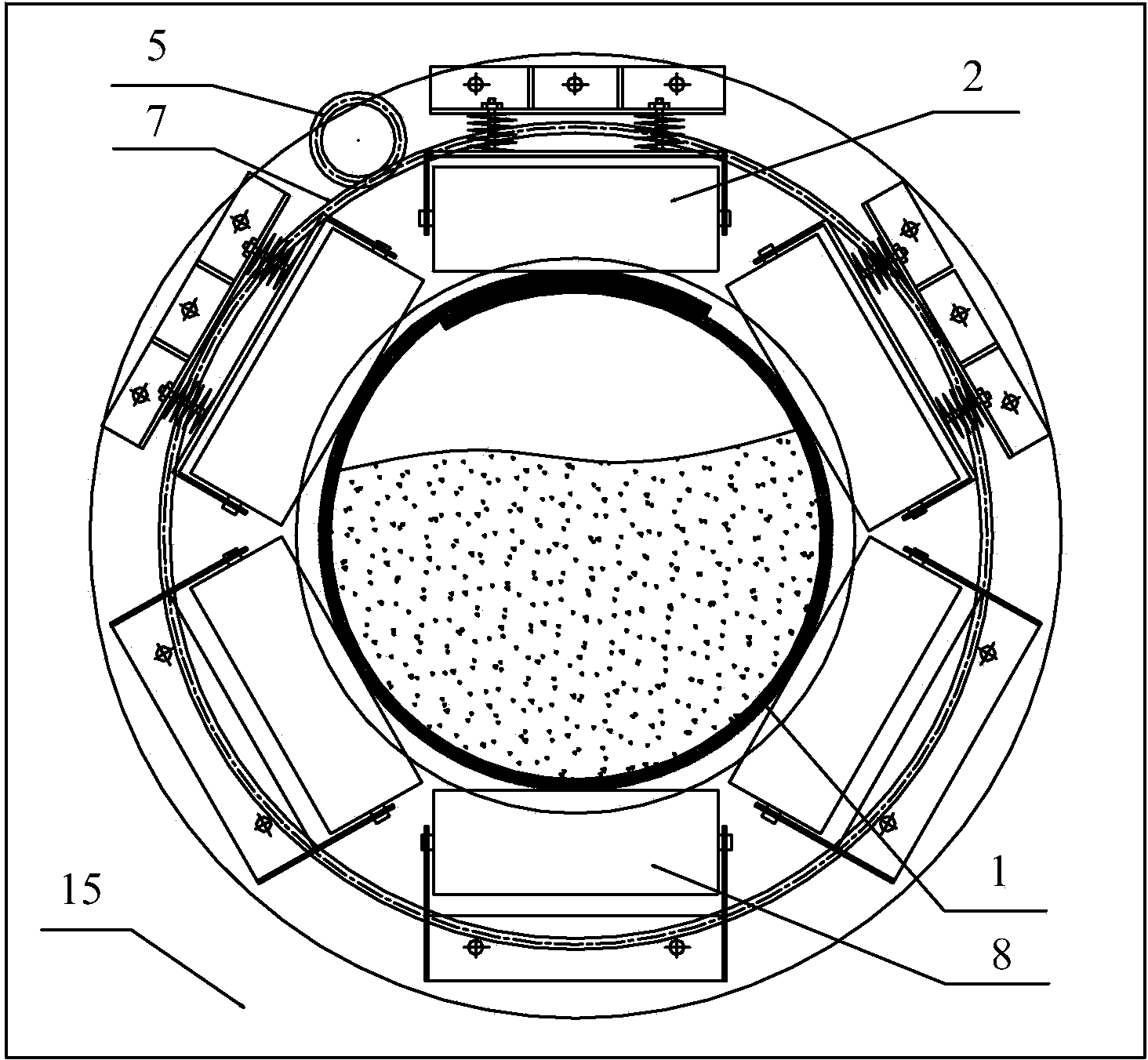

The invention relates to an indoor model shield construction machine used for simulating the interval tunnel shield construction of urban subway, which comprises a digging device, a helix unearthed device and a propelling unit; wherein, a. in the digging device, a round shield shell is separated into a front soil cabin and a rear engine room by a clapboard, a cutter shaft is arranged in the middle of the clapboard by a cutter bearing, the front end of the cutter shaft is connected with a cutter, and the rear end thereof is connected with a cutter motor by a transmission gear; b. in the helix unearthed device, the front part of a screw rod is positioned in the soil cabin at the back of the cutter, the other parts are sheathed in an unearthed sleeve in the engine room by passing through the clapboard, and the rear end of the screw rod is connected with a motor of the unearthed device; the front end and the rear end of the unearthed sleeve are respectively fixed on the clapboard and the engine room, and the rear part thereof is opened with an unearthed hole; c. in the propelling unit, four longitudinal jacks are distributed at the tail end of the engine room; the machine can simulate the whole process of construction of dynamic tunnelling, unearthing, propelling, assembly, decycling and the like, of an earth pressure balanced shield construction machine, provide the real and accurate test data for the tunnel shield construction of the urban subway as for the adaptability or influence of stratum, and guarantee the efficient and safe process of the urban subway construction.

Owner:SOUTHWEST JIAOTONG UNIV

Belt-shape moving body tension differential adjusting and correction method and device therefor

Owner:大连经济技术开发区排水管理有限公司

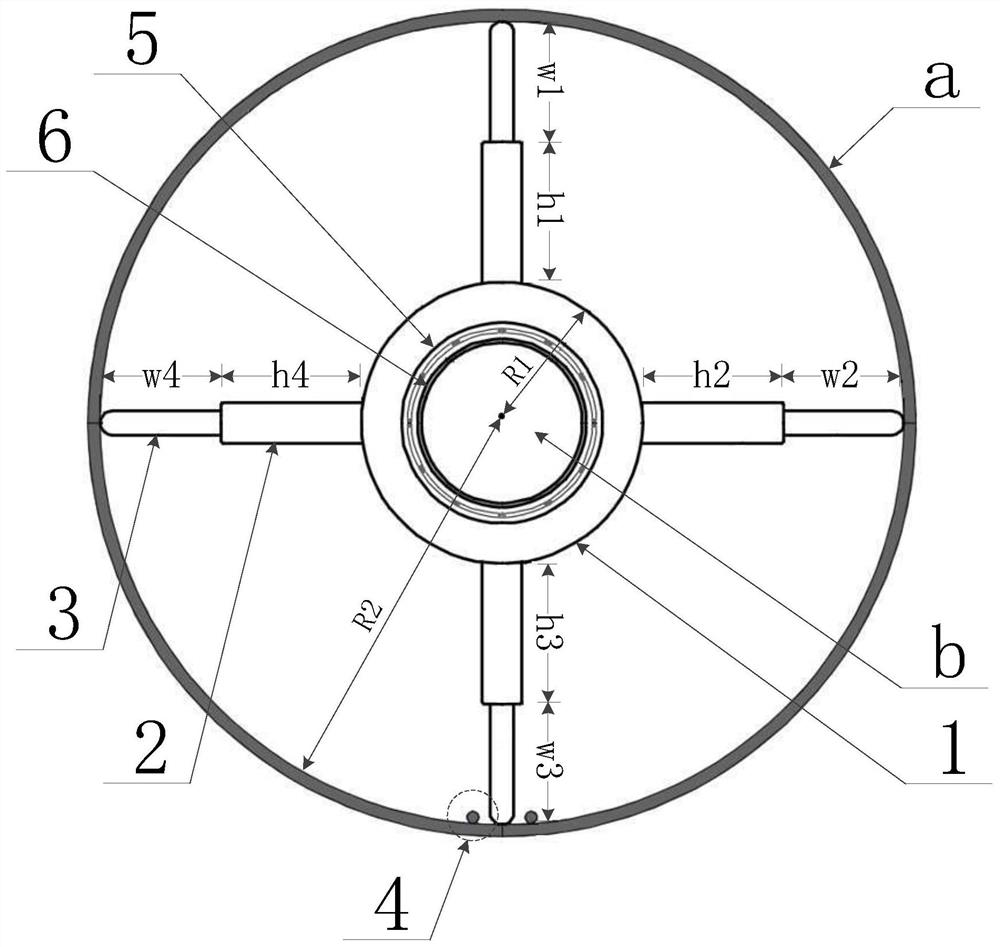

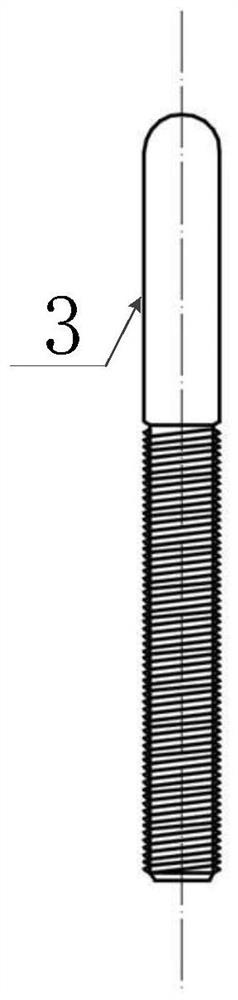

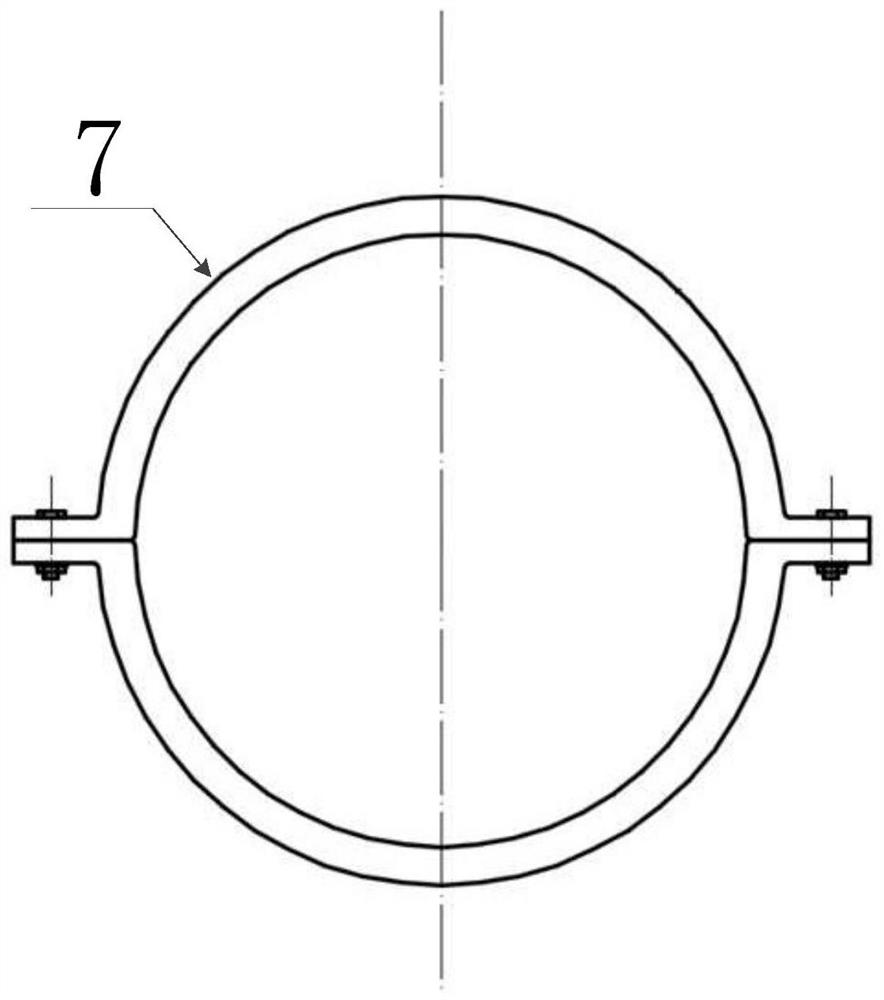

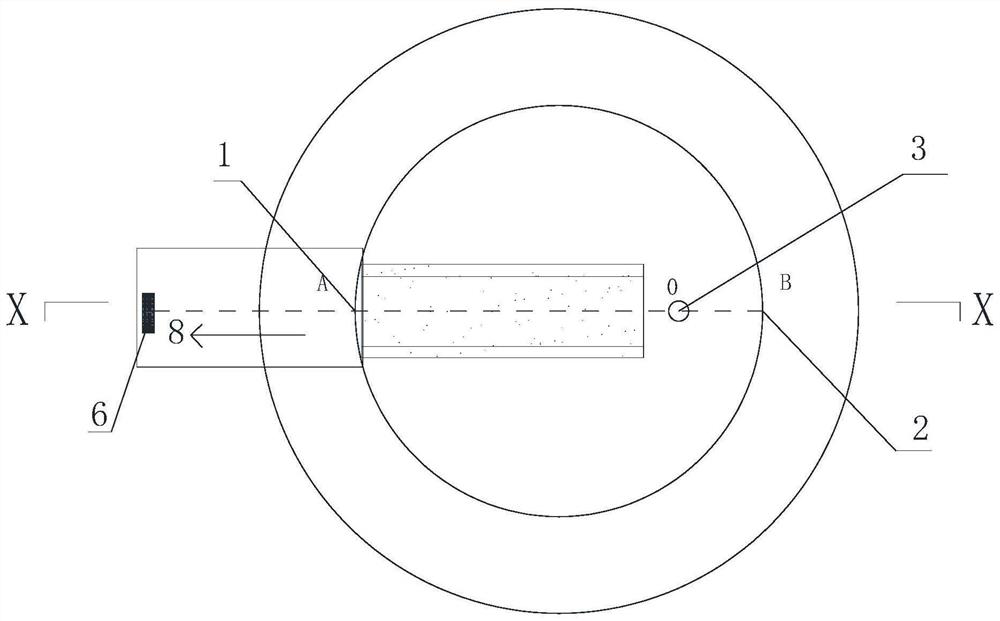

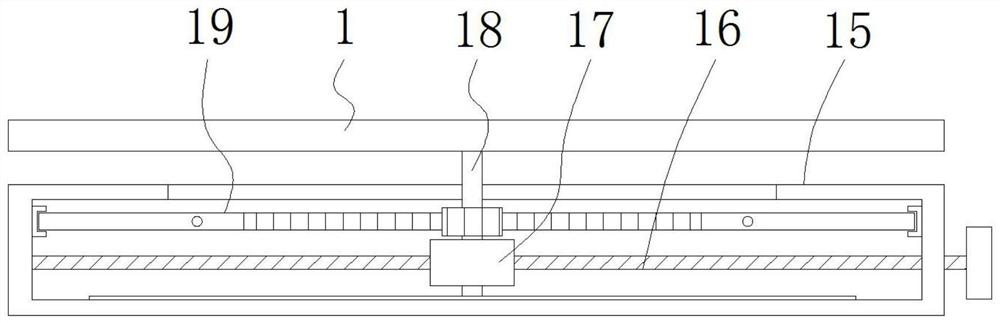

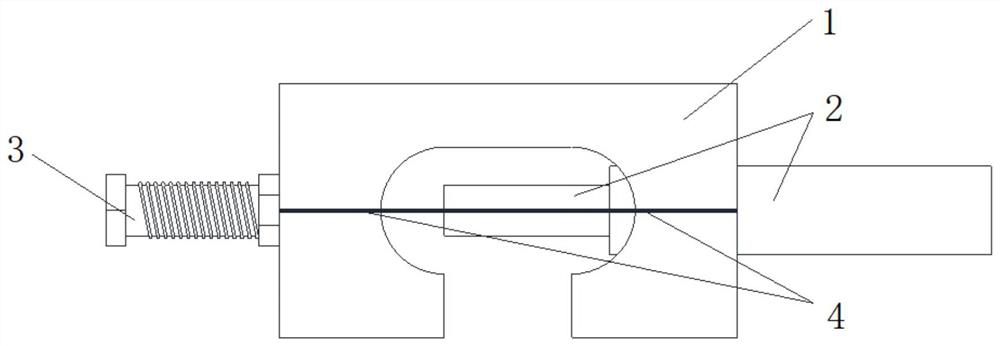

Guiding and rectifying device for sandy cobble stratum pipe shed construction

PendingCN112343509AEasy to controlGuaranteed accuracyUnderground chambersDirectional drillingSteel tubeDrill bit

The invention relates to a guiding and rectifying device for sandy cobble stratum pipe shed construction. The guiding and rectifying device comprises a circular ring and a fixed unit, wherein the circular ring is arranged in a pipe shed steel pipe, the axis of the circular ring is parallel to that of the pipe shed steel pipe, a guiding hole for a drill pipe to penetrate through is formed in the circular ring, and the drilling of the drill pipe is guided and rectified through the guiding hole; and the fixed unit is arranged on the outer side surface of the circular ring, is arranged between thecircular ring and the pipe shed steel pipe and is used for keeping the axis of the circular ring parallel to the axis of the pipe shed steel pipe. The guiding and rectifying device for the sandy cobble stratum pipe shed construction has the beneficial effects that the guiding and rectifying device is matched with sandy cobble stratum super-long pipe shed construction, and the axis position of thedrill pipe can be controlled, so that the drilling direction of a drill bit can be controlled, and the precision of the drilling direction is guaranteed in a construction process; and additionally, when the drilling direction deviates, the axis direction of the drill pipe is adjusted by adjusting the extension length of a screw rod, so that the drilling direction of the drill bit is changed, andthe deviation rectifying purpose is achieved.

Owner:GUANGZHOU METRO DESIGN & RES INST

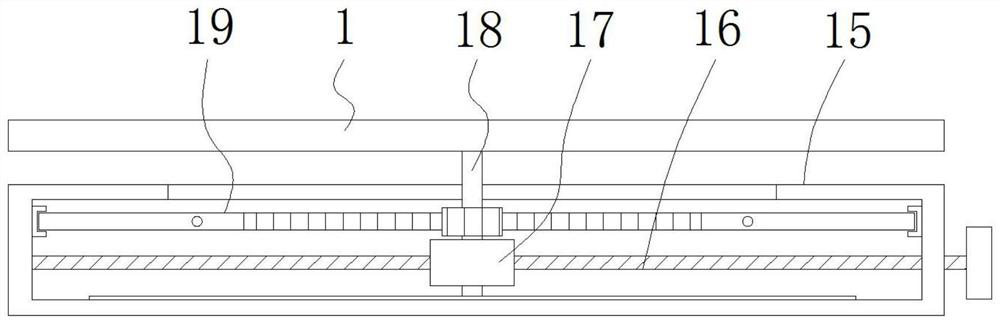

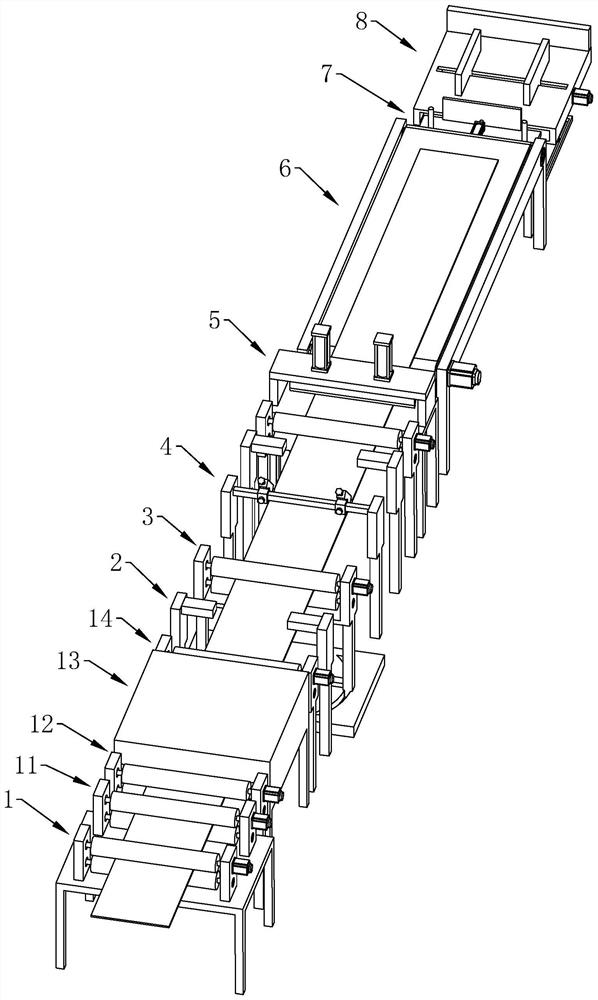

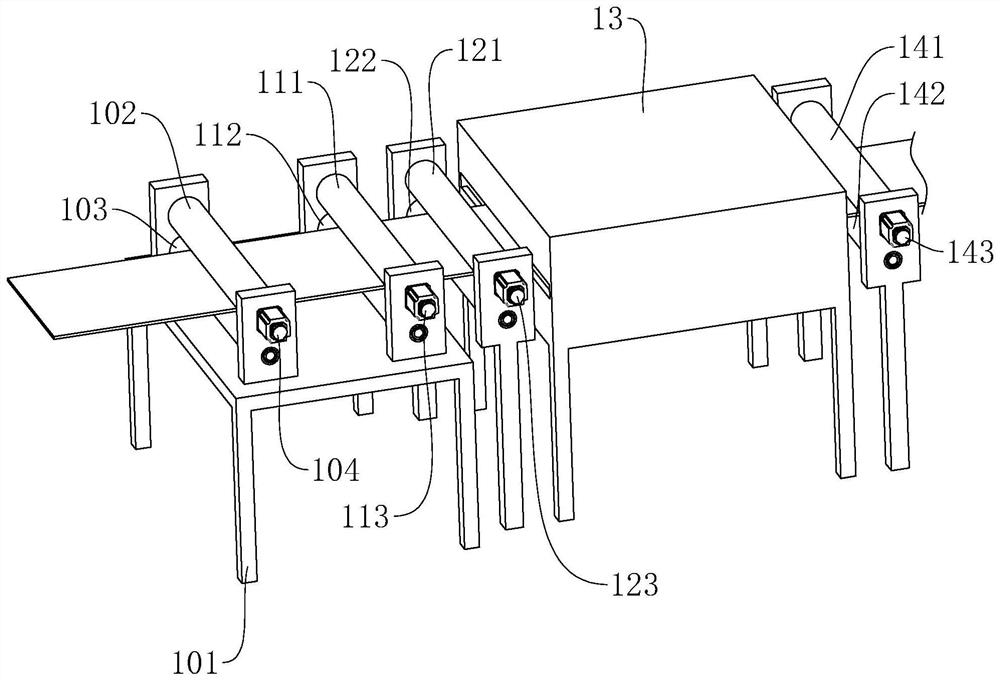

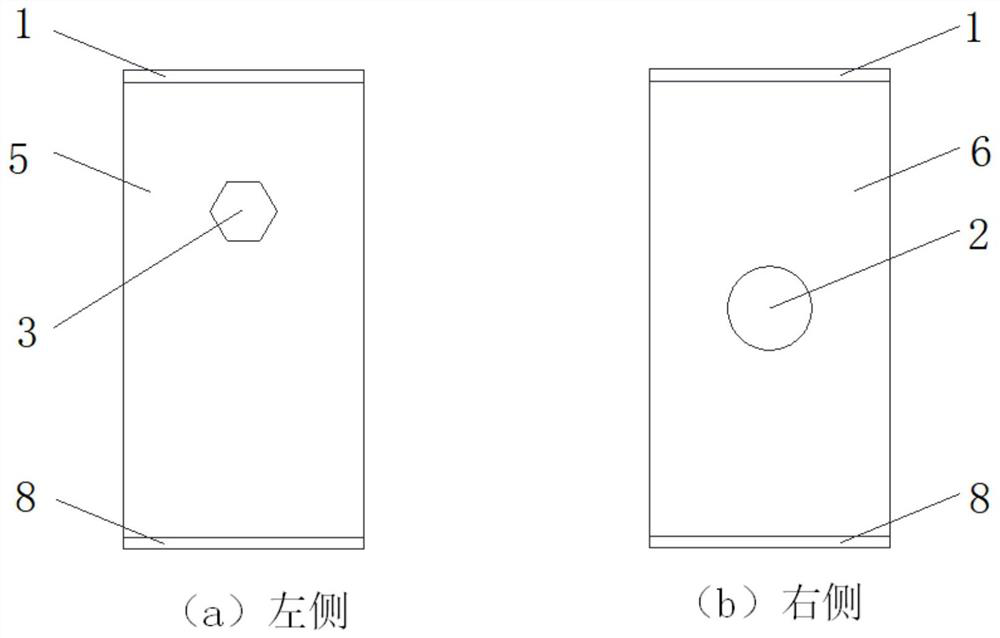

Plate deviation correction device and deviation correction method

PendingCN109592363AAvoid damageTo achieve the purpose of correctingConveyor partsCorrection methodEdge detector

The invention discloses a plate deviation correction device and a deviation correction method. According to the scheme, the plate deviation correction device comprises a conveying underframe. A detection area and a deviation correction area are arranged on the conveying underframe. A supporting cross beam and two plate edge detectors are arranged in the detection area. The supporting cross beam isarranged above the conveying underframe. The plate edge detectors are symmetrically arranged along the center of the conveying underframe. Two sets of conveying assemblies symmetrically arranged along the center of the conveying underframe are arranged in the deviation correction area. The conveying assemblies independently operate to support plates to be conveyed forwards, the plate edge detectors detect the conveying state of the plates, and two sets of conveying belts support the plates to be conveyed forwards and independently operate. When deviation correction is needed, the operation speeds of the two sets of conveying assemblies are different by adjusting the operation speeds of the two sets of conveying assemblies, the operation state of the plates is adjusted through the speed difference between the two sets of conveying assemblies, and the aim of deviation correction is achieved. In the process of deviation correction, damage to the plates and the influence on the conveyingspeed of the plates are reduced.

Owner:KEDA INDUSTRIAL GROUP CO LTD

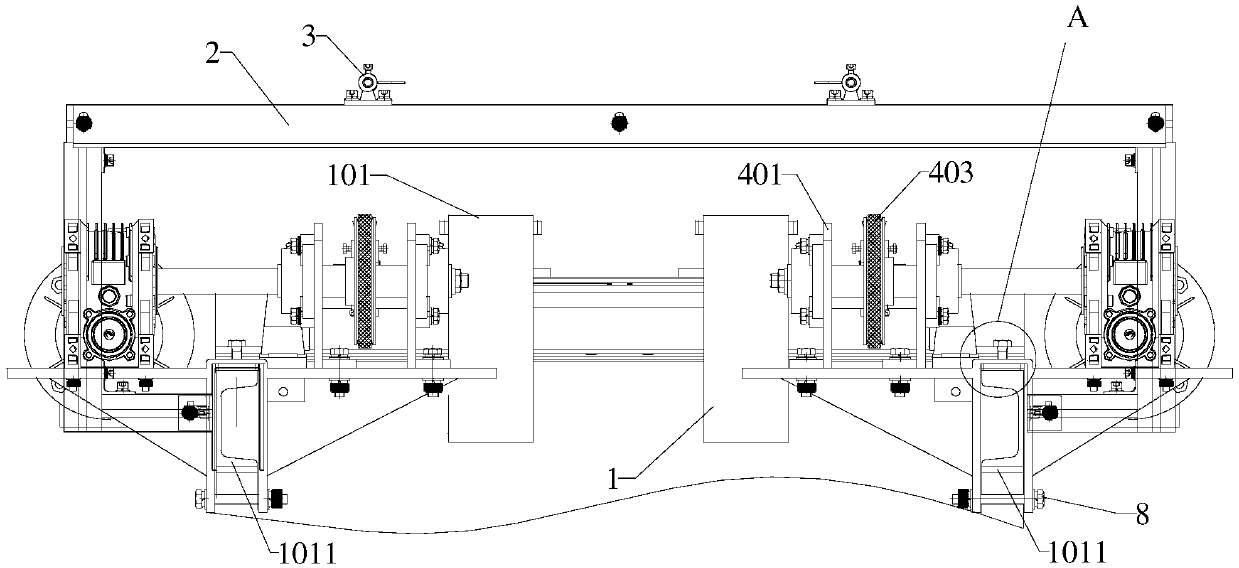

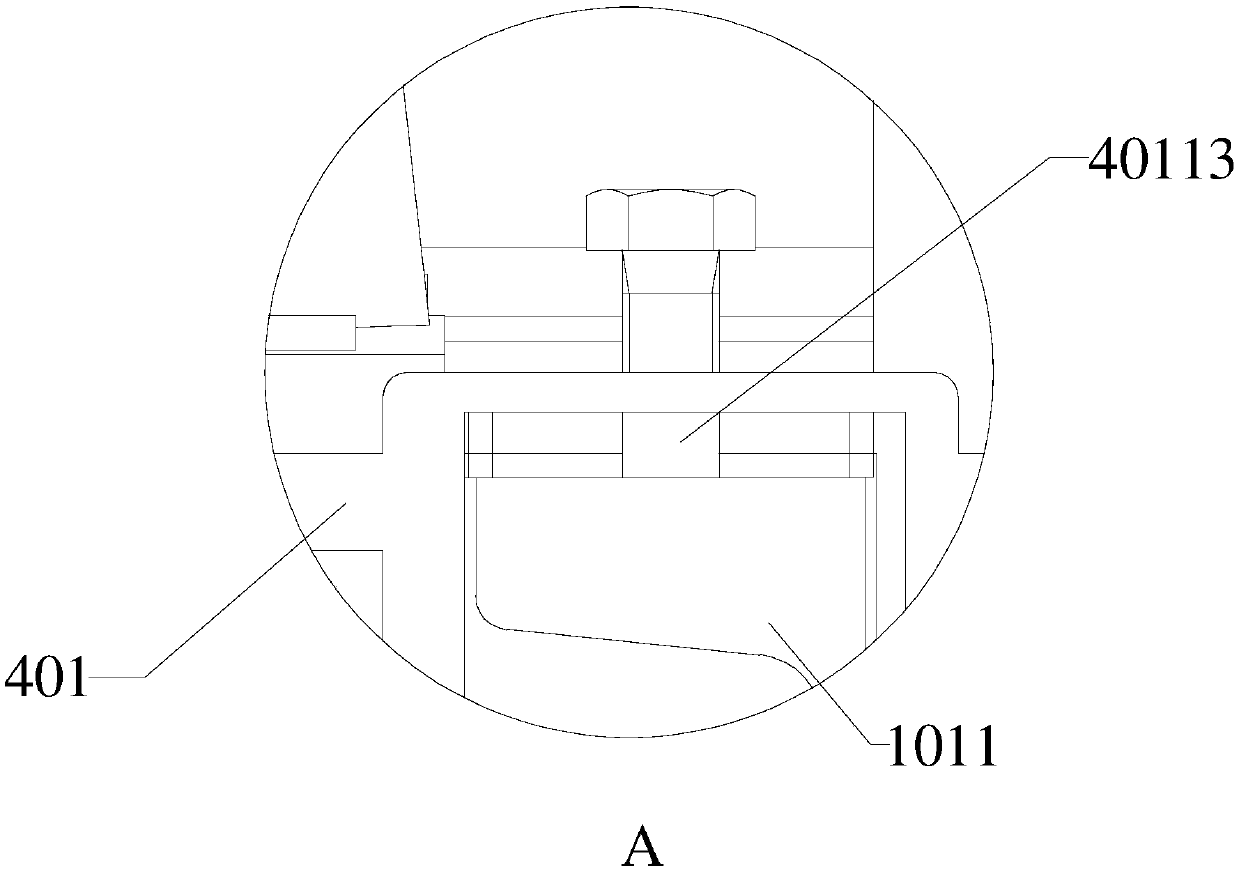

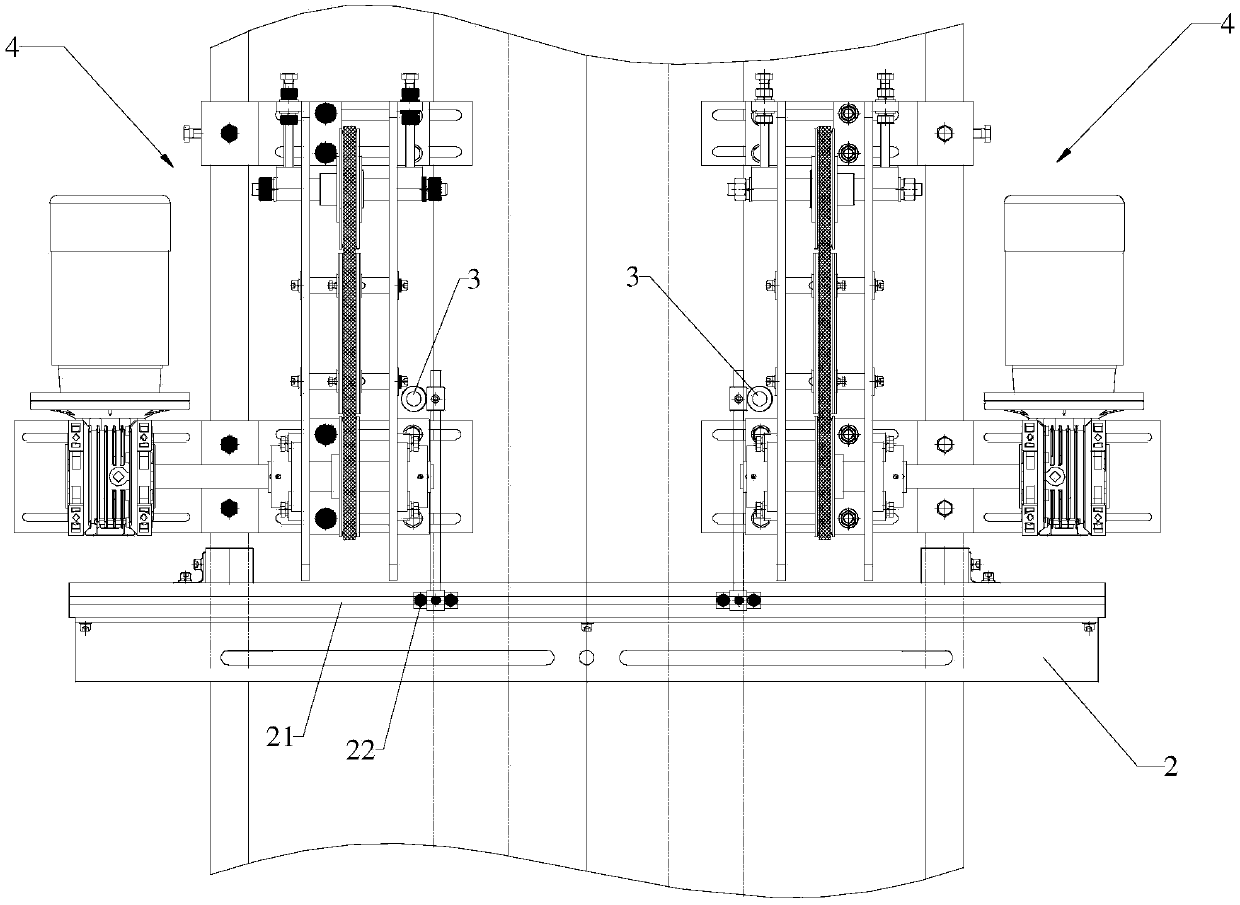

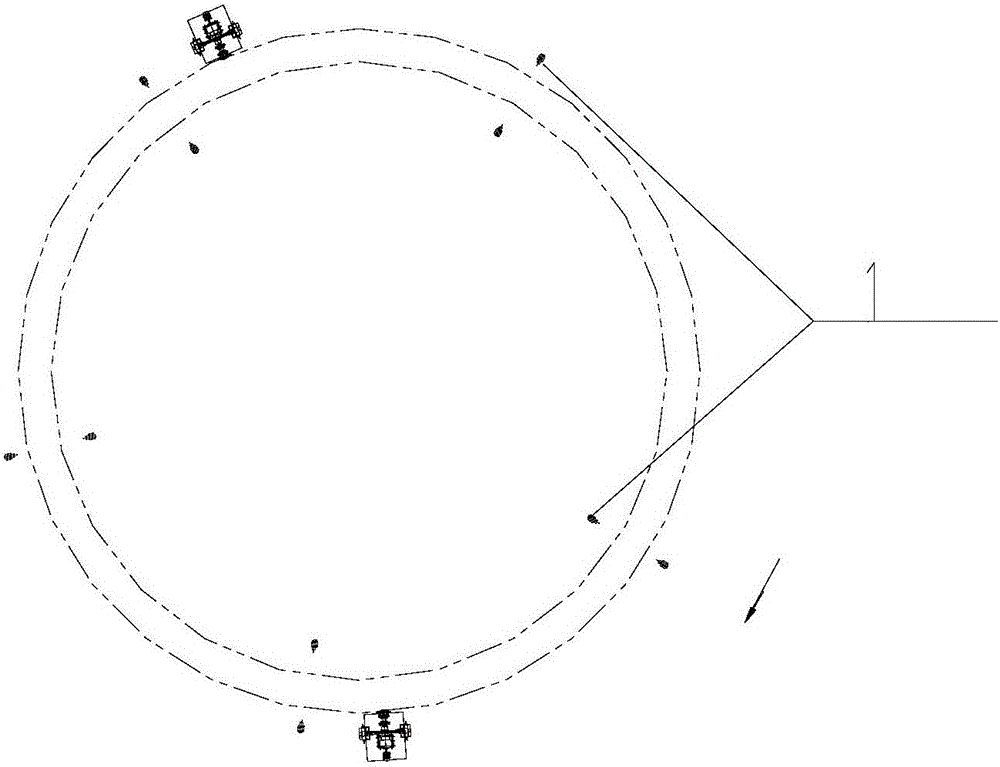

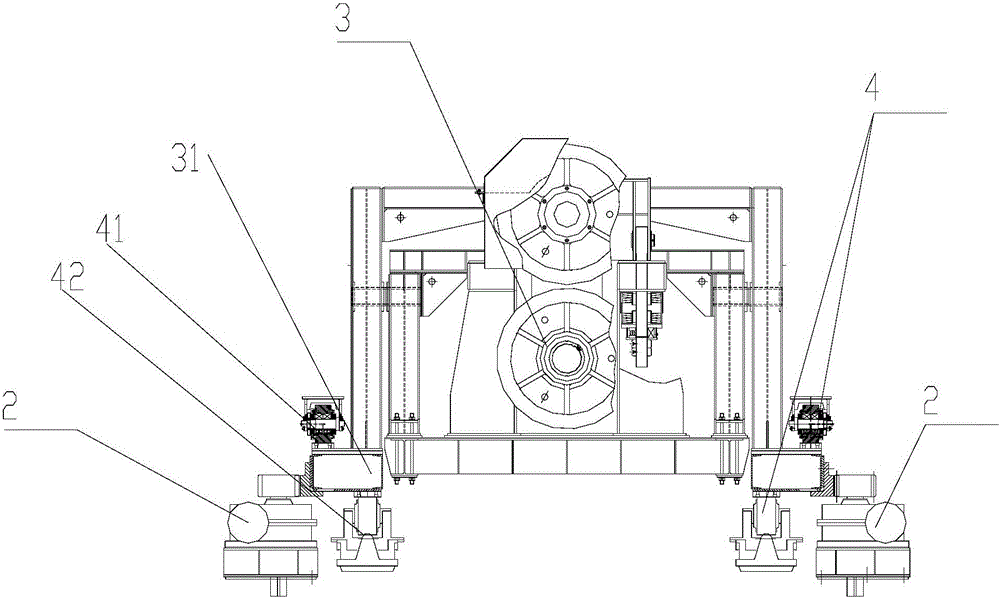

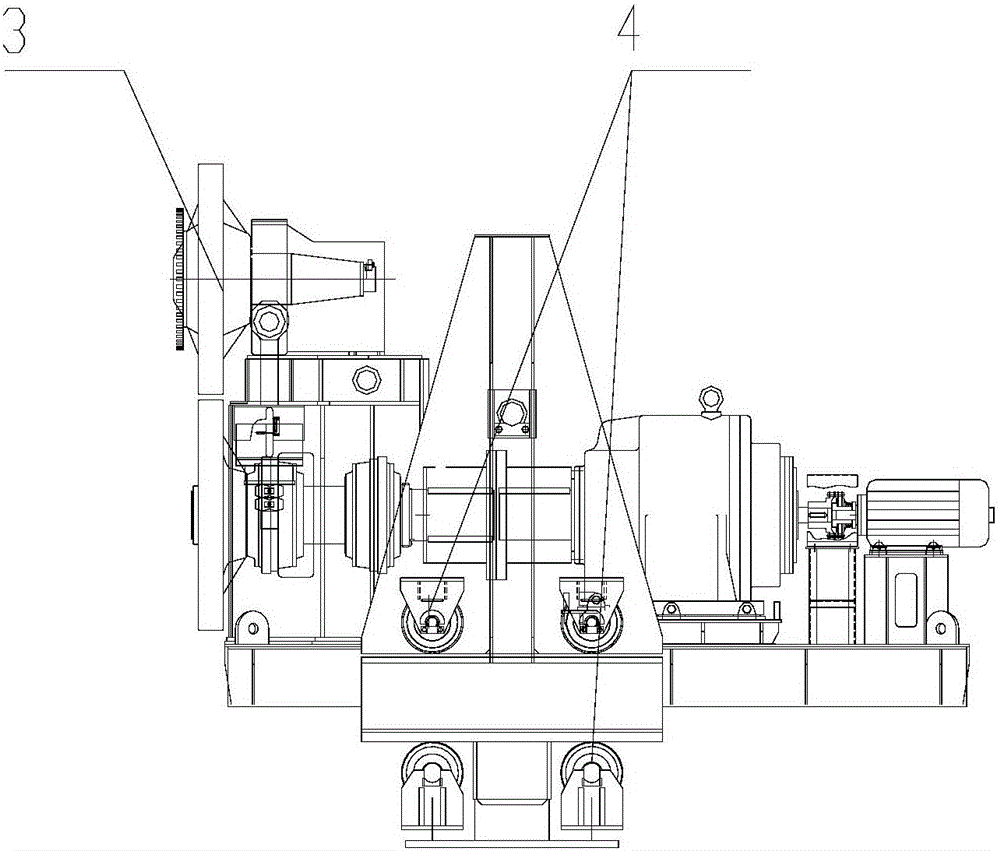

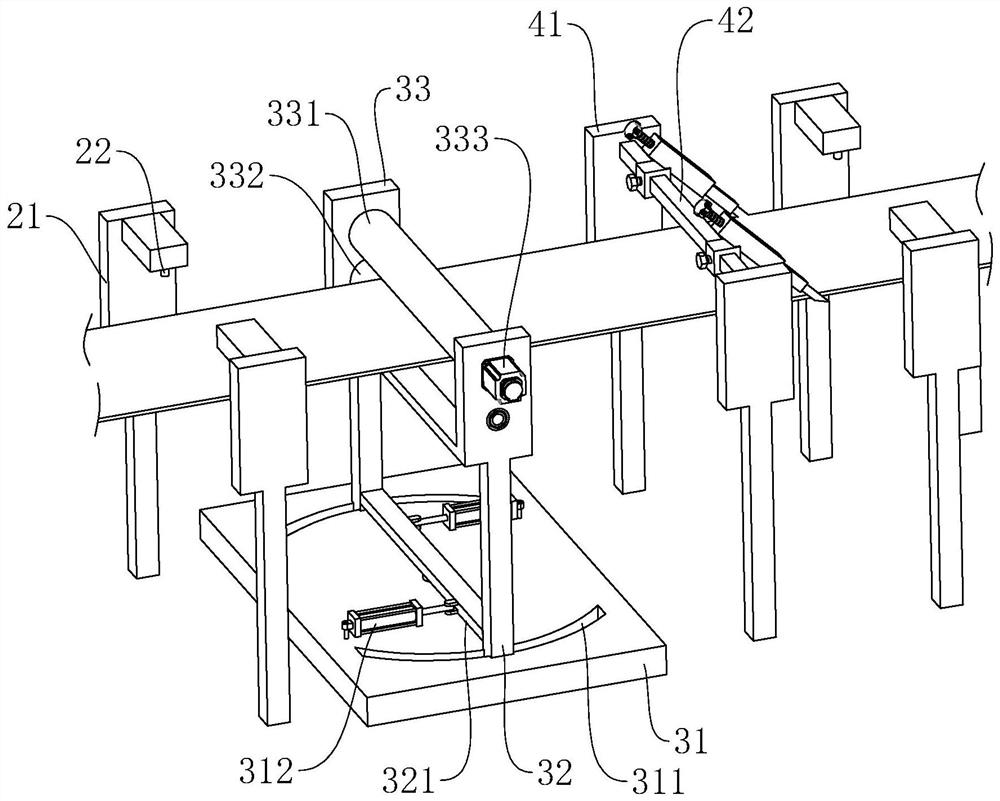

Ring cooling machine transmission device with automatic deviation rectifying function

ActiveCN105823343ATo achieve the purpose of correctingFurnace typesHandling discharged materialEngineeringMechanical engineering

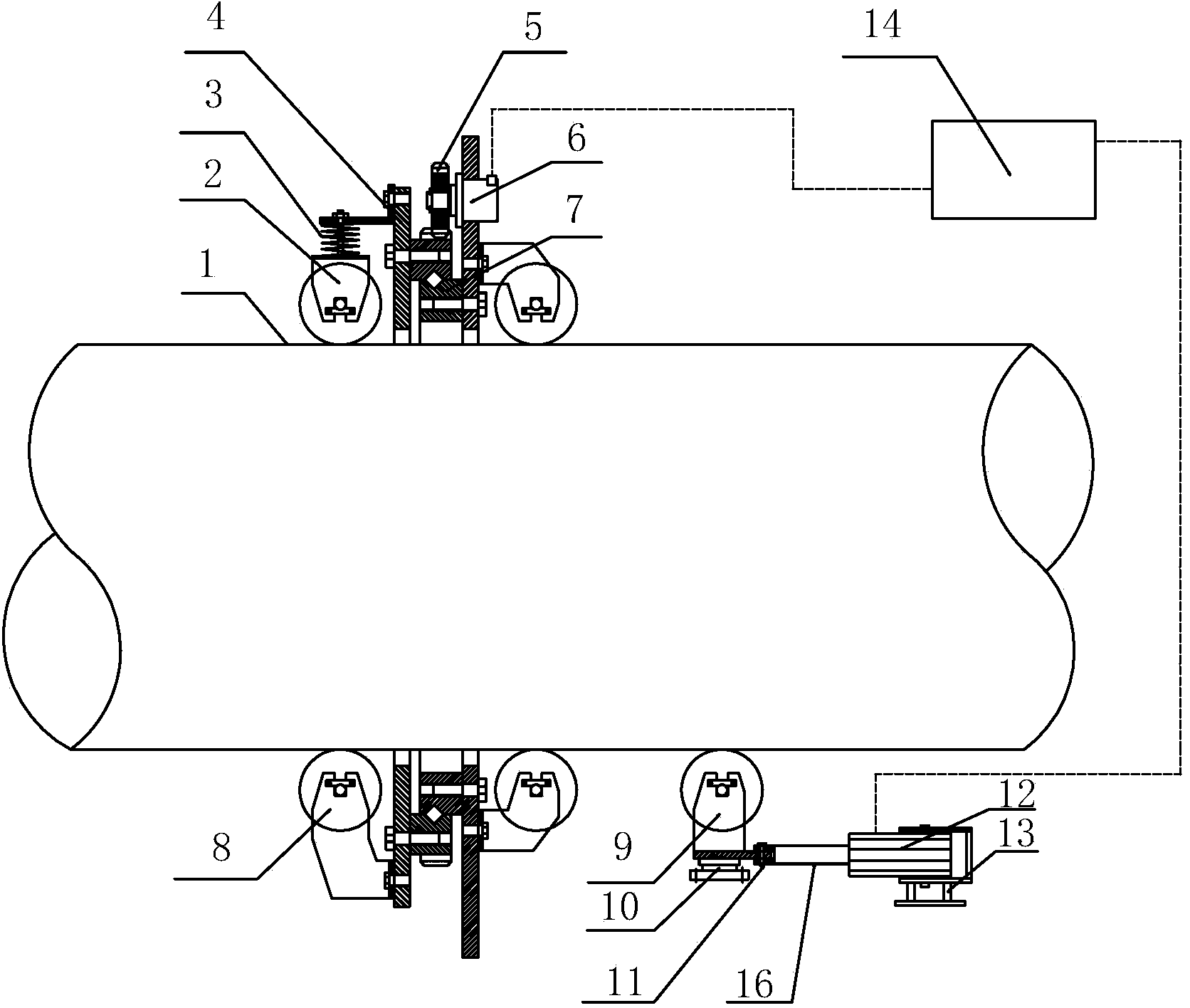

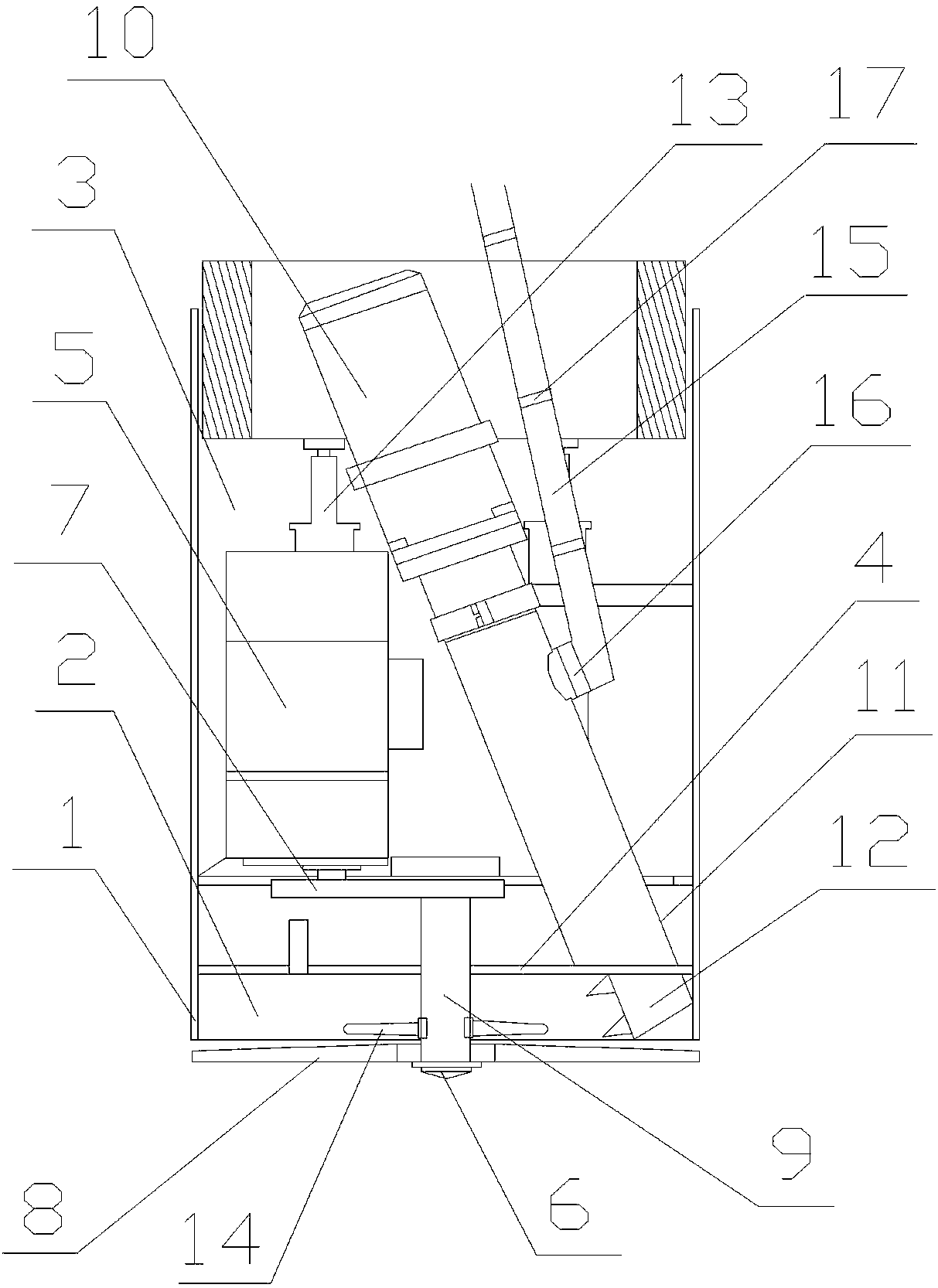

The invention discloses a ring cooling machine transmission device with an automatic deviation rectifying function, and provides a ring cooling machine transmission device which is capable of rectifying deviation automatically and mainly solves the problem of deviation of a frame of a rotating body of a ring cooling machine. The ring cooling machine transmission device with the automatic deviation rectifying function comprises measuring components, turning components, a driving component and supporting components. According to the ring cooling machine transmission device with the automatic deviation rectifying function, after measuring and detecting deviation of the rotating body, the measuring components transmit signals for controlling the turning components, the turning components drive the driving component to rotate, and after the driving component is driven to rotate, a driving force will generate a lateral component force to adjust the position of the rotating body; and the measuring components can transmit signals to control the turning components according to the position of the adjusted rotating body, and the turning components adjust the position of the rotating body again by driving the driving component to rotate. The turning components continuously adjust the driving component so that the optimal position of the rotating body can be controlled dynamically, so that the purpose of rectifying deviation of the ring cooling machine is achieved.

Owner:HUATIAN ENG & TECH CORP MCC

An automatic folder gluer

ActiveCN103991240BOvercome the scrap problemTo achieve the purpose of correctingBox making operationsPaper-makingCardboardEconomic benefits

Owner:WENZHOU ZIHONG PRINTING PACKAGING MACHINERY

Novel efficient subway construction shield device

The invention discloses a novel efficient subway construction shield device which comprises a cylindrical shield shell, a cutter driving motor, a cutter bearing, a cutter shaft, stirring blades, a soil discharge driving motor, a soil discharge sleeve, a spiral soil discharge rod, hydraulic jacks and a muck conveying pipeline. The inside of the shield shell is divided into a soil cabin and an engine cabin by a shifting board, the cutter shaft is matched with a cutter and connected with the cutter, the stirring blades are arranged on the cutter shaft, the soil discharge driving motor and the soil discharge sleeve are fixed into the engine cabin, the spiral soil discharge rod is arranged in the soil discharge sleeve and the soil cabin, the hydraulic jacks are fixed to the inner side of the shield shell, the muck conveying pipeline is communicated with the soil discharge sleeve, a compressed air cut-in valve is arranged on the muck conveying pipeline, lubricating medium inlets are formed in the muck conveying pipeline every 3-4 meters, oil lines of the four hydraulic jacks are serially connected into a group by two opposite hydraulic jacks, two jack groups are parallelly connected, andthe cutter is in the shape of a spoke or panel. The novel efficient subway construction shield device solves the problems that soil is not smoothly discharged, a construction site is easily polluted,and construction efficiency is low in the prior art.

Owner:陈明

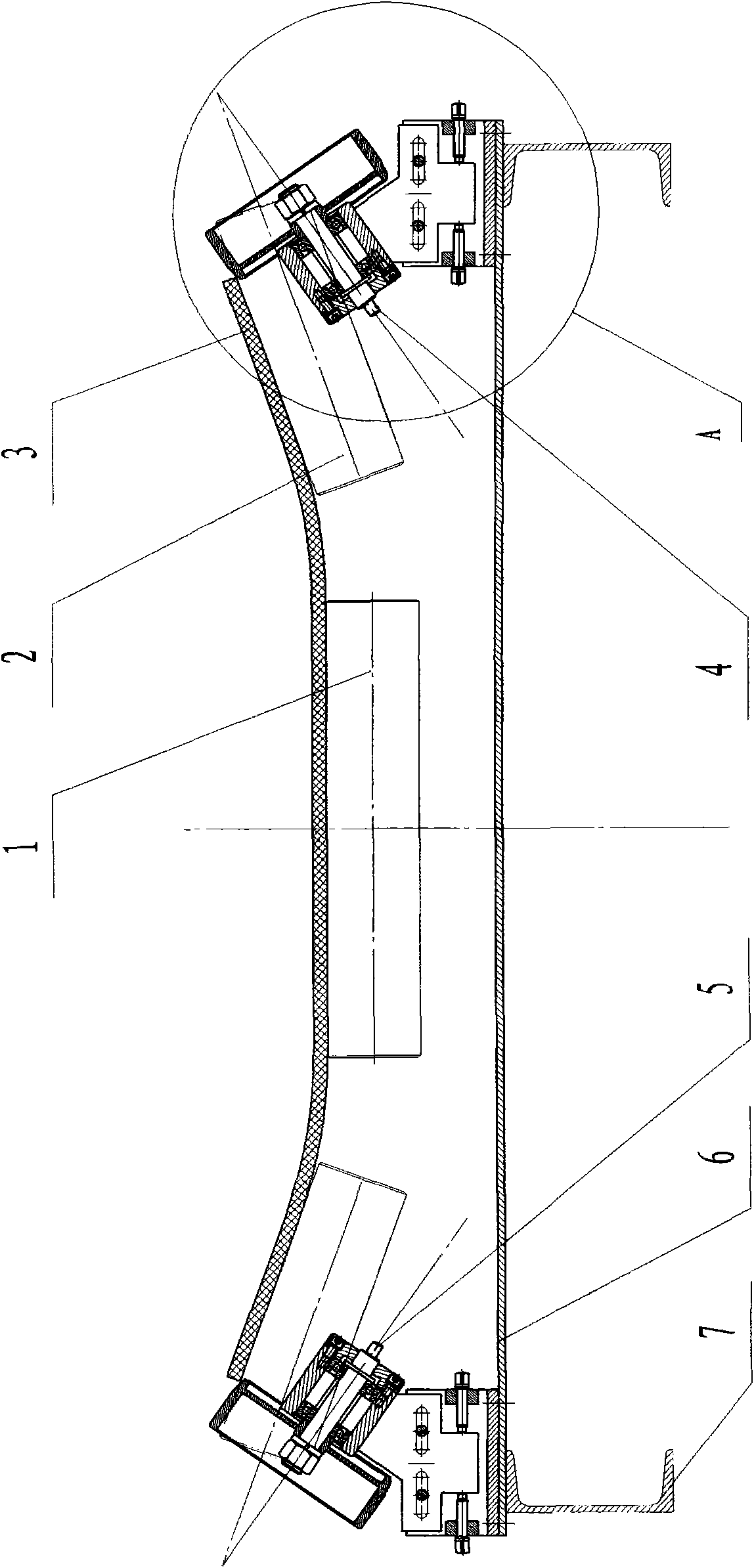

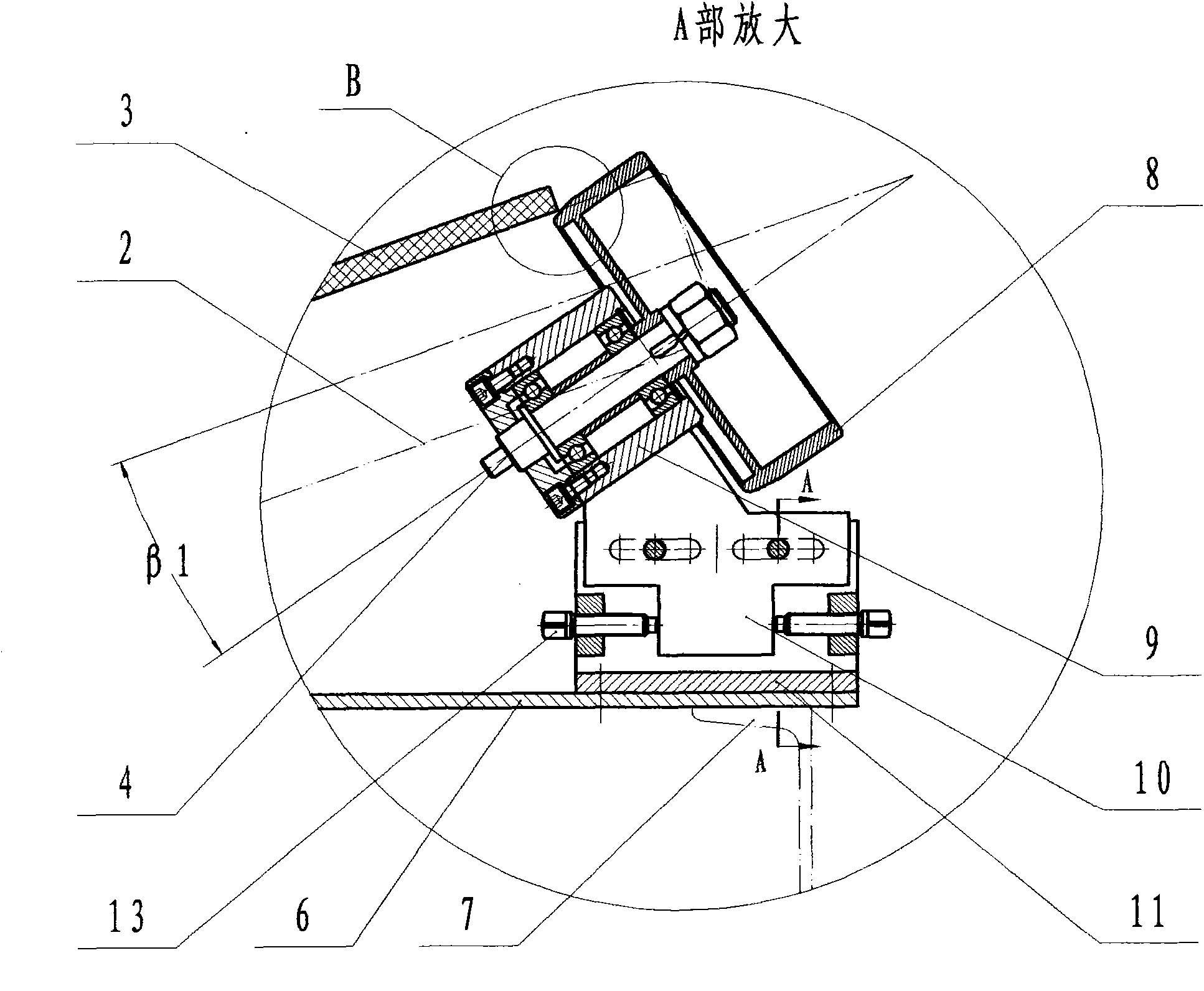

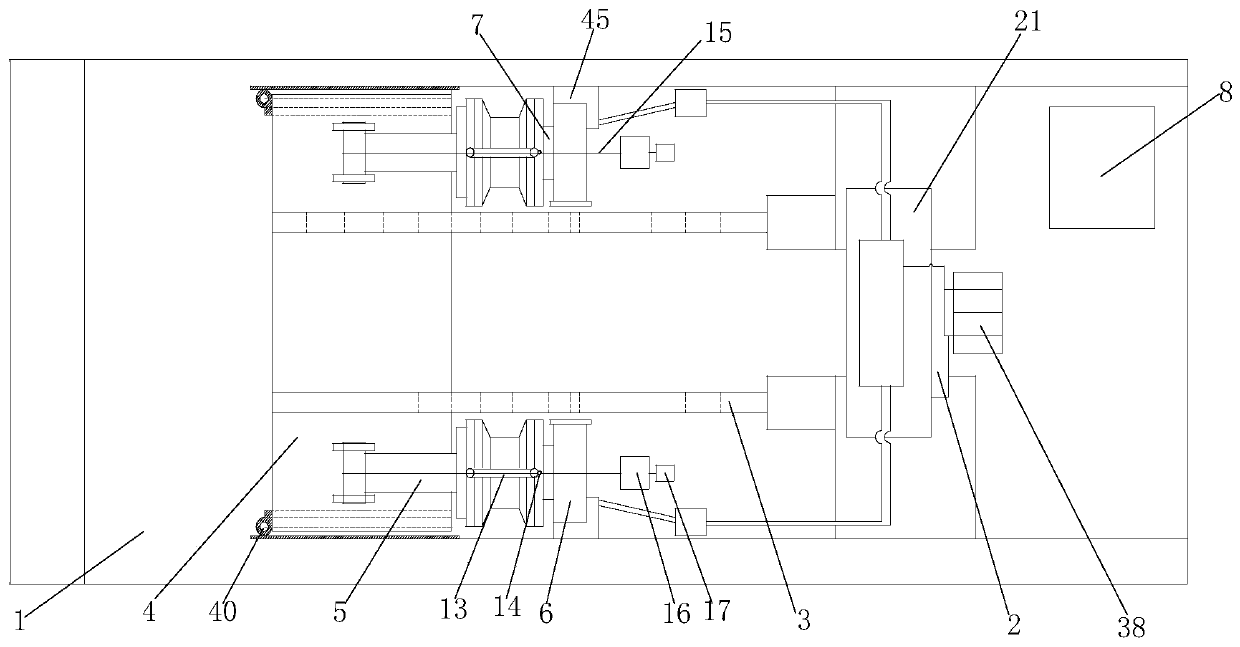

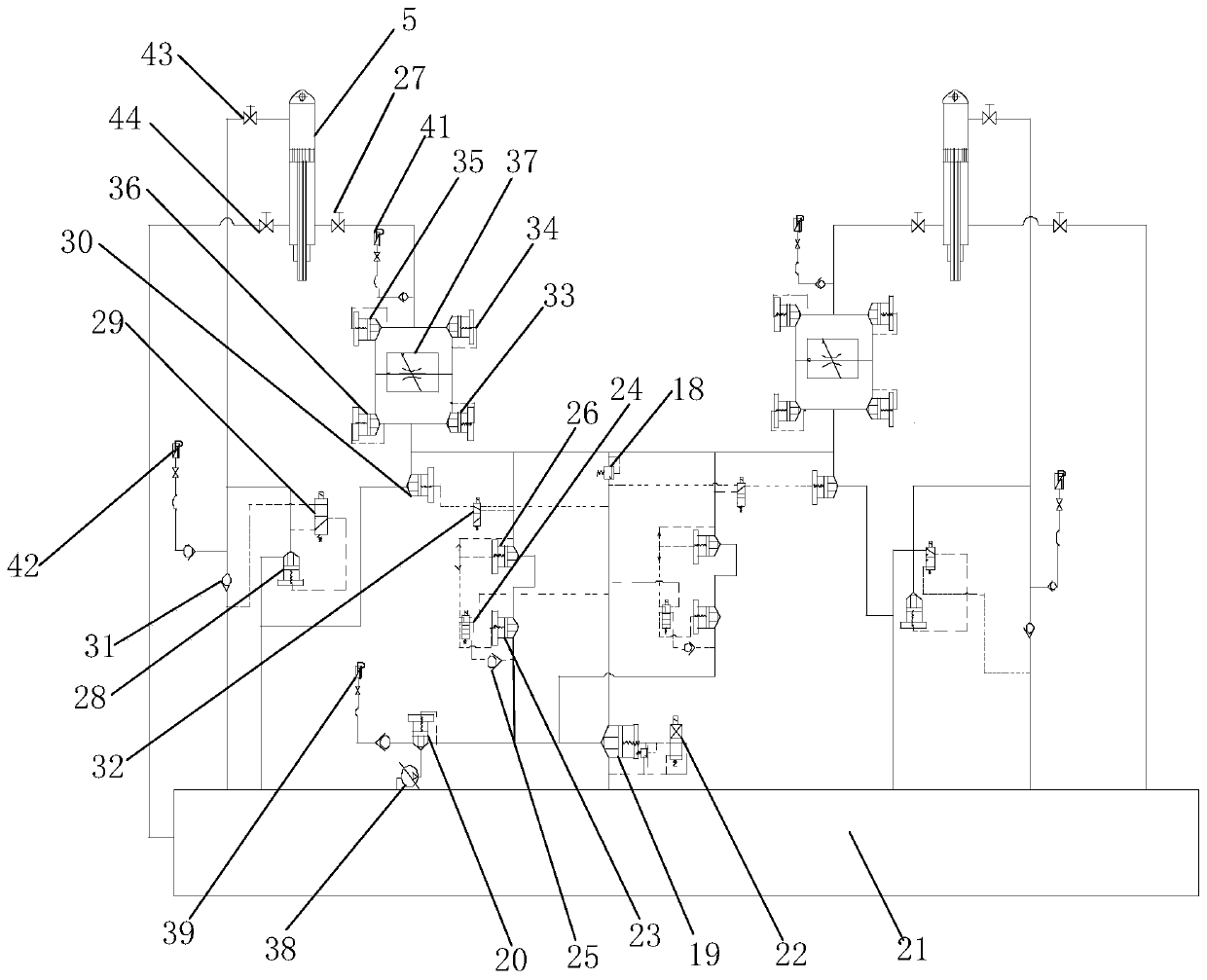

Automatic rectification machine for belt conveyer

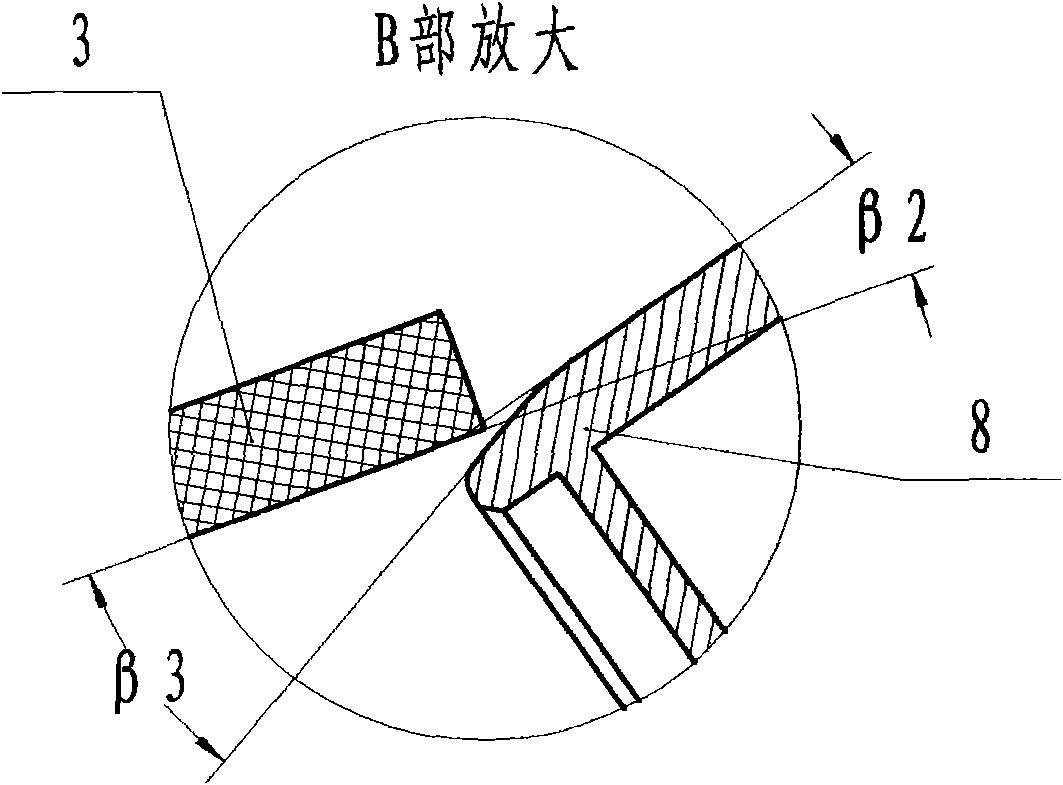

The invention discloses an automatic rectification machine for a belt conveyer, which is characterized by consisting of an oil pump, a hydraulic system and a detection roller component, wherein a front cover of the oil pump is provided with double input shafts, and a rear cover of the oil pump is provided with a cartridge valve plate; the detection roller component consists of a detection roller output shaft, a detection roller, a bearing sleeve, a bearing sleeve connecting plate, a detection roller seat frame, a fastening bolt and a positioning screw; the front end of the detection roller is formed into a cone, and an included angle beta1 is formed between the axis of the detection roller and an inclined roller of the belt conveyer; and the detection roller output shaft is connected with the input shafts of the oil pump through a soft shaft. When a belt of the belt conveyer deflects and touches the detection roller, the detection roller rotates under the action of friction torque and, through the detection roller output shaft, the soft shaft and the input shafts of the pump, drives the oil pump to operate to input pressure oil to an oil cylinder, the oil cylinder drives a rectification roller bracket to rotate under the action of the pressure oil, and a rectification roller on the bracket rectifies and resets the belt so as to fulfill the aim of rectification.

Owner:王振孝

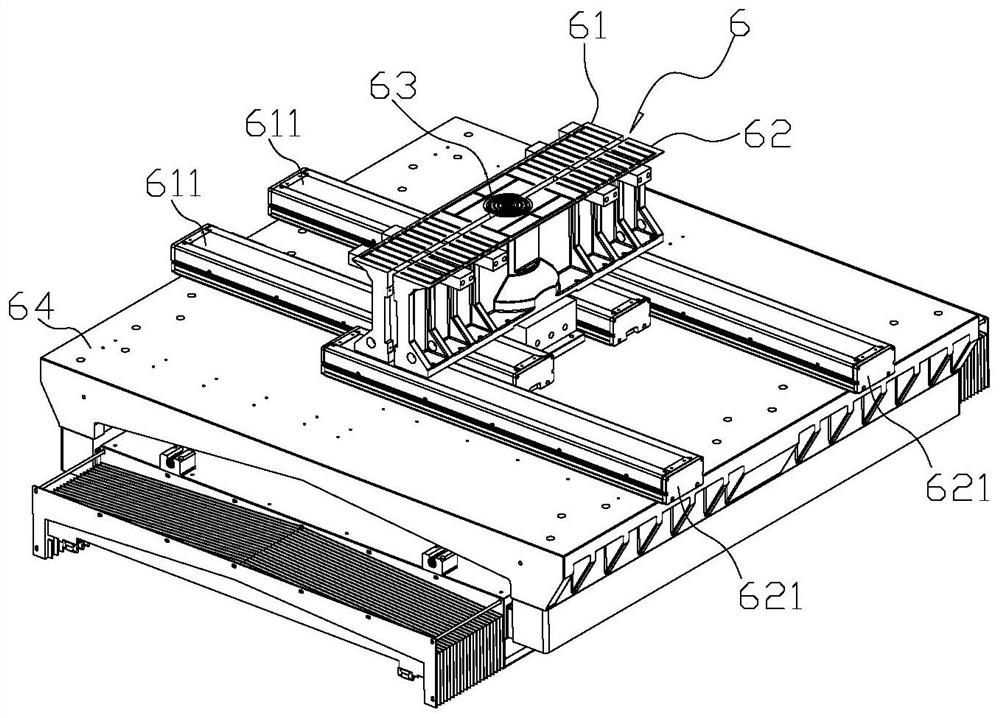

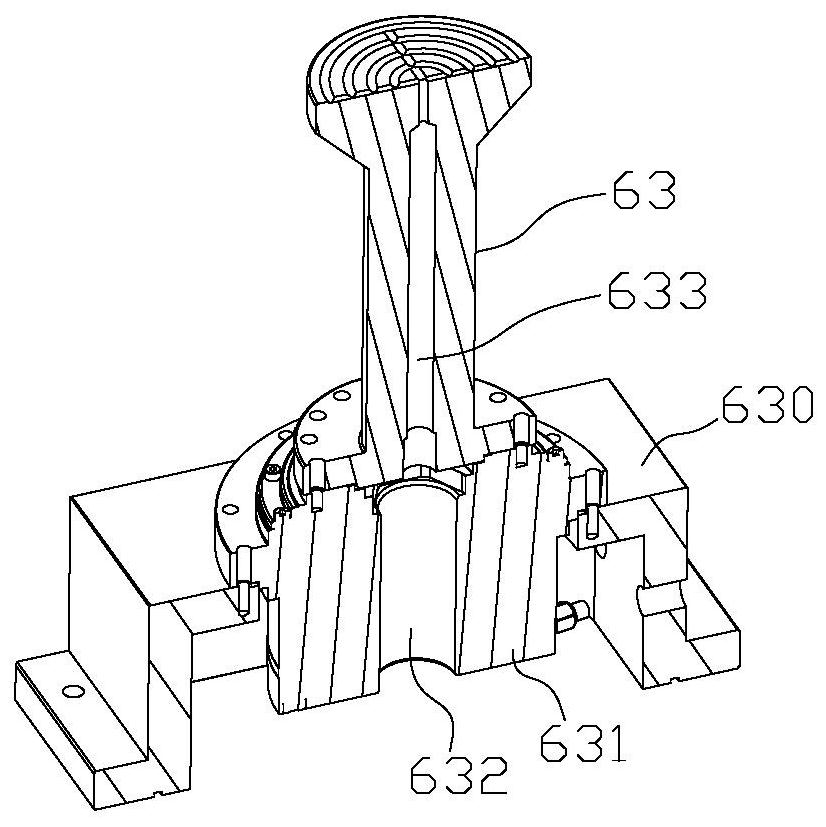

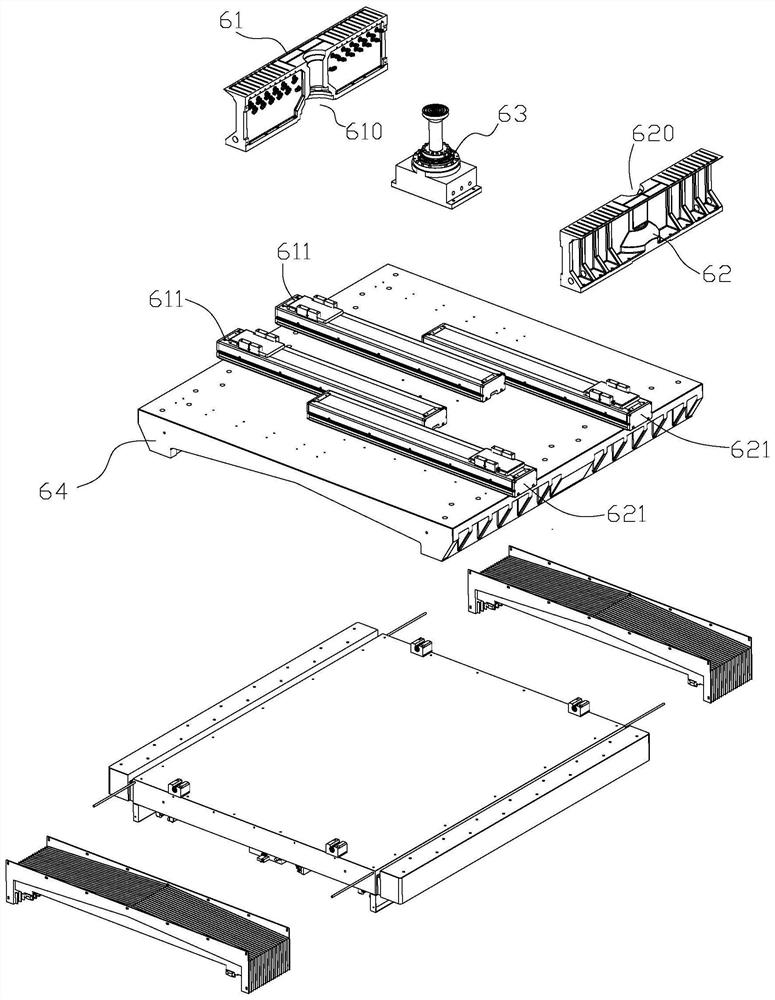

Glass bearing module with deviation rectifying function

ActiveCN112975644AEnough supportResolve fragmentationEdge grinding machinesGrinding carriagesFlat glassEngineering

The invention discloses a glass bearing module with a deviation rectifying function. The glass bearing module comprises a carrying base, a first movable base, a second movable base and a rotating base, wherein the first movable base and the second movable base are installed on the carrying base and can relatively run, the rotating base is used for matching with the first movable base and the second movable base to bear glass or rectify deviation of the glass, the first movable base and the second movable base are driven by respective driving mechanisms to move in the transverse direction, vacuum adsorption holes or channels are formed in the upper surfaces of the first movable base, the second movable base and the rotating base, when the angles of the glass borne by the first movable base and the second movable base are wrong, the vacuum adsorption holes or channels of the first movable base and the second movable base blow air to the two ends of the glass correspondingly, so that the glass is in a suspended state, and at the moment, the glass can be adsorbed through the rotating base and is driven to rotate by a certain angle for correction, and correction is achieved. According to the glass bearing module, the glass can be sufficiently supported, the problem that the glass is broken due to possible stress concentration is solved, and the glass bearing module can adapt to polishing of plate glass of different sizes.

Owner:SHENZHEN JOJOY BEN MACHINERY EQUIP

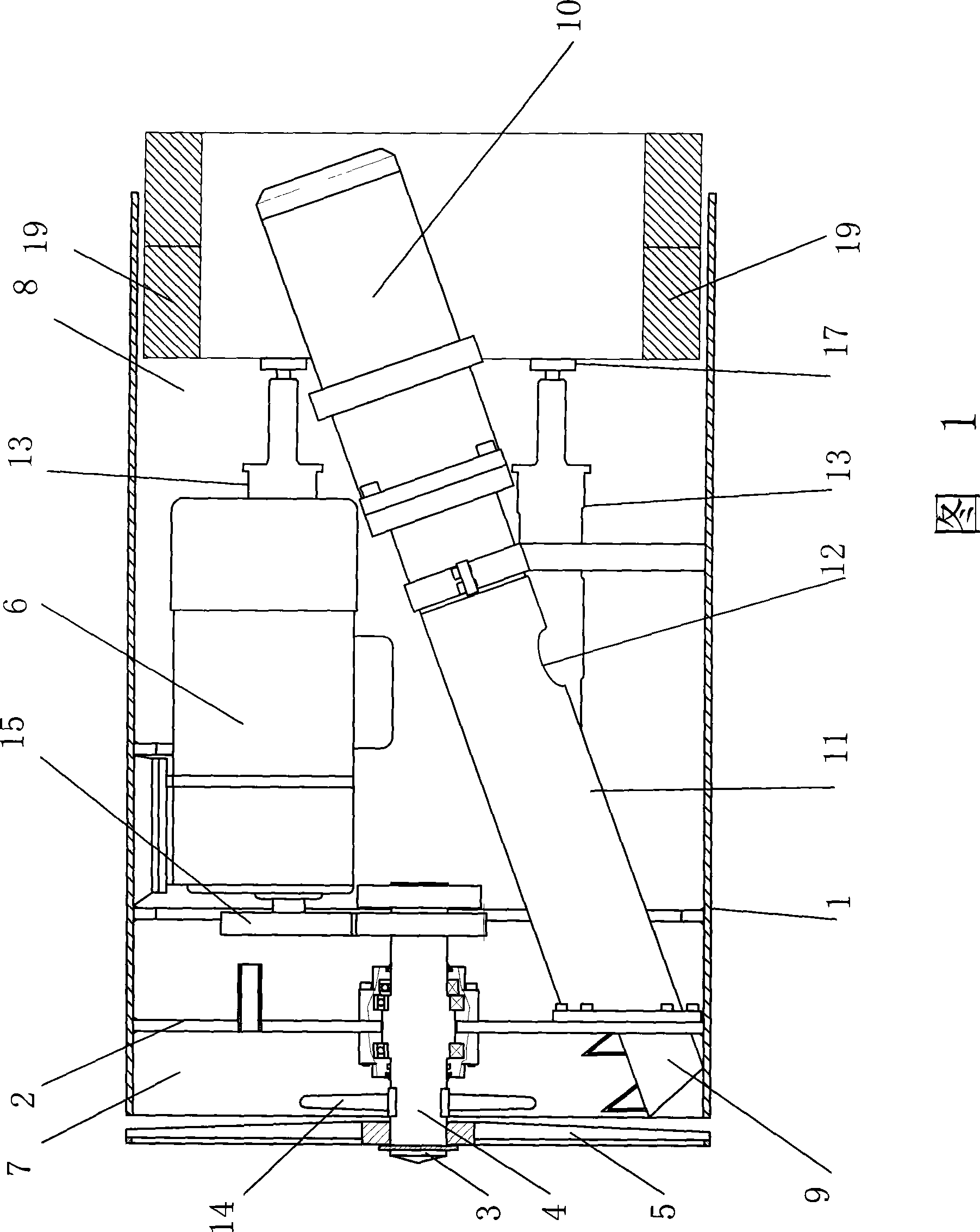

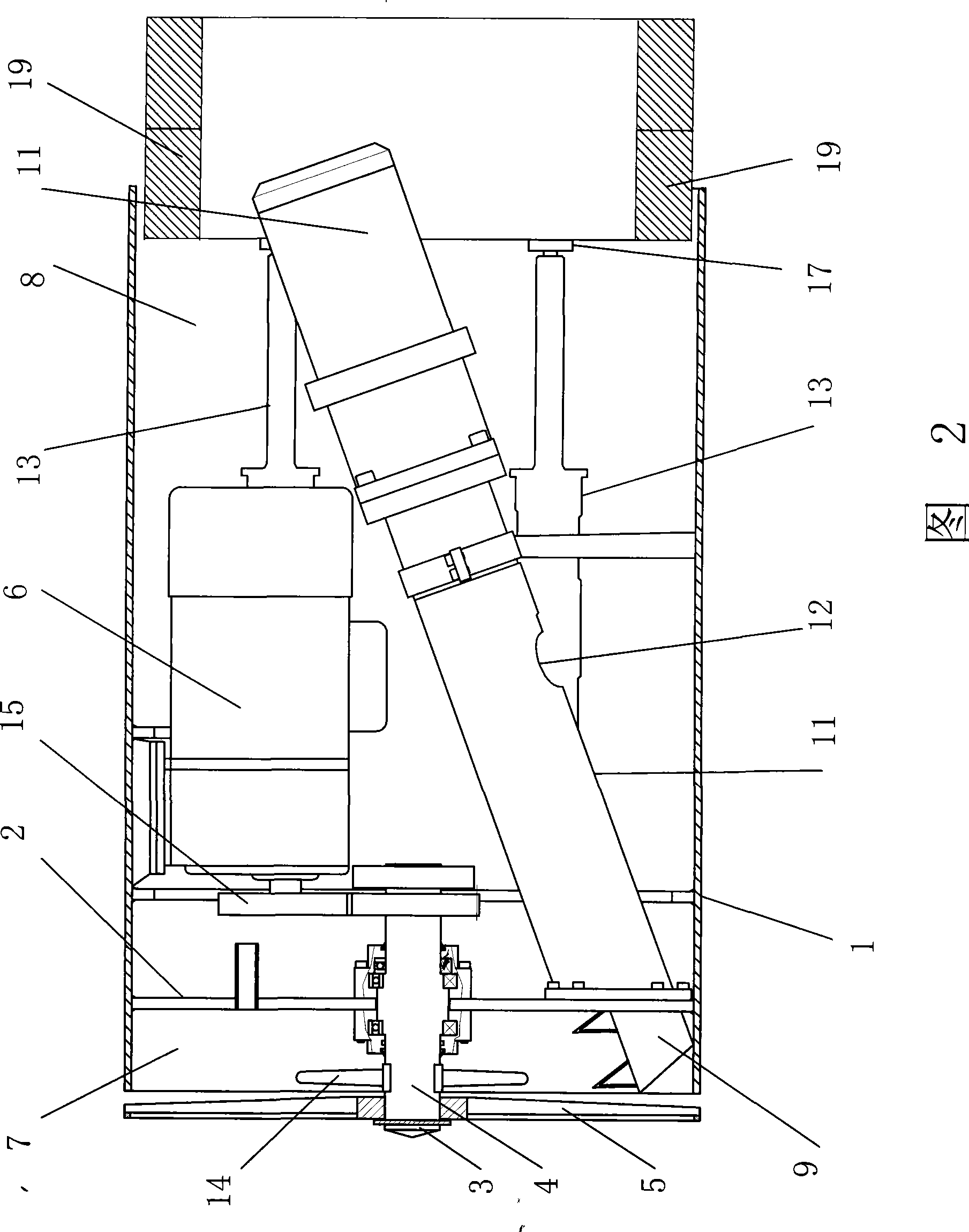

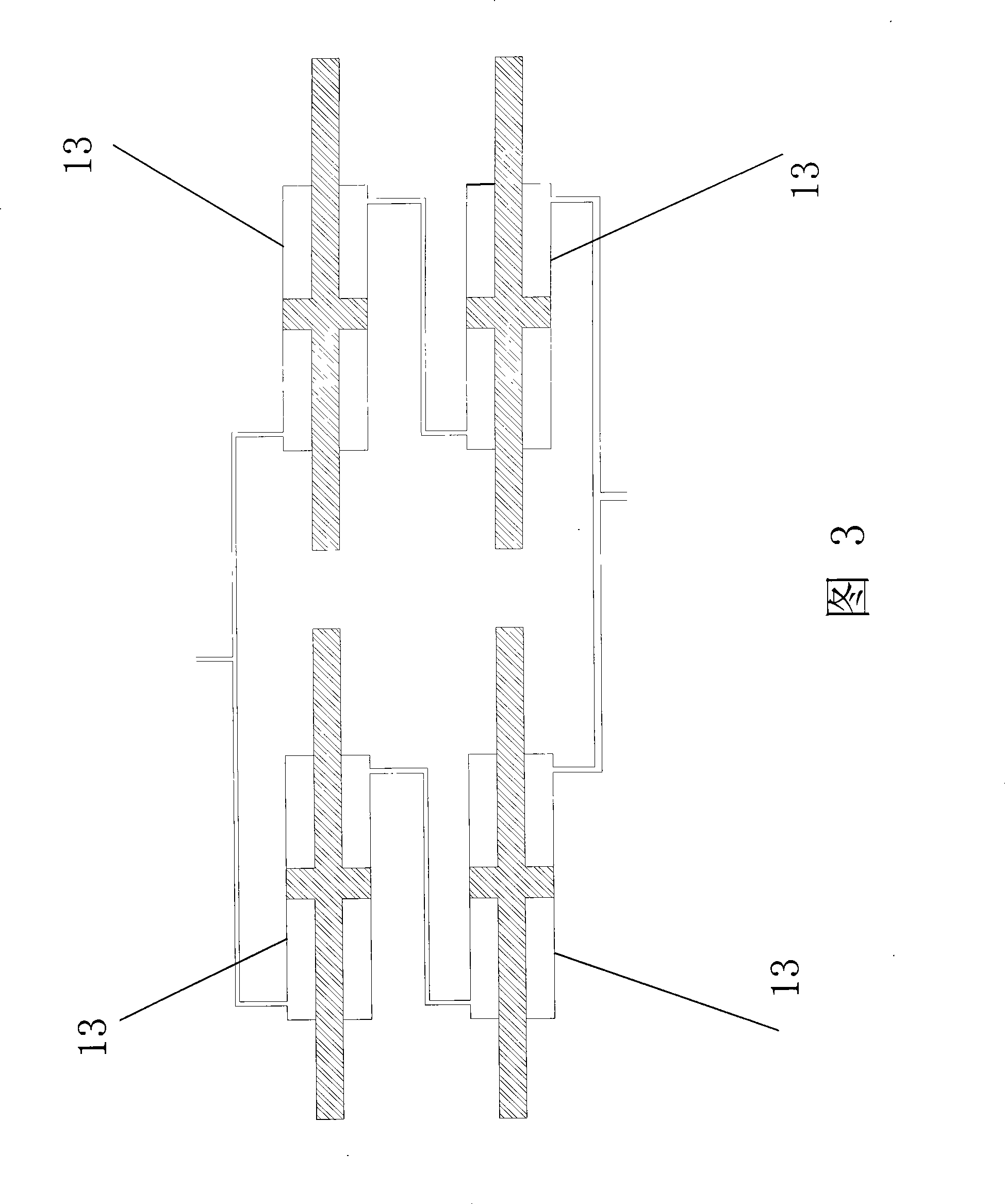

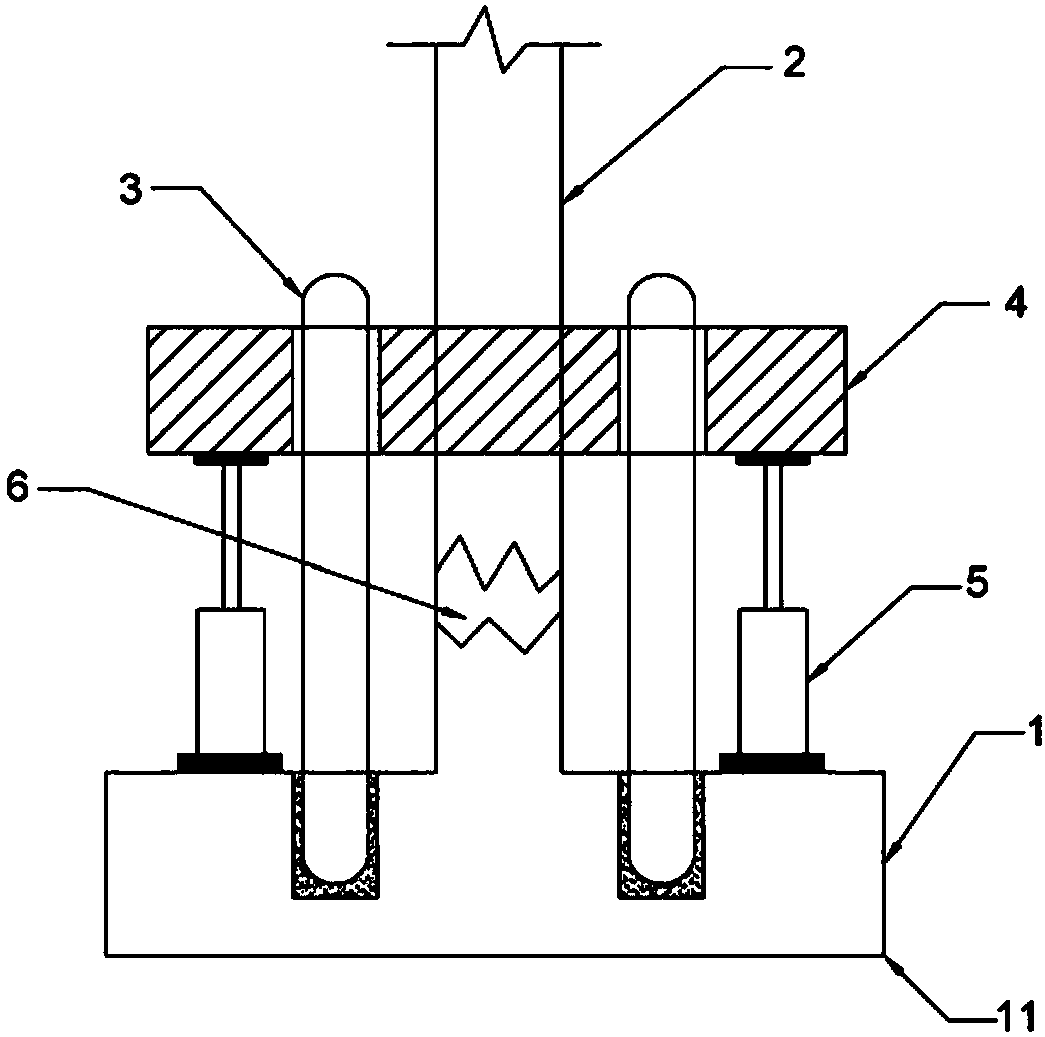

Small hydraulic opening and closing machine experimental device for teaching

PendingCN110675722AReduce weightReduce volumeCosmonautic condition simulationsEducational modelsElectrical controlEngineering

The invention discloses a small hydraulic opening and closing machine experimental device for teaching. The small hydraulic opening and closing machine experimental device comprises a general supportframe, a gate support frame, two connecting rods, a gate, two hydraulic rods, a fixed rod, a fixed block, a gate displacement feedback mechanism, a gate control group mechanism, an oil return tank, anoil pressure pump, a gate electrical control machine cabinet, a gate control cabinet, a bottom sill and a top sill, wherein the gate support frame is arranged on the general support frame; the two connecting rods are hinged to the gate support frame; the gate is connected with the connecting rods; one ends of the two hydraulic rods are hinged with the gate; the fixed rod is connected with the other ends of the hydraulic rods; the fixed block is hinged with the fixed rod and connected with the general support frame; the gate displacement feedback mechanism is connected with one sides of the hydraulic rods; the gate control group mechanism drives the two hydraulic rods to work; the oil return tank is arranged below the gate control group mechanism; the oil pressure pump is connected betweenthe oil return tank and the gate control group mechanism; and the bottom sill is arranged at the bottom end of the gate, and the top sill is arranged at the top end of the gate. The small hydraulic opening and closing machine experimental device has the advantages that the volume is small, the weight is light, the flow direction of the oil in a connecting pipeline can be conveniently observed, the device can be disassembled and assembled, the hydraulic grade of the hydraulic system is low, and teaching training of trainees can be facilitated.

Owner:SICHUAN HUANENG BAOXINGHE HYDROPOWER CO LTD

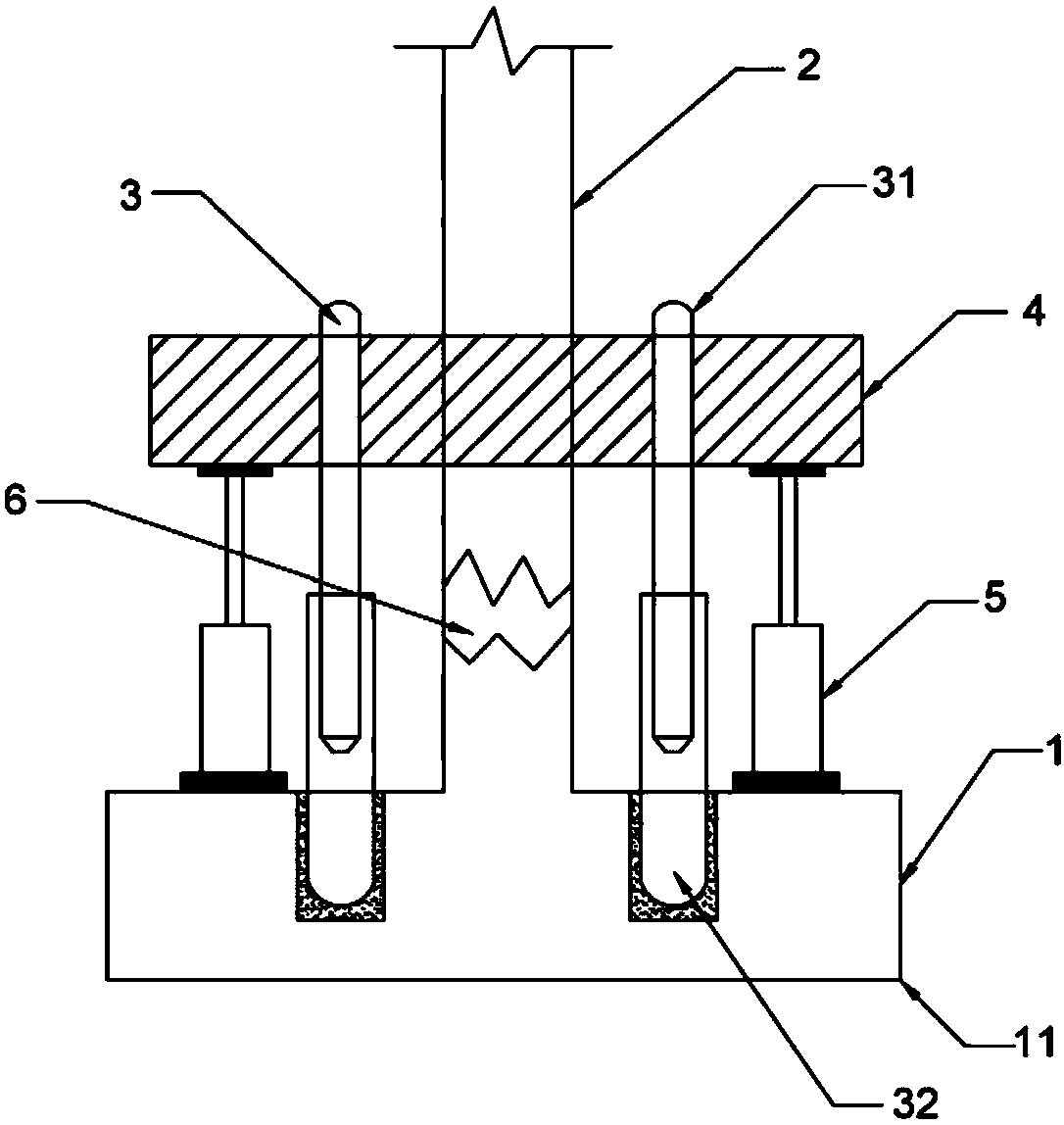

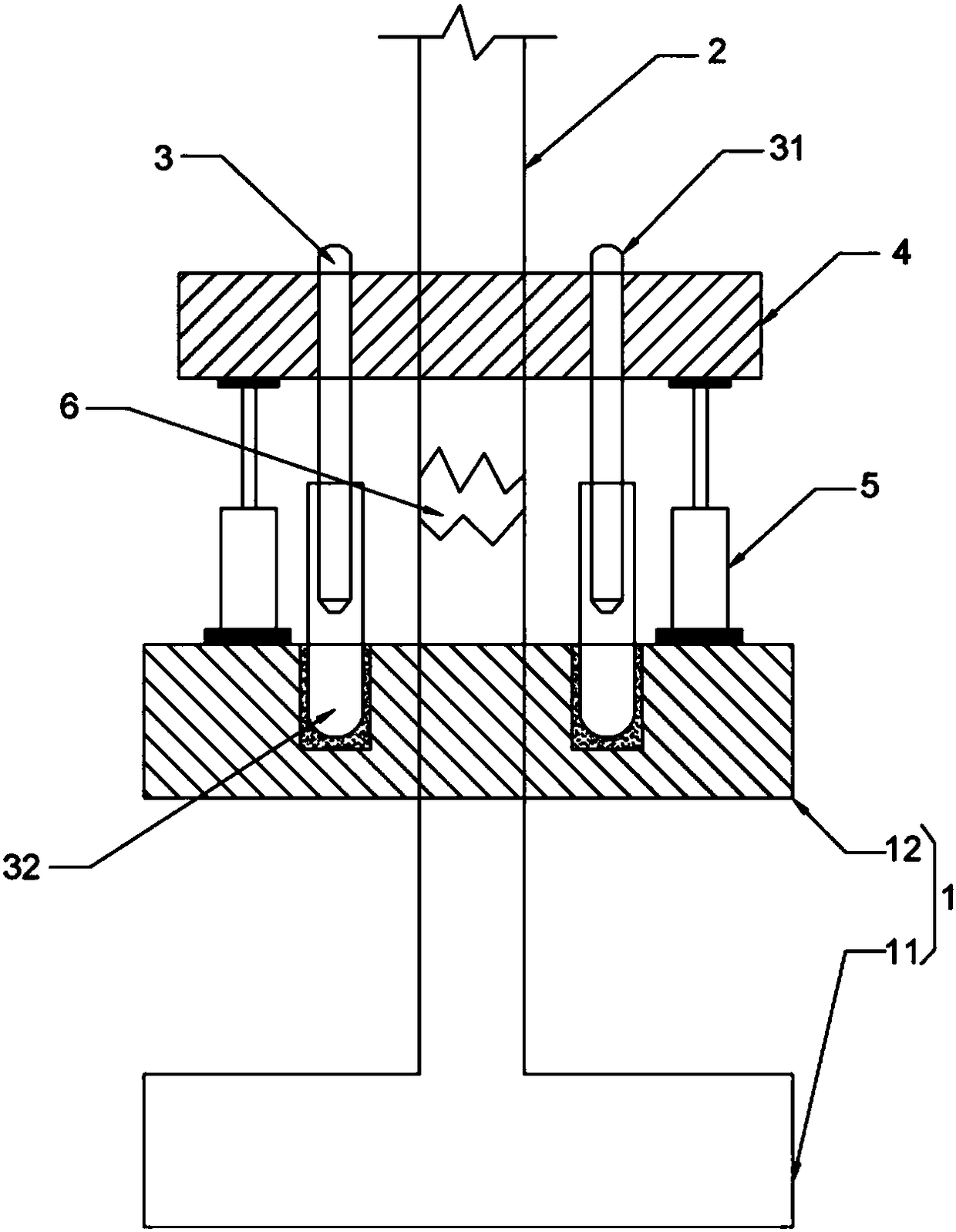

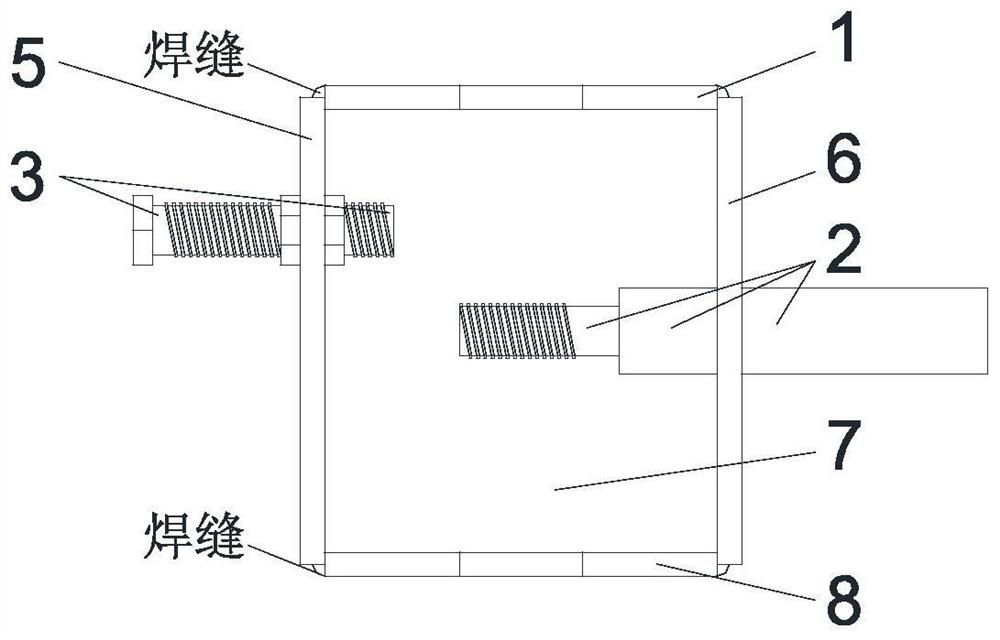

Deviation correcting structure and method of horizontal locking broken column

ActiveCN108412223ATo achieve the purpose of correctingAvoid tipping riskBuilding repairsFoundation engineeringEngineeringStructural engineering

The invention relates to the technical field of buildings, in particular to a deviation correcting structure and method of a horizontal locking broken column. The deviation correcting structure of thehorizontal locking broken column comprises a building foundation and a bearing column, and is characterized in that the bearing column is provided with a fracture, a column holding bearing tray is fixedly connected to the periphery of the bearing column, the fracture is located between the column holding bearing tray and the building foundation, at least two supporting piles are arranged on the periphery of the bearing column, one end of each supporting pile is embedded into the building foundation, the other end of each supporting pile penetrates through the column holding bearing tray, anda jacking device used for jacking the column holding bearing tray is further arranged under the column holding bearing tray. The structure is simple; in the jacking process, the risk of toppling caused by the influence of a horizontal load is avoided.

Owner:广东中青建筑科技有限公司

Deviation correcting device of belt conveyer and belt conveyer

ActiveCN106628937ATo achieve the purpose of correctingExtended service lifeConveyorsRollersEngineeringStructural engineering

Owner:SHANDONG IRON & STEEL CO LTD

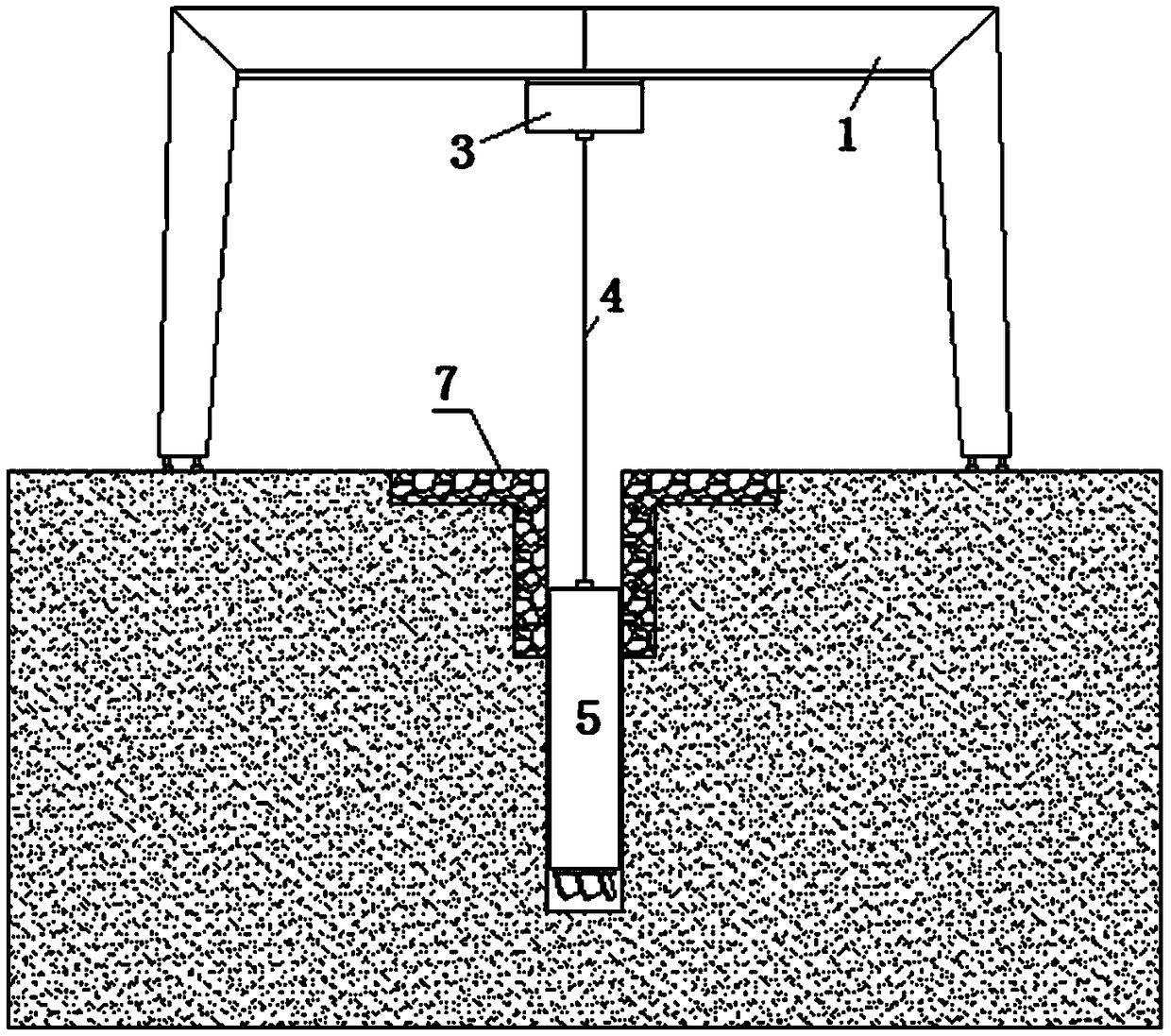

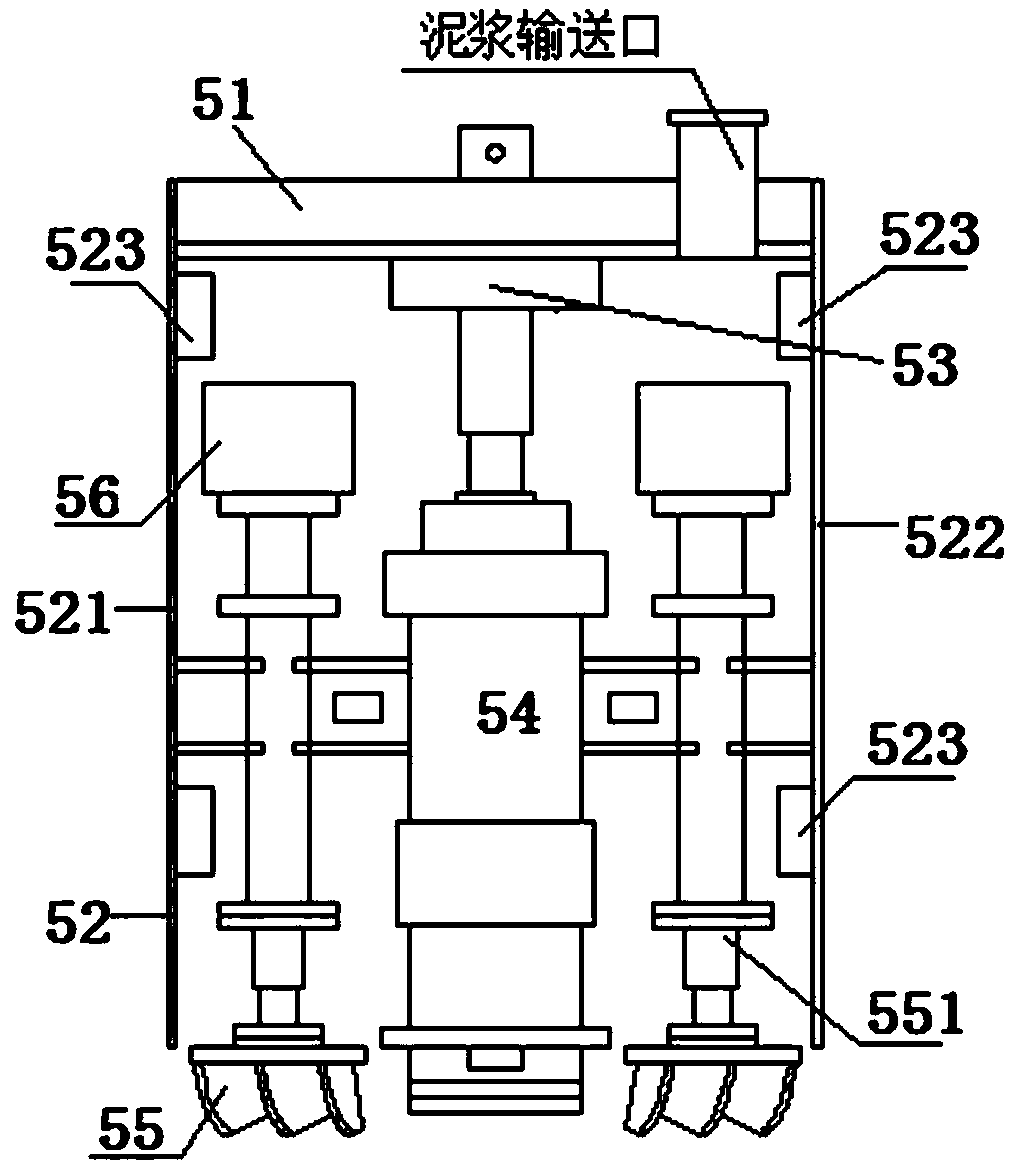

Method for constructing underground continuous wall by using cutter-suction head

The invention discloses a method for constructing an underground continuous wall by using a cutter-suction head. The method for constructing the underground continuous wall by using the cutter-suctionhead is characterized in that a plurality of travelling cranes, a mud-water separator and tracks are included, wherein the tracks are arranged on the lower surfaces of the travelling cranes, and travelling crane power devices arranged on the tracks are connected with the cutter-suction head through wire ropes; the cutter-suction head comprises a transverse beam, a rectangular cylinder arranged atupper and lower end openings of the transverse beam, a hydraulic device connected to the middle part of the lower surface of the transverse beam, a mud pump connected with a connecting rod of the hydraulic device and two reamers arranged on both sides of the mud pump; and the mud pump is fixedly connected with connecting shafts of the two reamers correspondingly, and the two connecting shafts areconnected with two reamer motors correspondingly. The method for constructing the underground continuous wall by using the cutter-suction head has the characteristic that the underground continuous wall construction can be carried out on a narrow site.

Owner:GEOTECHN TECH

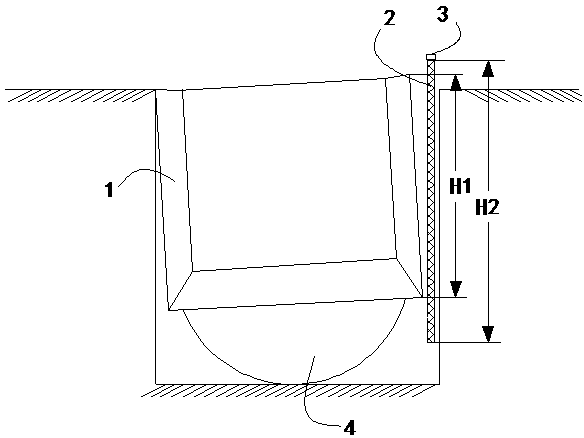

Simple efficient open caisson deviation rectifying method

InactiveCN110144921ATo achieve the purpose of correctingEliminate or reduce frontal dragCaissonsStructural engineeringEngineering

The invention discloses a simple efficient open caisson deviation rectifying method. The simple efficient open caisson deviation rectifying method is characterized by comprising the following steps that 1, a deviation rectifying tool is selected, wherein a stretching steel plate pile of the corresponding length is selected according to the depth of an open caisson; 2, locality deviation excavationis carried out, wherein for the side, which cannot sink down, of the wall of the open caisson, cubic meter of earth on the bottom of the wall of the open caisson is excavated; and 3, deviation is rectified, wherein for the side, which cannot sink down, of the open caisson, the stretching steel plate pile sequentially carries out inserting and pulling on the outer side of the wall of the open caisson. The depth of the open caisson is set to be H1, the length of the stretching steel plate pile is set to be H2, and the length H2 of the stretching steel plate pile is larger than or equal to the depth H1 of the open caisson. According to the simple efficient open caisson deviation rectifying method, the technology of the deviation rectifying method is simple, meanwhile, the deviation rectifying effect is good in practicality, and the method is efficient.

Owner:GUANGDONG TECHN COLLEGE OF WATER RESOURCES & ELECTRIC ENG

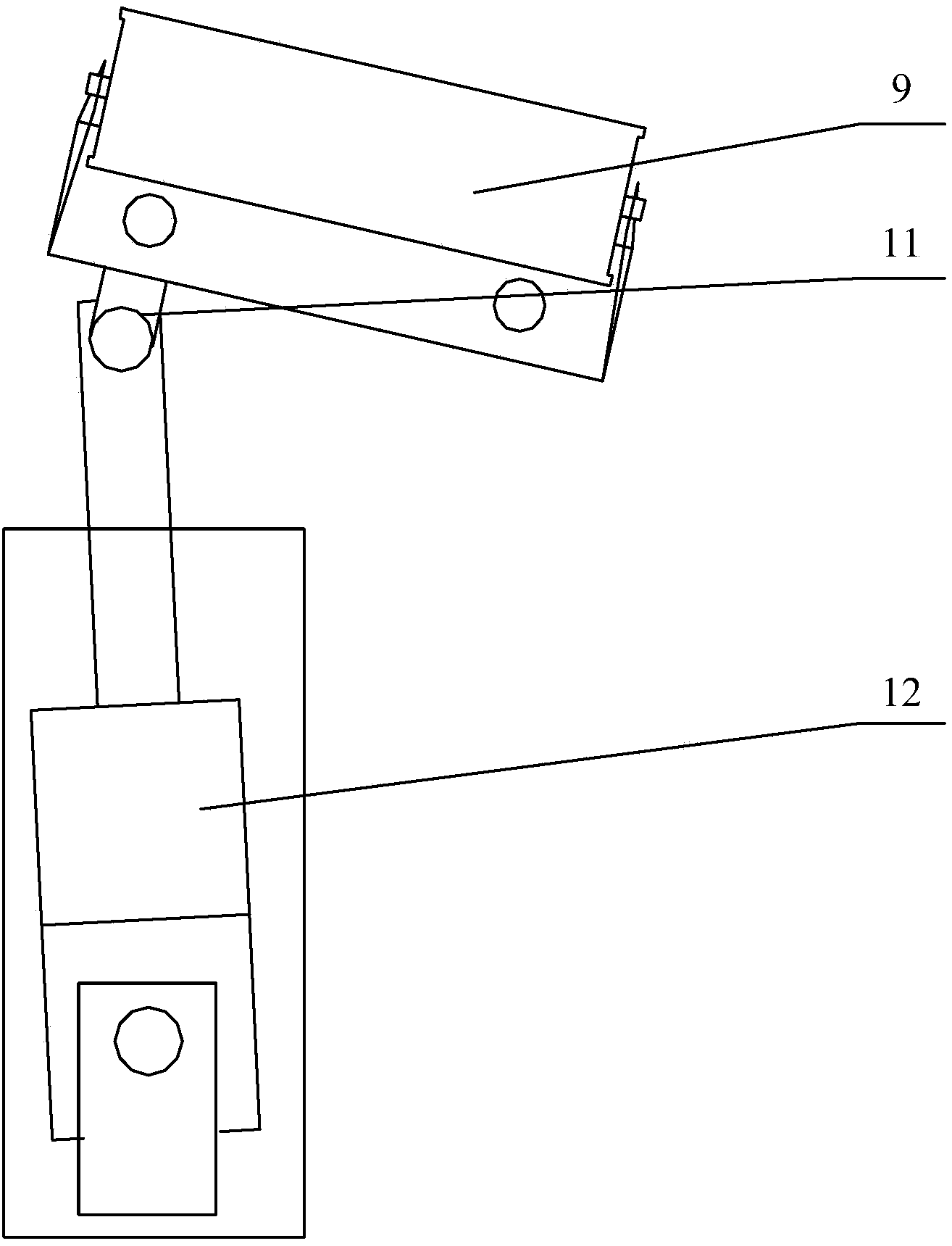

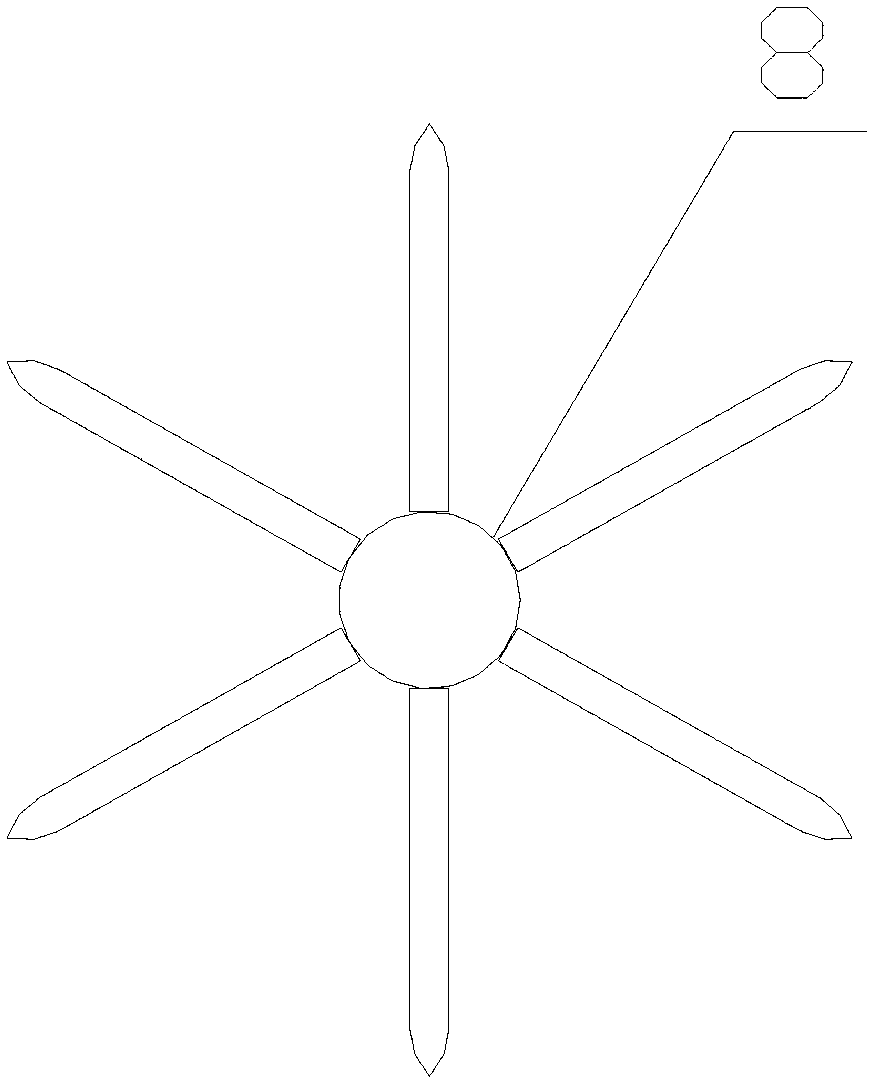

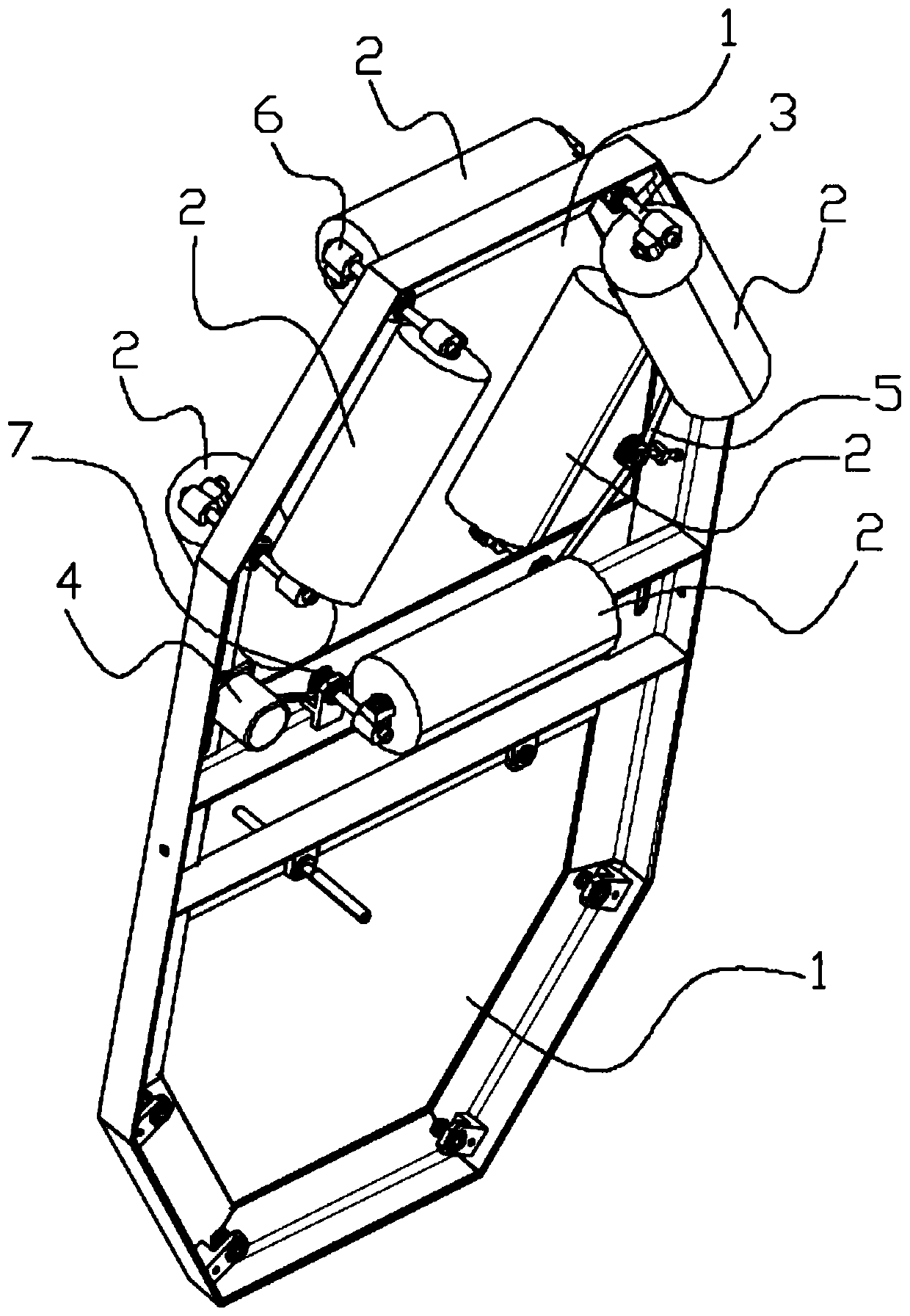

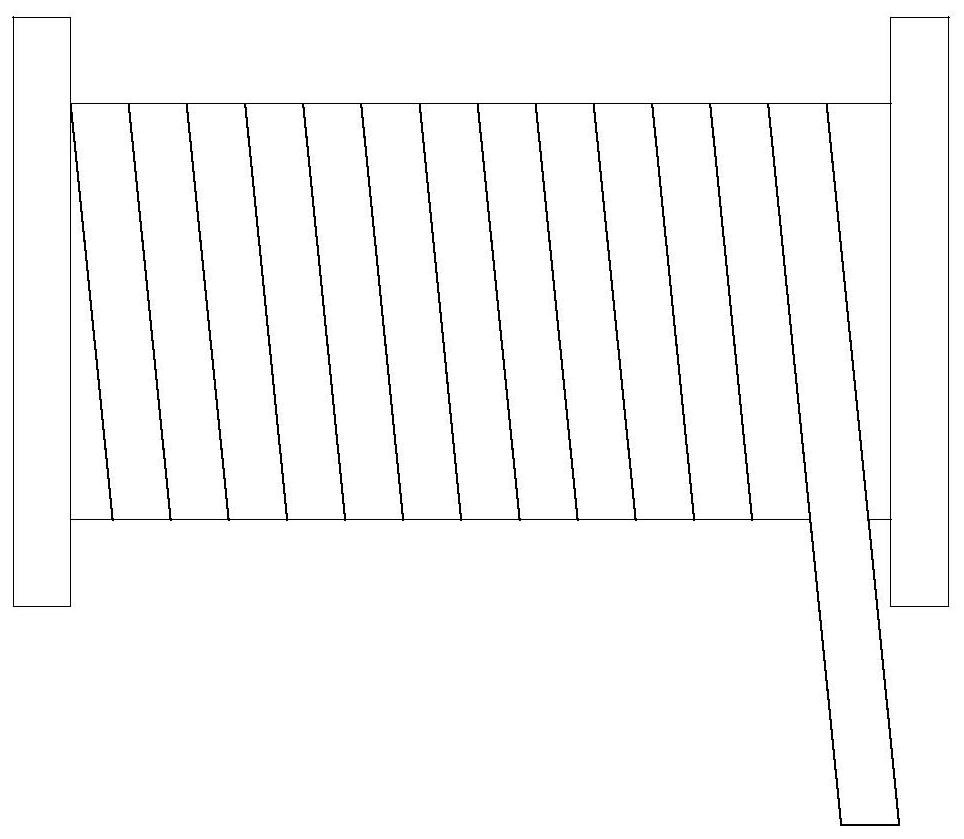

Rectifying and expanding roller for flexile fabric

ActiveCN105525474AAccurate locationAchieve the effect of openingStretchingTextile treatment carriersEngineeringFully automatic

The invention provides a rectifying and expanding roller for flexile fabric and belongs to the field of printing and dyeing textile equipment. The rectifying and expanding roller comprises a roller body, a left rolling wheel and a right rolling wheel, wherein the left rolling wheel and the right rolling wheel are oppositely connected onto the roller body and arranged obliquely. The rectifying and expanding roller further comprises an inclination angle adjusting device used for adjusting inclination angles of the left rolling wheel and the right rolling wheel, and the inclination angle adjusting device is arranged on the roller body. The rectifying and expanding roller for the flexile fabric can expand and rectify the flexile fabric, integrates expanding and rectifying functions, is simple in structure and convenient to operate, improves the rectifying effect and efficiency greatly and is fully automatic in the whole expanding and rectifying process.

Owner:TONGZHOU XINGCHEN MACHINERY

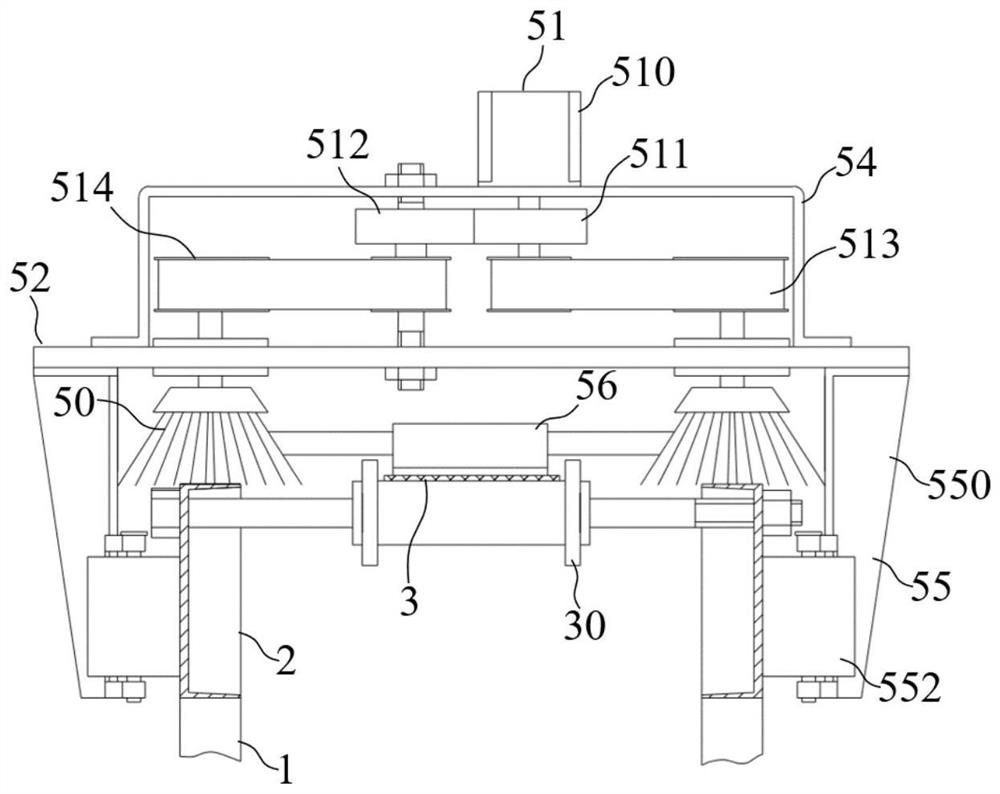

Coiled material correcting and winding mechanism, and winding method

InactiveCN111252601ASmooth edgesTo achieve the purpose of correctingWebs handlingExecution unitControl theory

The invention provides a coiled material correcting and winding mechanism, and a winding method. Through real-time detection of the edge position of coiled materials located between a material guidingwheel and a coiled material shaft, and output of control commands to a corrective execution unit according to the edge position of the coiled materials, the position of the coiled materials on the material guiding wheel is regulated in real time; and the purpose of correction is achieved, so that the edge of a material coil is kept flat after the coiled materials are wound on a reel. The correcting and winding mechanism is simple in structure, low in cost, high in reliability and convenient in maintenance and servicing, and the enterprise revenue can be improved; and meanwhile, the overall size is smaller, and the correcting and winding mechanism is easy to install and use in a smaller space.

Owner:昆山捷诚安智能自动化有限公司

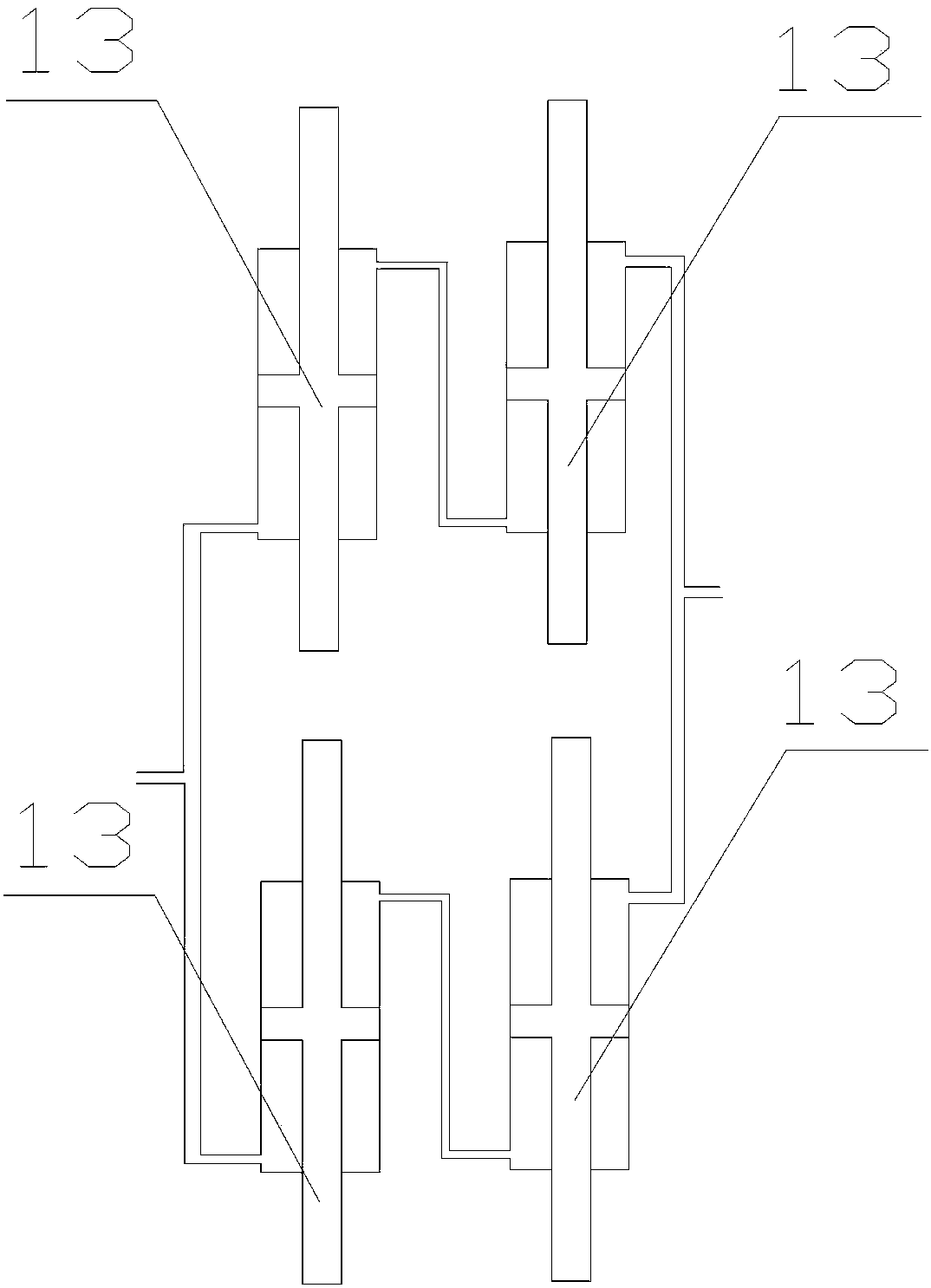

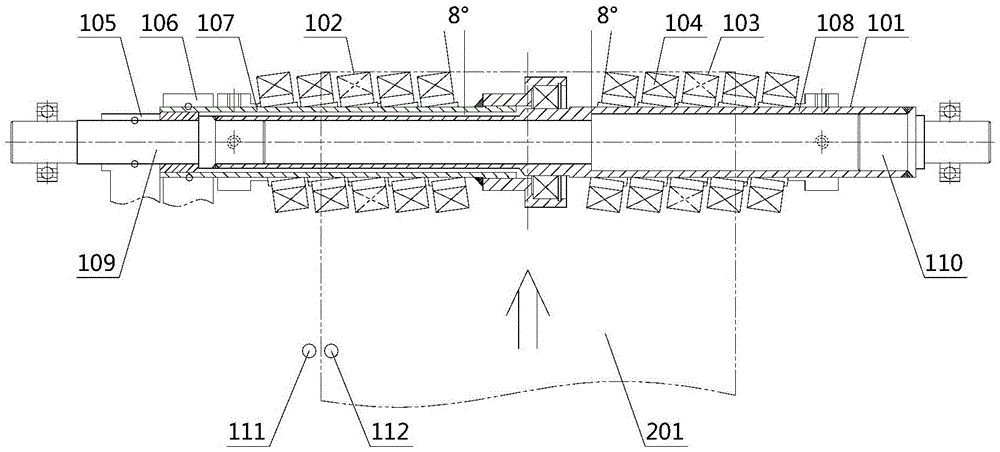

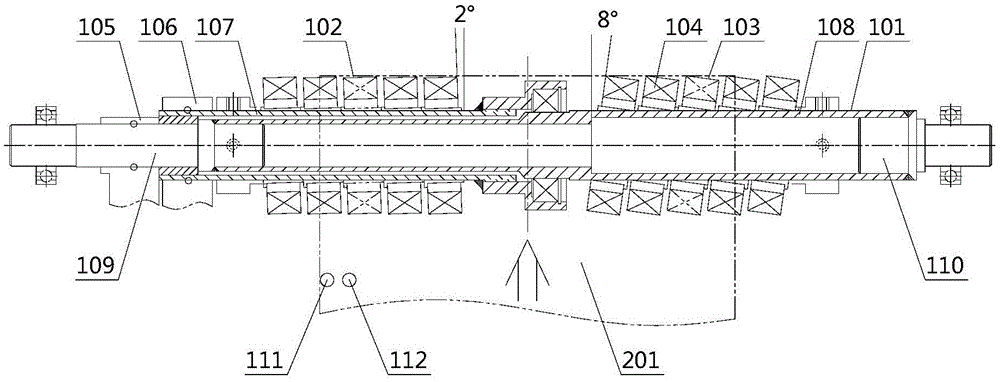

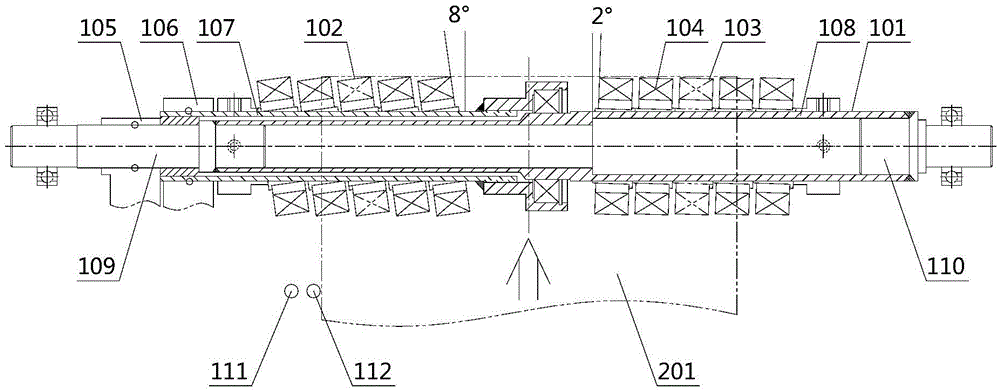

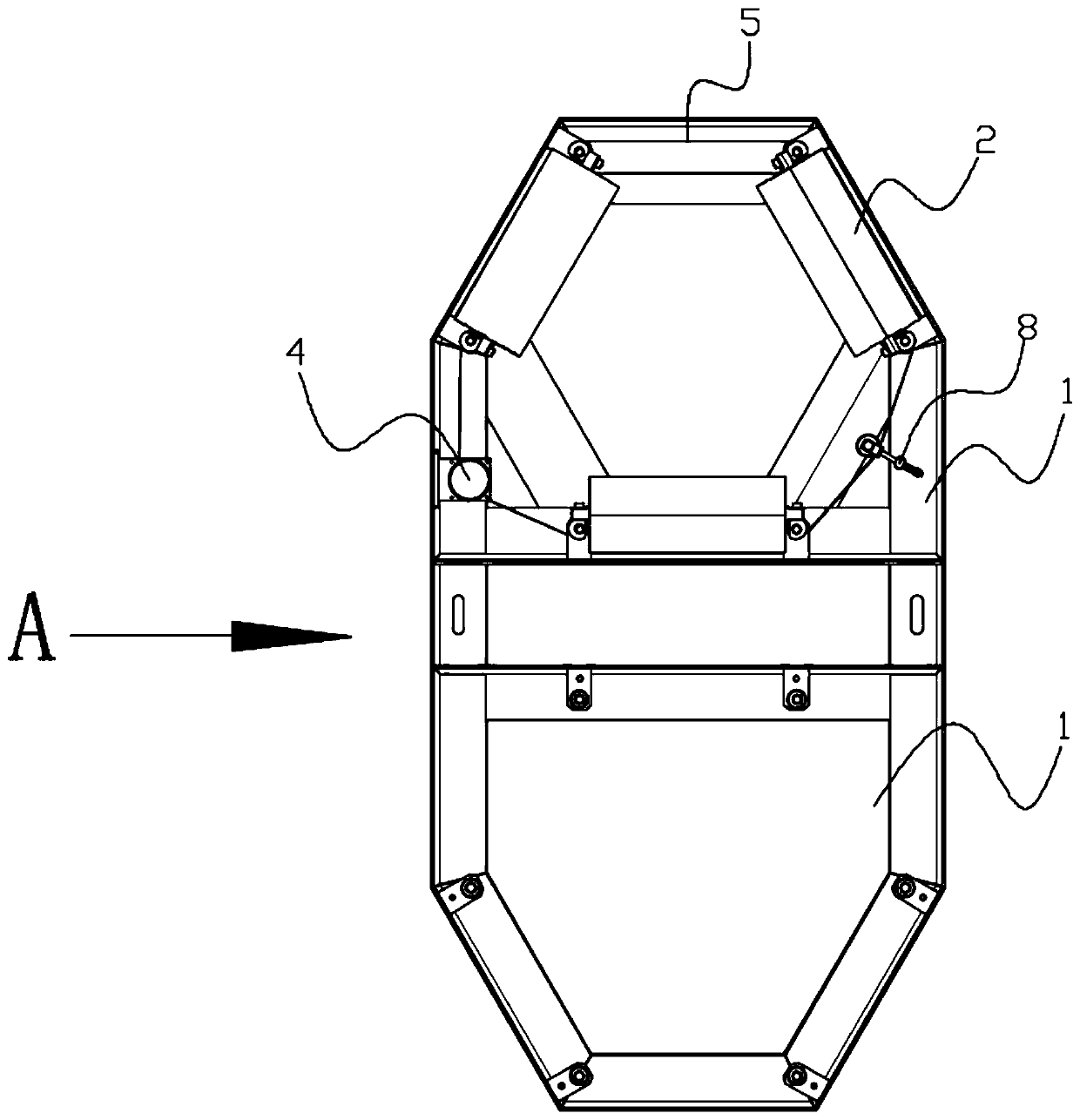

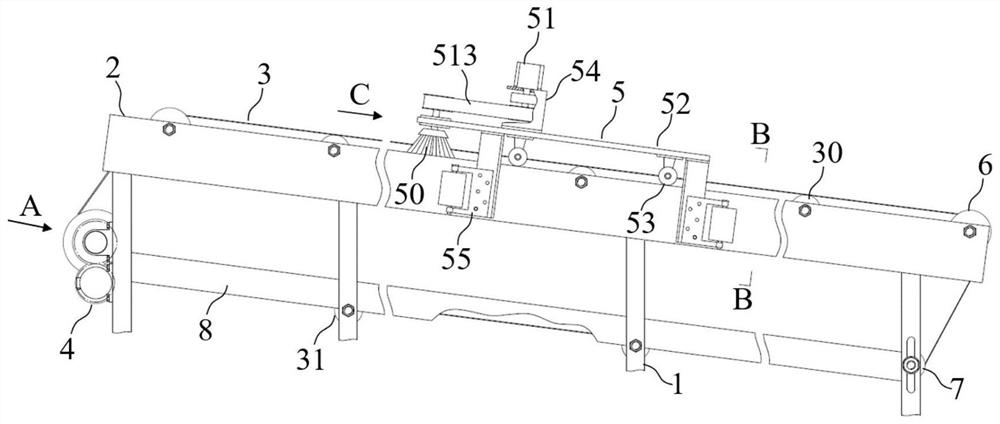

Deviation rectifying device of tubular belt conveyor

InactiveCN110817255ADoes not affect upstream and downstream processesGuaranteed production efficiencyConveyorsRollersElectric machineryEngineering

The invention discloses a deviation rectifying device of a tubular belt conveyor, and belongs to the technical field of tubular belt conveyors. The deviation rectifying device comprises two integrallyformed shuttle frames, wherein the two shuttle frames are arranged symmetrically up and down; each shuttle frame is of a polygonal structure; one side of each side of each shuttle frame is provided with a carrier roller; the carrier rollers on the adjacent sides of each shuttle frame are respectively arranged on the two sides of the shuttle frame; front and back tooth screw rods penetrate throughthe connection positions of the adjacent sides of each shuttle frame; teeth, positioned on the same side of the shuttle frame, of the adjacent front and back tooth screw rods are opposite; the two ends of each front and back tooth screw rod are both in threaded connection with nuts; the two ends of each carrier roller are respectively and fixedly connected with the two nuts adjacent to the carrier roller; and each shuttle frame is provided with a positive and negative motor which is in synchronous transmission connection with every front and back tooth screw rod. According to the deviation rectifying device of the tubular belt conveyor, the deviation rectifying operation can be carried out without stopping the tubular belt conveyor, so that the upstream and downstream processes are not affected, the production efficiency is ensured, and the deviation rectifying is high.

Owner:欧义军

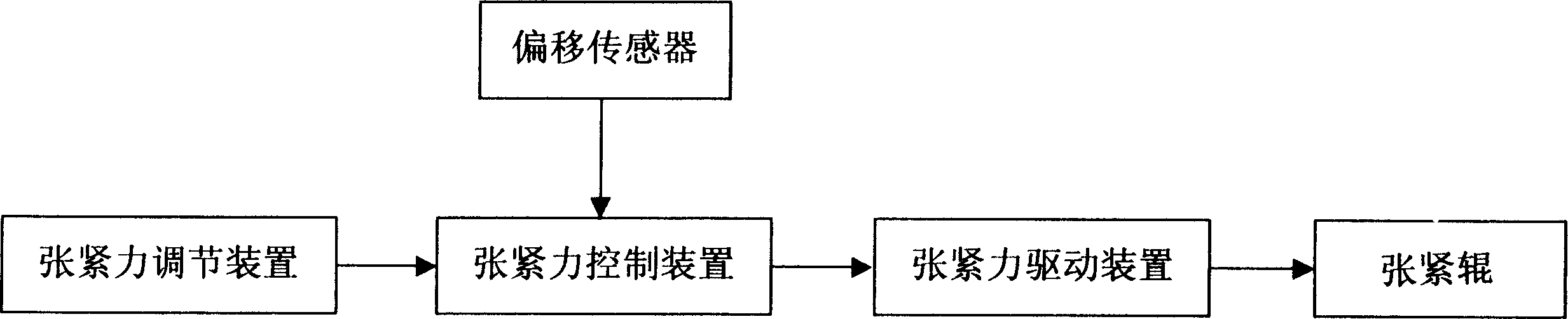

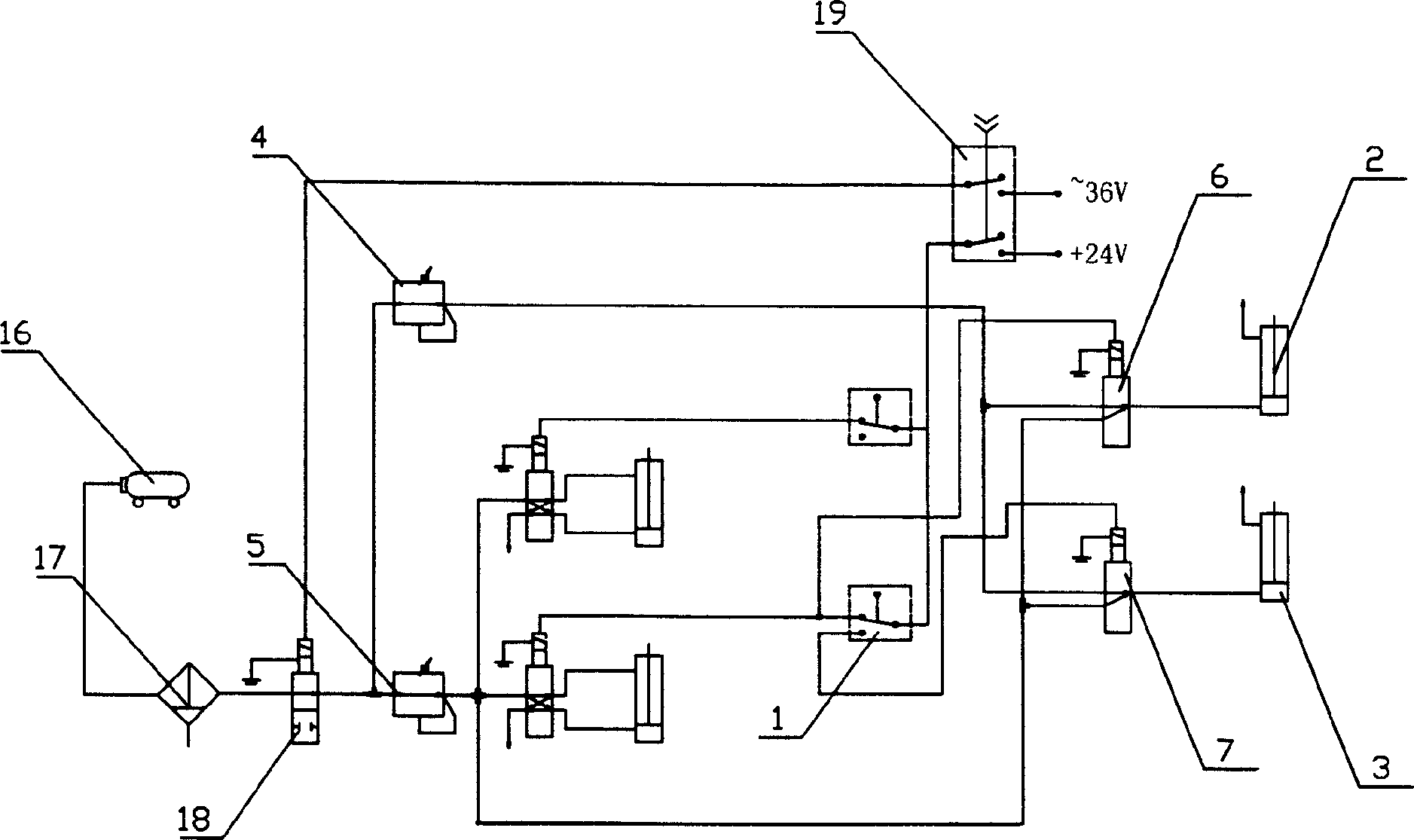

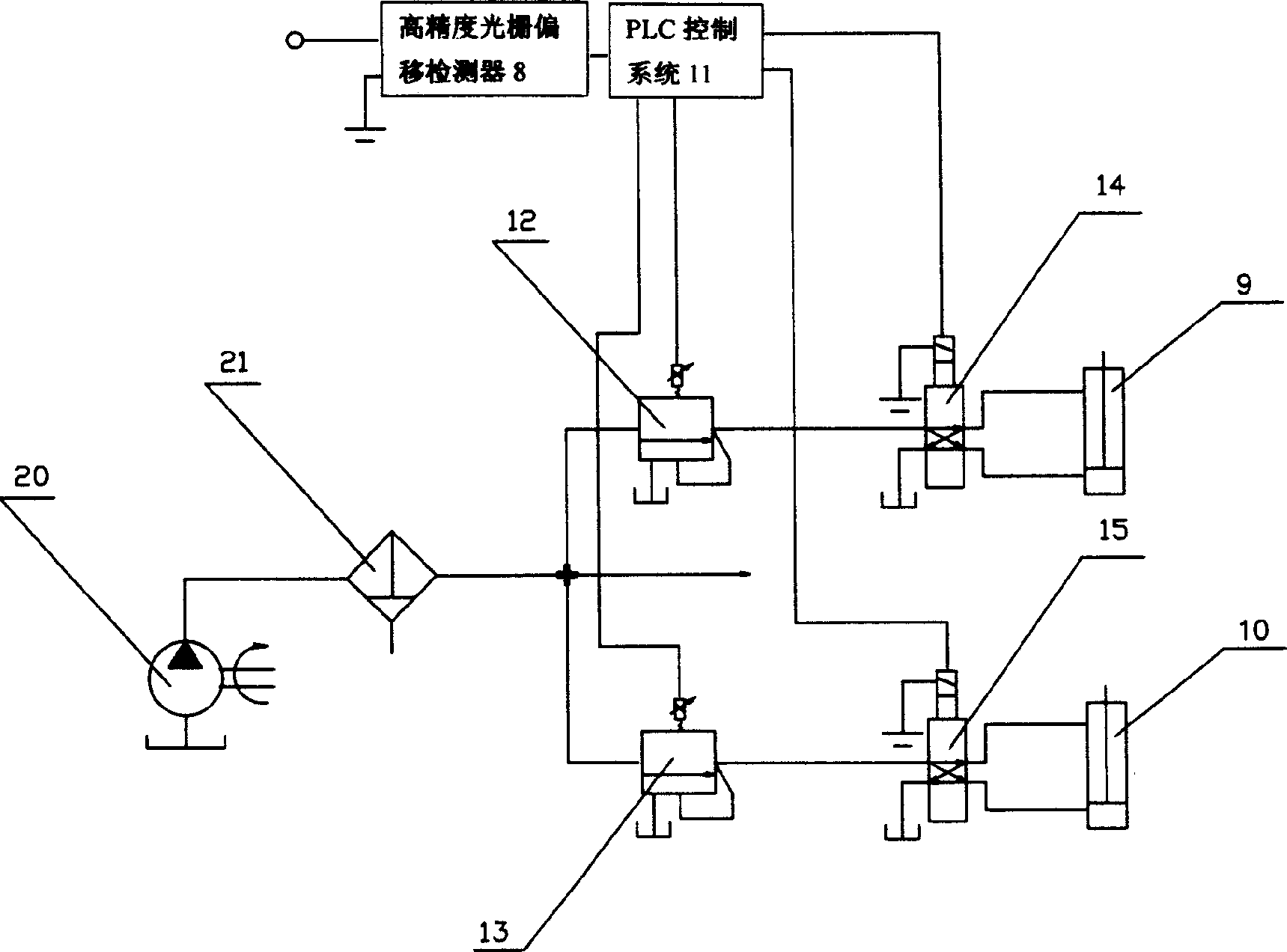

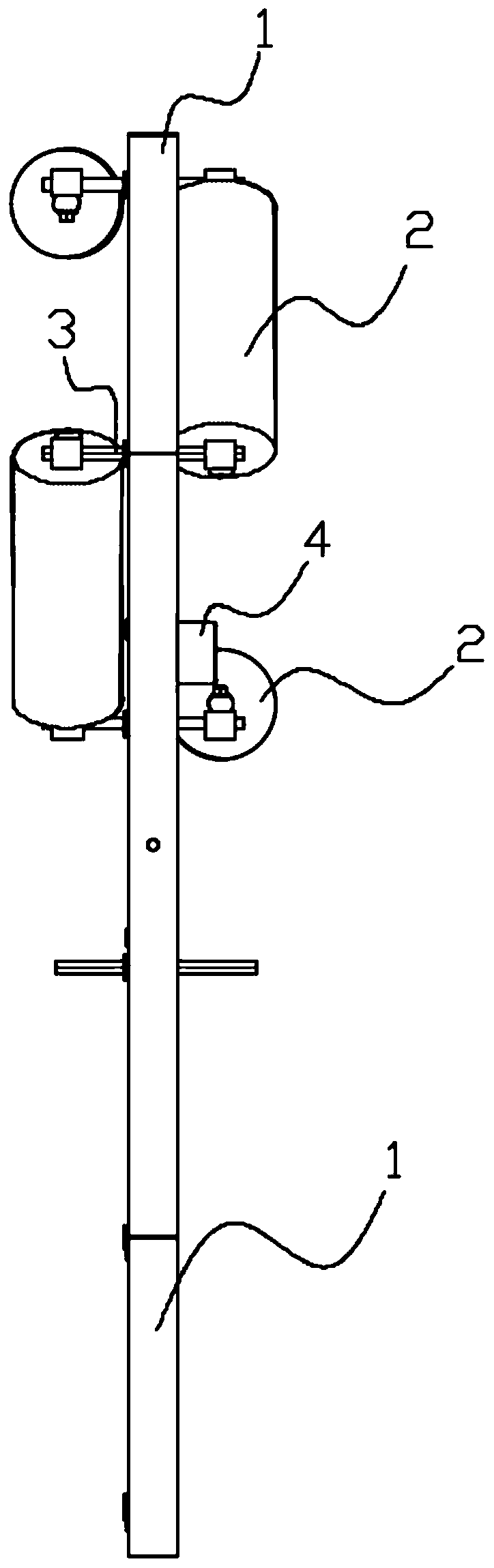

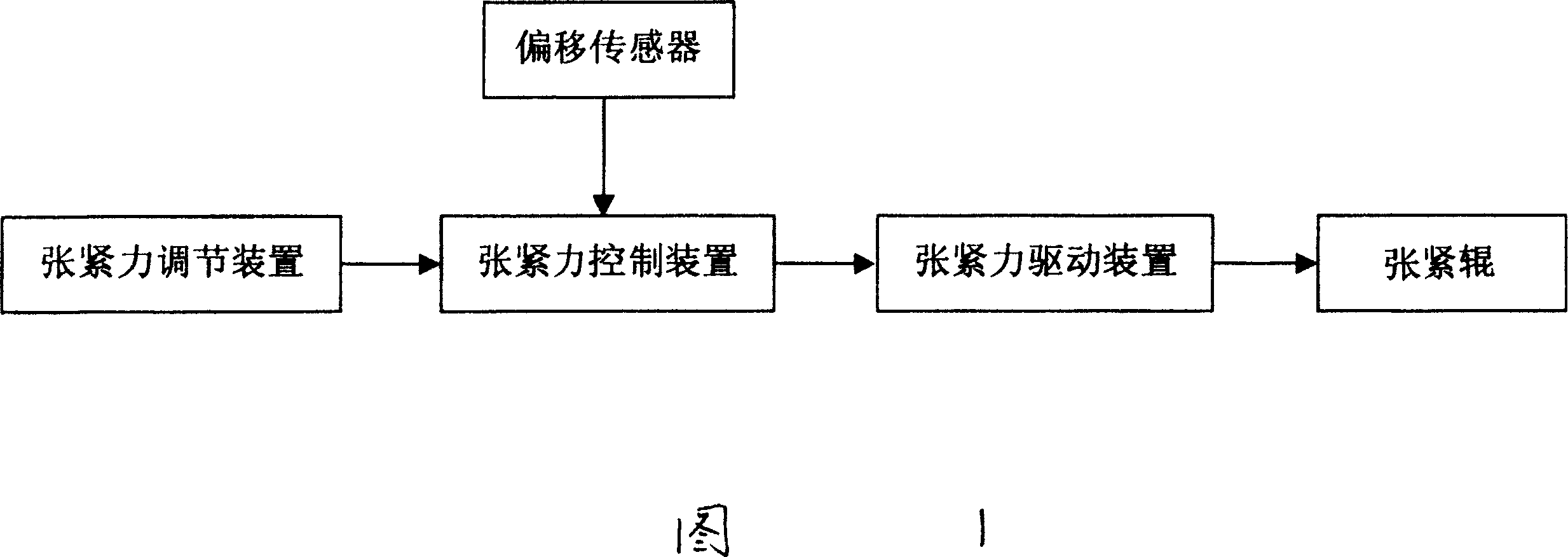

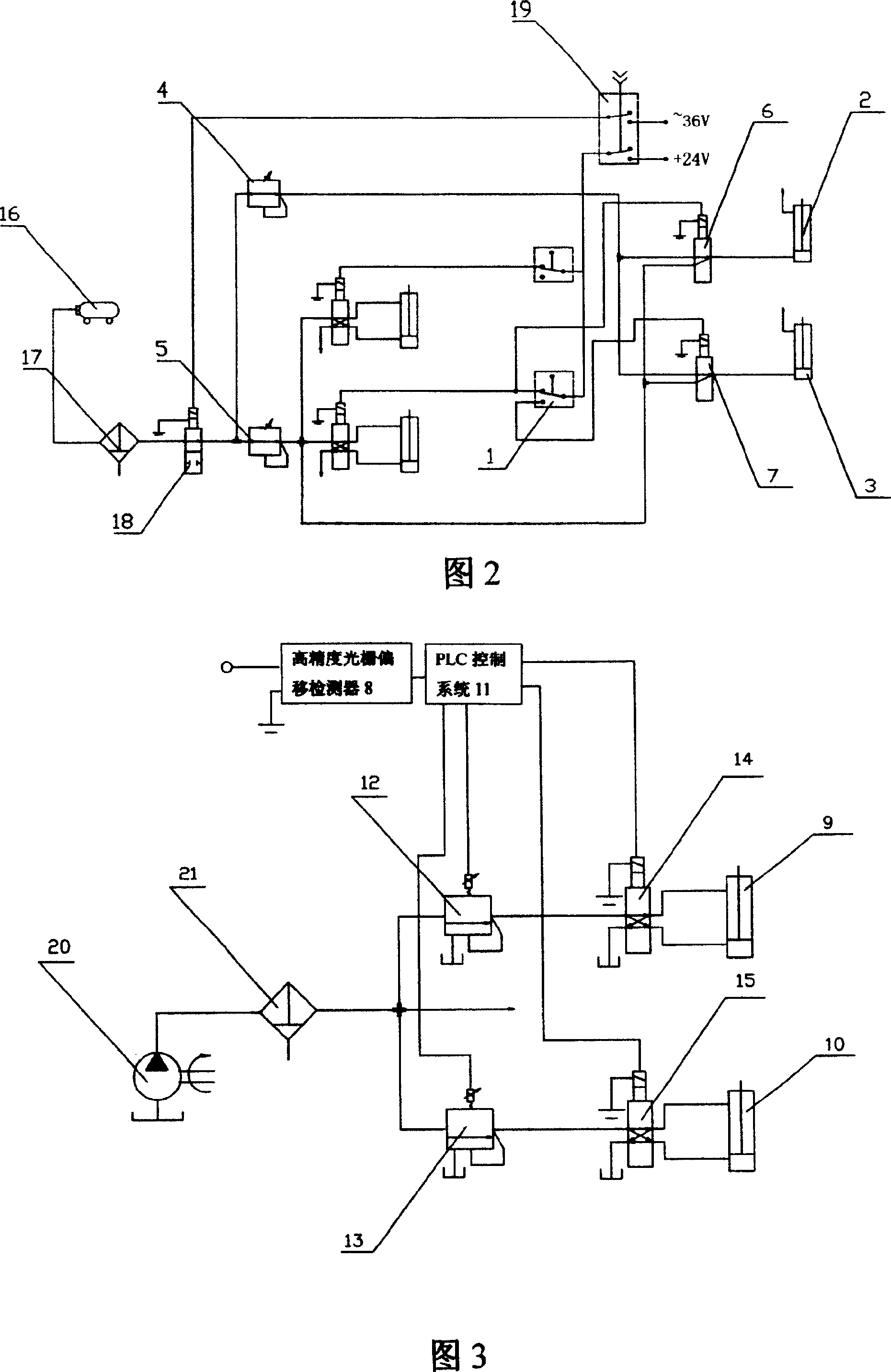

Belt-shape moving body tension differential adjusting and correction method and device therefor

InactiveCN100366517CAdjust the tensioning pressure in timeTo achieve the purpose of correctingWebs handlingState of artBand shape

Owner:大连经济技术开发区排水管理有限公司

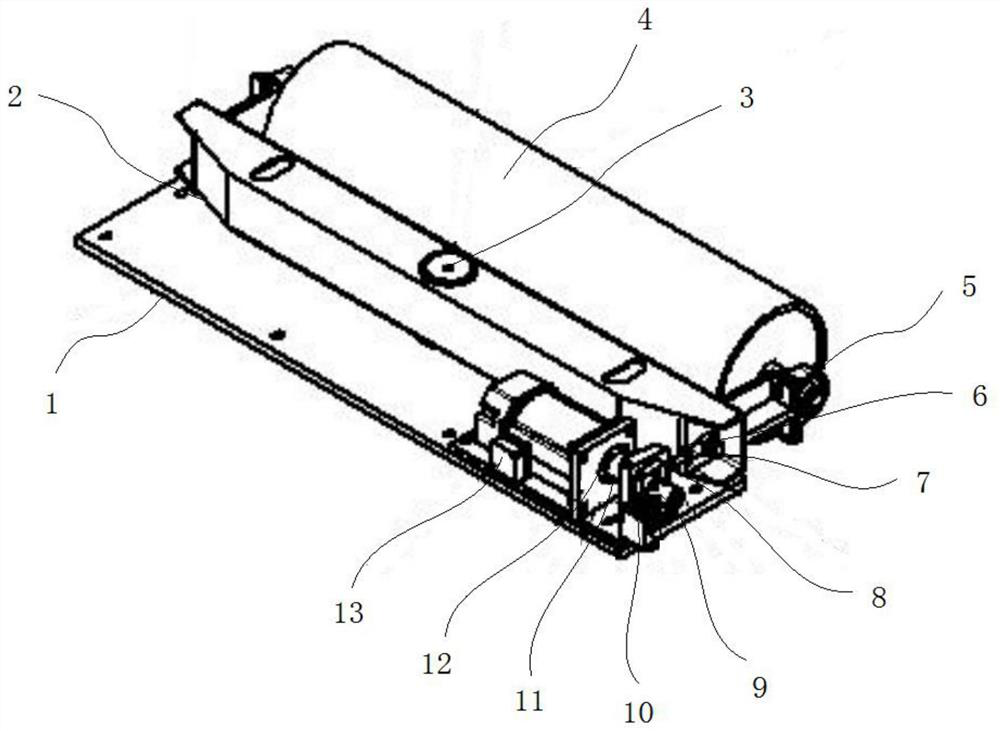

A mesh belt automatic deviation correction device

ActiveCN112478602BGuaranteed normal operationTo achieve the purpose of correctingConveyorsControl devices for conveyorsRotational axisElectric machine

The invention provides an automatic deviation correction device for a mesh belt. The mesh belt automatic deviation correction device comprises: a deviation correction base plate; a deviation correction installation plate, the deviation correction installation plate is arranged on the top of the deviation correction base plate, and a rotating shaft is arranged on the deviation correction installation plate; a deviation correction wheel is arranged on the top of the deviation correction base plate On one side, a bearing with seat is provided on the axis of the correction wheel, and a connecting bearing is provided on one side of the bearing with seat. The mesh belt automatic deviation correction device provided by the present invention drives the motor to rotate, drives the crankshaft to rotate, and moves the connecting block in linkage, pulls the connecting guide rod and the connecting bearing to make a linear motion, and at the same time drives the deviation correcting installation plate to rotate a certain angle around the rotation axis, and feeds back to the photoelectric switch. When the photoelectric switch has no signal, the mesh belt deviation correction adjustment is completed, and the purpose of mesh belt deviation correction is finally achieved. It can realize the online operation detection of the mesh belt, real-time deviation correction, eliminate manual intervention, ensure long-term reliable operation of the equipment, and greatly improve the operation efficiency of the equipment.

Owner:HENGLI ELETEK

A kind of medicine chip ironing and straightening mechanism and ironing and straightening process thereof

ActiveCN112716694BGood heating contactImprove cooling effectIroning apparatusSanitary towelsAssembly lineIndustrial engineering

The invention relates to the field of disposable sanitary products, in particular to a medicine chip ironing and straightening mechanism, comprising a frame, an unwinding device arranged on the frame according to an assembly line, a first tensioning device, an ironing and straightening device, a traction device, a second tensioning device The ironing and straightening device includes an ironing and straightening bracket and a heating and smoothing roller rotatably arranged on the ironing and straightening bracket. The heating temperature is 100-150℃. The invention solves the technical problem that the existing drug core is twisted and deformed when it is unrolled again after being formed and rolled, and the technical problem of great defects in the production process of sanitary products. An ironing process based on a medicine chip ironing mechanism.

Owner:FUJIAN HENGAN HLDG CO LTD +2

Lower clamp

The invention discloses a lower clamp. The lower clamp comprises a base and a clamp mechanism; a connecting hole is formed in the base; the clamp mechanism comprises a connecting shaft and a power device; one end of the connecting shaft is connected with the power device, and the other end is connected with a support ring at the tail of a rocket; and one part of the power device and one part of the connecting shaft are arranged in the connecting hole and are connected with the base in a shaft penetrating mode. The lower clamp has the technical effects of being simple in structure and capable of fixing and adjusting the position of the rocket.

Owner:北京中科宇航技术有限公司

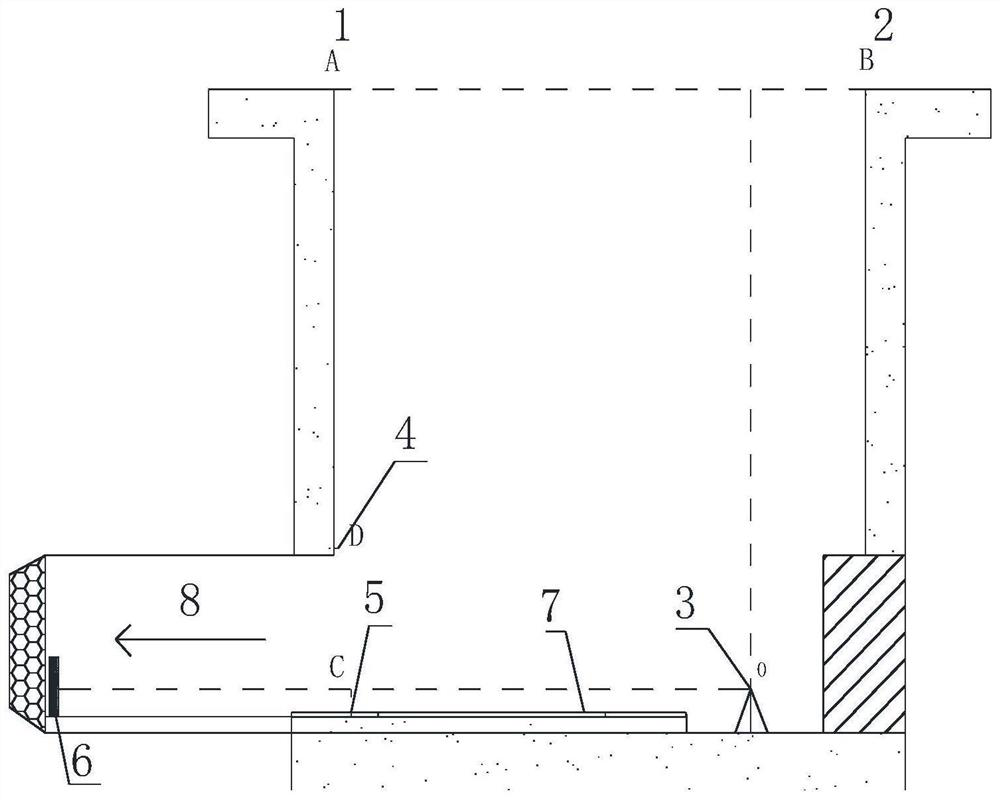

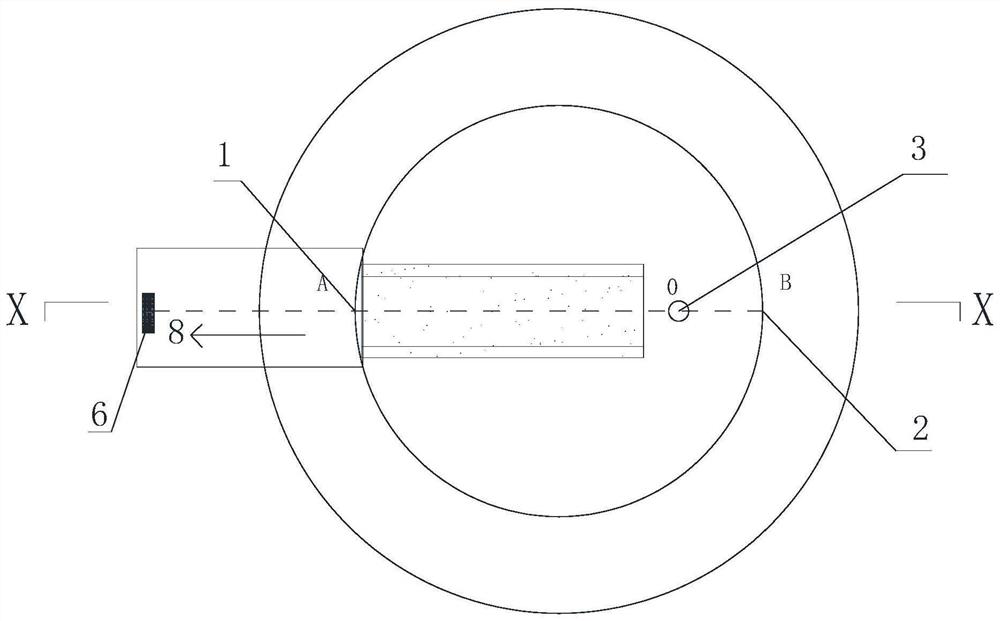

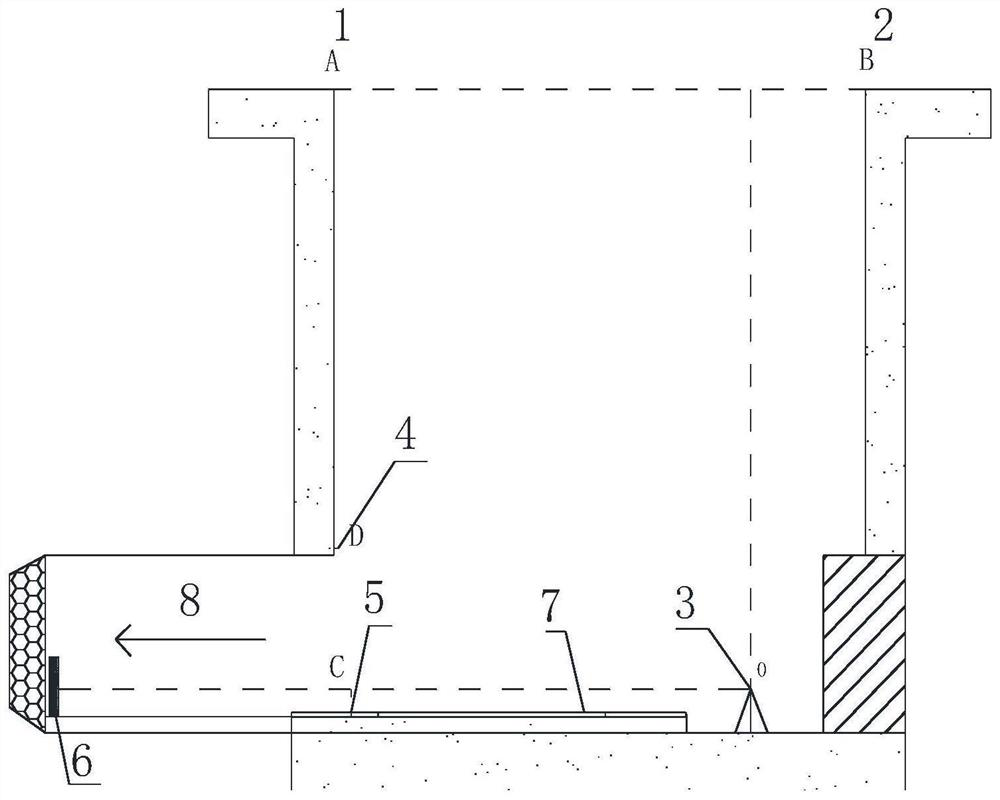

A monitoring and control method for pipe jacking construction

ActiveCN112049648BTo achieve the purpose of correctingImprove selection accuracySurveying instrumentsHeight/levelling measurementArchitectural engineeringStructural engineering

The invention discloses a monitoring and control method for pipe jacking construction. Including: set the axis datum point A and point B according to the pipe jacking design requirements, set the axis direction control point D at the starting hole in the foundation pit, set the elevation control point C on the foundation of the excavation guide rail, and set the target target on the tunnel face; Lead the axis reference point to the 0 point of the laser level on the base of the working well; aim the vertical line emitted by the laser level at point D and the target to check the axis and control the axis direction; aim at point C through the vertical line emitted by the laser level The elevation is used as the backsight point to check with the target, and the elevation is controlled; according to the deviation data on the measurement light target, the pipe jacking excavation is corrected. The invention adopts the laser level combined with the hanging wire method, and uses the centering air bubble of the laser level to center the center of the hanging wire hammer as a reference point, and the cross ray of the level is aimed at the axis point of the front section, and the axis and elevation are checked by projecting the ray on the target on the face of the tunnel. In order to achieve the purpose of correction.

Owner:中国水利水电第七工程局成都水电建设工程有限公司

Pipe-jacking construction monitoring control method

ActiveCN112049648ASolve cumbersome operating proceduresEasy to operateSurveying instrumentsHeight/levelling measurementStructural engineeringControl theory

The invention discloses a pipe-jacking construction monitoring control method. The pipe-jacking construction monitoring control method comprises the steps that an axis reference point A and an axis reference point B are arranged according to pipe-jacking design requirements, an axis direction control point D is arranged at a starting hole in a foundation pit, an elevation control point C is arranged on a tunneling guide rail base, and a target is arranged on a tunnel face; the axis reference points are led to a laser level arrangement position zero point on a working well base surface; the point D is aimed through a vertical line emitted by a laser level to check the axis with the target, and the axis direction is controlled; the elevation of the point C is aimed through the vertical lineemitted by the laser level to serve as a rear view point to check with the target, and the elevation is controlled; and deviation rectification is conducted on pipe-jacking tunneling according to deviation data on a measuring light target. The laser level is combined with a suspension wire method, the center of a suspension wire plumb bob is centered through center bubbles of the laser level to serve as a datum point, a cross ray of the laser level aims at a front-section axis point, and the ray is projected to the target on the tunnel face for checking the axis and the elevation, so that thepurpose of deviation rectification is achieved.

Owner:中国水利水电第七工程局成都水电建设工程有限公司

Honeycomb plate compounding equipment

PendingCN114506107ATo achieve the purpose of correctingGuaranteed accuracyDomestic articlesMetal working apparatusHoneycombLaboratory oven

The invention relates to cellular board compounding equipment, and relates to the field of cellular board preparation, the cellular board compounding equipment comprises a heating device, a compounding device, a drying oven, a cooling device, a trimming device, a cutting device, a conveying device and a collecting device which are arranged in sequence, and a deviation rectifying device is arranged between the cooling device and the trimming device; sensing devices used for detecting the two side edges of the plate are arranged between the cooling device and the deviation rectifying device and between the trimming device and the cutting device. The deviation rectifying mechanism comprises a bottom plate and a supporting frame rotationally arranged on the bottom plate, the supporting frame is provided with an upper conveying roller and a lower conveying roller which are used for conveying plates, the bottom plate is provided with a driving part used for driving the supporting frame to rotate, and the driving part and the sensing device are jointly connected with a controller. The plate conveying device has the effects of correcting the plate conveying direction and improving the overall production efficiency.

Owner:苏州金纬片板膜智能装备有限公司

Automatic mesh belt correcting device

ActiveCN112478602ANo human intervention requiredGuaranteed uptimeConveyorsControl devices for conveyorsRotational axisElectric machinery

The invention provides an automatic mesh belt correcting device which comprises a correcting bottom plate and a correcting mounting plate, wherein the correcting mounting plate is arranged on the topof the correcting bottom plate, and a rotating shaft is arranged on the correcting mounting plate; a correcting wheel is arranged on one side of the correcting bottom plate, a bearing with a pedestalis arranged at the axis of the correcting wheel, and a connecting bearing is arranged on one side of the bearing with the pedestal. The automatic mesh belt correcting device drives a motor to rotate to drive a crankshaft to operate to be linked with a moving connecting block, a pulling connecting guide bar and a connecting bearing to move linearly, and meanwhile, to drive the correcting mounting plate to rotate at a certain angle around the rotating shaft and to feed back to a photoelectric switch. When the photoelectric switch is of no signal, i.e. the mesh belt correction is adjusted, a purpose of correcting the mesh belt is finally achieved. Online operation detection and real-time correction of the mesh belt are achieved, and manual intervention is removed, so that long-term reliable operation of the device is ensured and the operation efficiency is improved greatly.

Owner:HENGLI ELETEK

Steel bar horizontal stress application deviation rectifying method

PendingCN112431359AEasy to operateGood correction effectBuilding reinforcementsBuilding material handlingRebarJackscrew

The invention provides a steel bar horizontal stress application deviation rectifying method. The root of a steel bar stretching out of a prefabricated concrete component serves as a fulcrum, a horizontal force is applied to the middle of the steel bar stretching out of the prefabricated concrete component through a jack, and a self-balancing loading steel bar deviation rectifying device is designed through a counter force provided by the fulcrum of the root of the steel bar. According to the method, the device is used for limiting the top end of the steel bar stretching out of the prefabricated concrete component, and by virtue of an auxiliary positioning plate, the steel bar stretching out of the prefabricated concrete component is pushed to the position required by steel bar design, sodeviation rectification of the steel bar is achieved.

Owner:HUNAN UNIV +1

A kind of inspection device and inspection method based on belt drive

ActiveCN112283560BImprove stabilityGuaranteed uptimeConveyorsMachine supportsReciprocating motionTrackway

The invention discloses a belt transmission-based inspection device and inspection method, which belong to the technical field of inspection. The device includes columns, which are arranged vertically; there are two tracks, which are parallel to each other and arranged side by side on the top of the columns; belts, which are arranged around the tracks along the length direction of the tracks; and drive units, which drive the belts to reciprocate; It also includes a motion platform, which is arranged above the track, and the motion platform is connected to the belt drive; a cleaning brush, which is located at the front end of the motion platform, cleans the upper surface of the track with the movement of the motion platform; the motion platform is equipped with patrol inspection items required pieces. The inspection device based on belt transmission of the present invention has the advantages of simple structure, low cost, easy processing and assembly, large bearing capacity, good stability, strong adaptability, self-cleaning and the like.

Owner:CHINA UNIV OF MINING & TECH

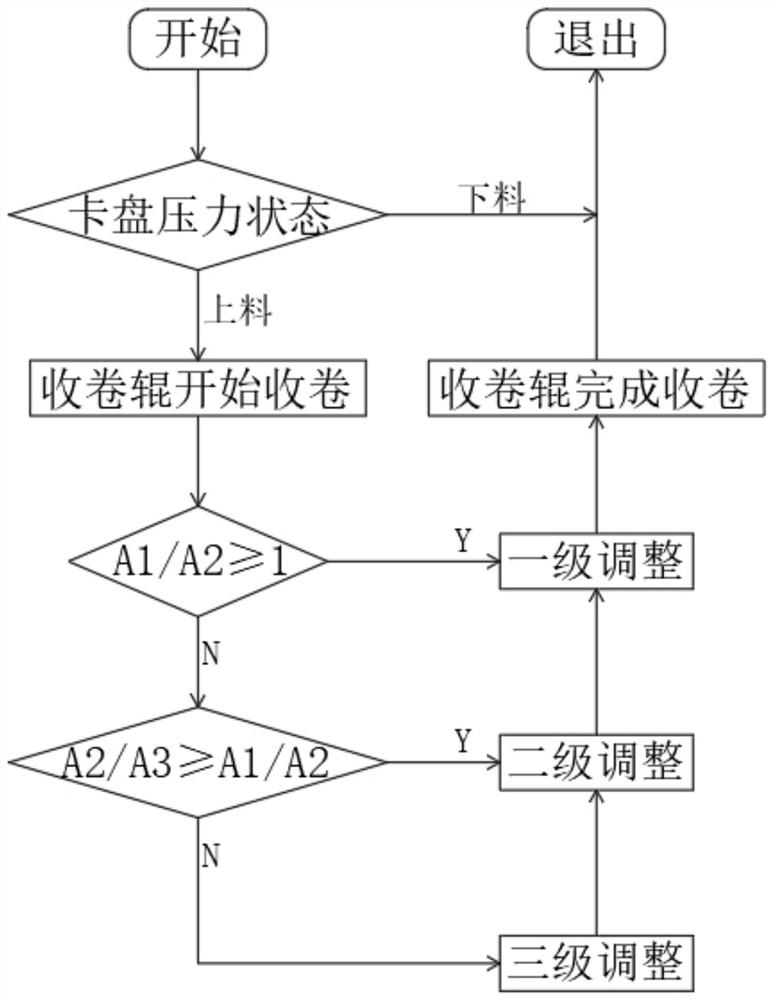

Control system for automatic feeding of casting blank plate material

PendingCN113104634AReduce workloadEnsure continuityWebs handlingTotal factory controlEngineeringManufacturing engineering

The invention relates to a control system for automatic feeding of a casting blank plate material. The control system comprises a plate material conveying belt, a chuck, a winding roller, a signal acquisition unit, a control unit and a driving unit, wherein, the chuck is responsible for grabbing the casting blank plate material on a plate material conveying belt to the winding roller, and the signal acquisition unit is divided into three groups of signal sources which are respectively placed at the plate material conveying belt, the chuck and the winding roller. Compared with an existing automatic feeding system, the control system has the advantages that through a simple comparison algorithm, the aim of deviation correction of a casting blank plate coiled material can be effectively achieved, the workload of manual detection is reduced, the production continuity is guaranteed, the production efficiency is greatly improved, and the requirement of large-scale production of enterprises can be met.

Owner:INNER MONGOLIA LIANSHENG NEW ENERGY MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com