Deviation rectifying device of tubular belt conveyor

A deviation correction device, a tubular belt type technology, is used in conveyors, conveyor objects, transportation and packaging, etc. It can solve the problems of conveyor belt deviation, uneven conveyor belt pressure, unstable conveyor belts, etc., and achieve high deviation correction accuracy. , The effect of correcting deviation is good, and the effect of ensuring production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

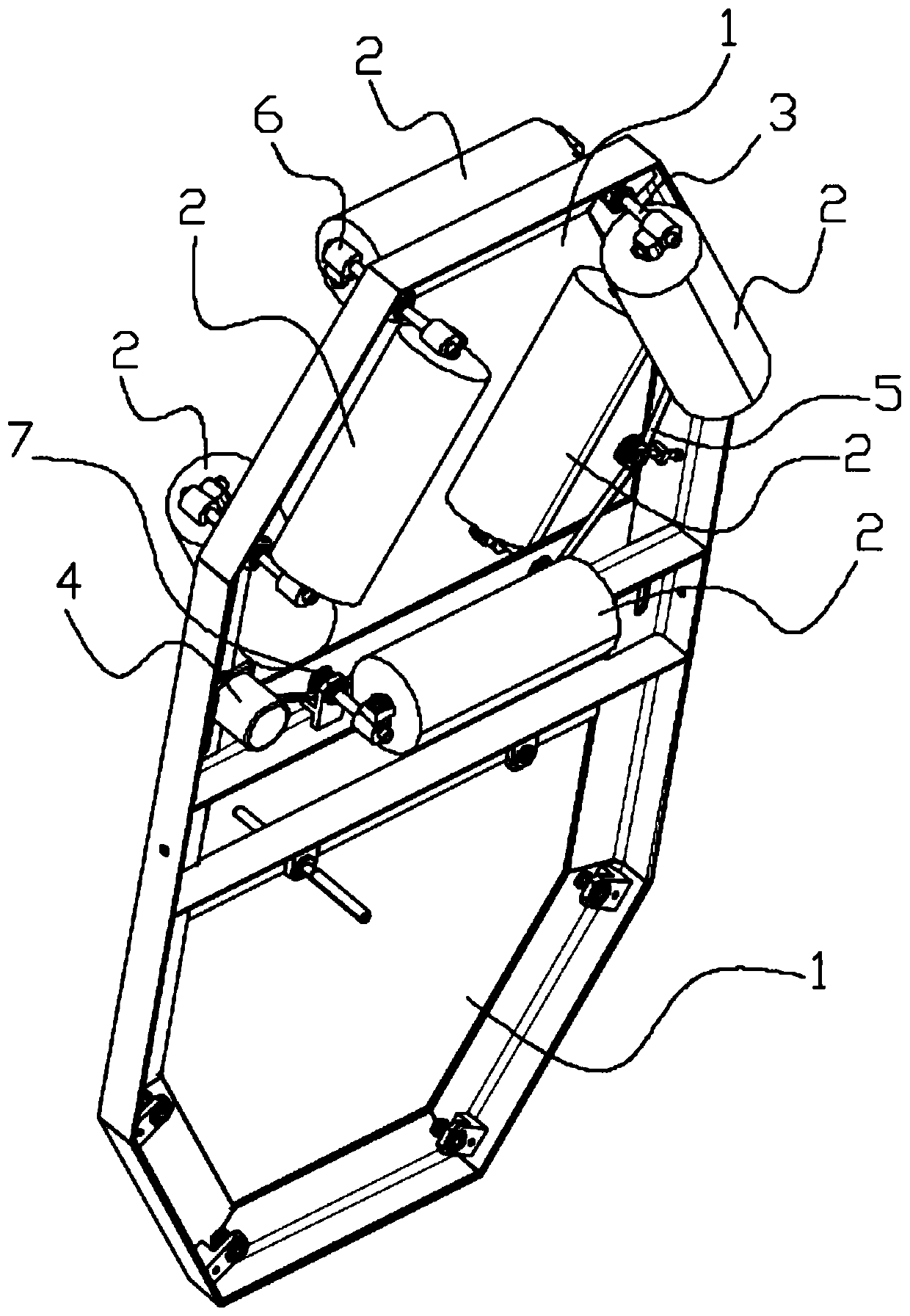

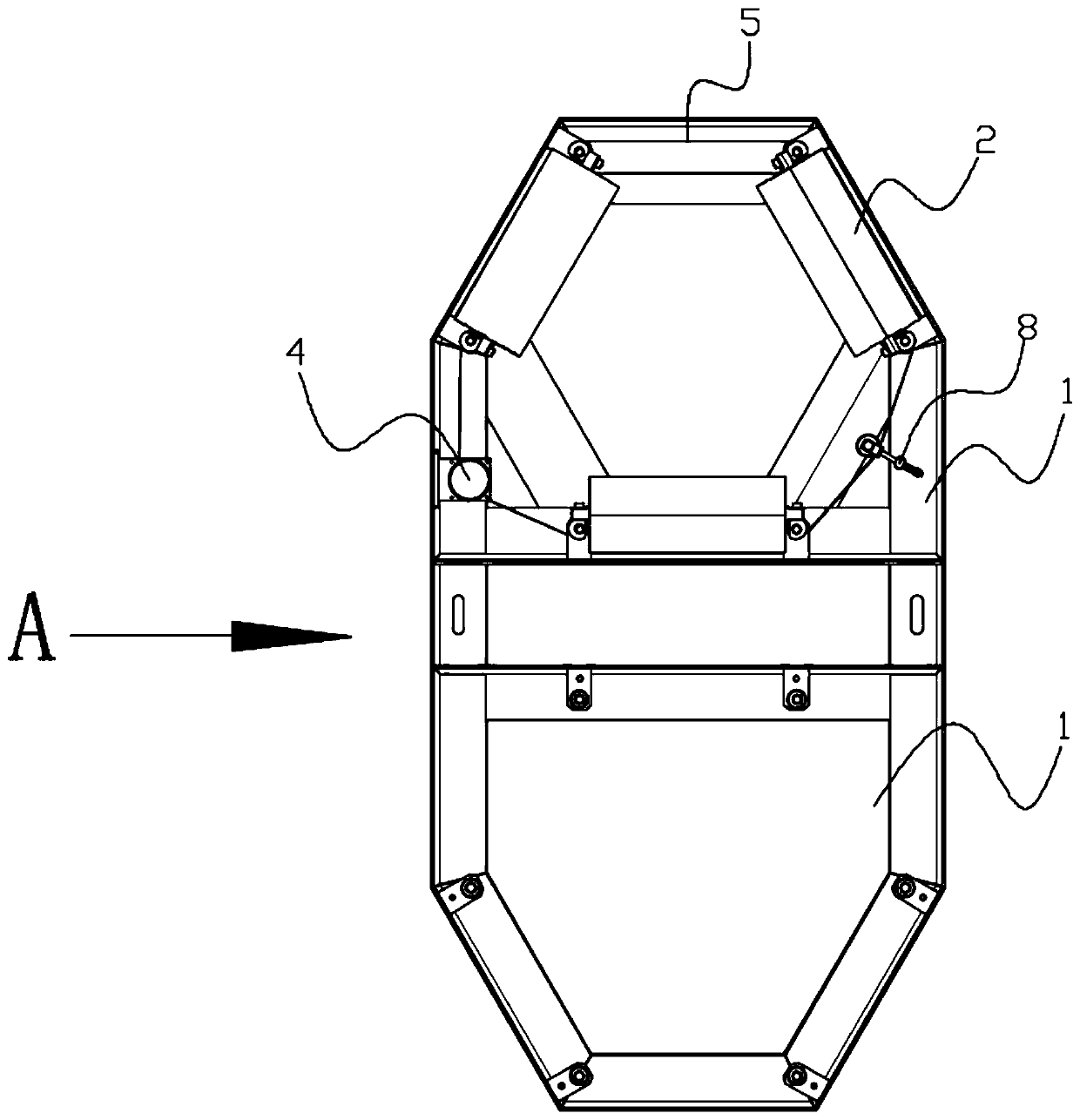

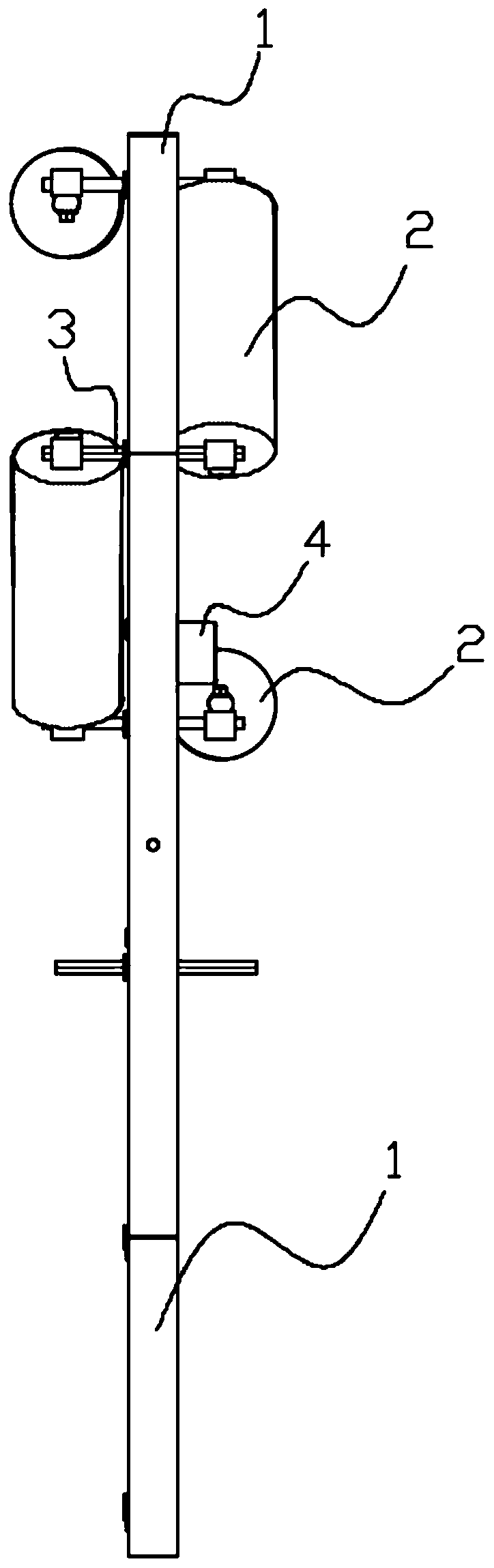

[0030] Such as Figure 1-3 As shown, because the specific structure on the shuttle frame 1 below is the same as the specific structure on the shuttle frame 1 above, therefore Figure 1-3 The specific structure on the shuttle-shaped frame 1 in the middle and lower part is not shown in the figure. A deviation correction device for a tubular belt conveyor includes two integrally formed shuttle-shaped frames 1, and the two shuttle-shaped frames 1 are arranged symmetrically up and down. A shuttle-shaped frame 1 is a hexagonal structure, and one side of each side of each shuttle-shaped frame 1 is provided with an idler 2 and the idler 2 on the adjacent side is respectively arranged on both sides of the shuttle-shaped frame 1;

[0031] The joints of the adjacent sides of each shuttle-shaped frame 1 are provided with positive and negative screw rods 3, and the positive and negative screw rods 3 run through both sides of the shuttle-shaped frame 1, and the adjacent positive and negativ...

Embodiment 2

[0036] The difference between this embodiment and Embodiment 1 is that the positive and negative motors and the positive and negative screw rods are synchronously driven by sprocket transmission, and the fixed connection here can be realized by key fit or screw fit to realize the tilting of the idler roller. Angle adjustment; sprocket drive means that each positive and negative screw rod is fixedly connected with a gear, and the output shaft of the positive and negative motor and the gear are connected to realize transmission.

[0037] Both embodiment 1 and embodiment 2 can communicate with the existing automatic control system to realize the automatic control or semi-automatic control of the deviation correction device of the tubular belt conveyor; The position switch or video detection mechanism for the torsion angle of the conveyor belt, the position switch or video detection mechanism is connected to the central processor by communication, and the central processor is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com