A monitoring and control method for pipe jacking construction

A monitoring control and pipe jacking technology is applied in the field of measurement and deviation correction in pipe jacking construction in sand and gravel strata, and in the field of pipe jacking construction monitoring and control, to achieve the effects of improving construction work efficiency, reliable pipe jacking construction quality control, and preventing deviations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the specific embodiments, which further illustrate the principles of the present invention and do not limit the present invention in any way, and the same or similar technologies as the present invention do not exceed the protection scope of the present invention.

[0021] In conjunction with the attached drawings.

[0022] The monitoring and control method of pipe jacking construction includes the following steps:

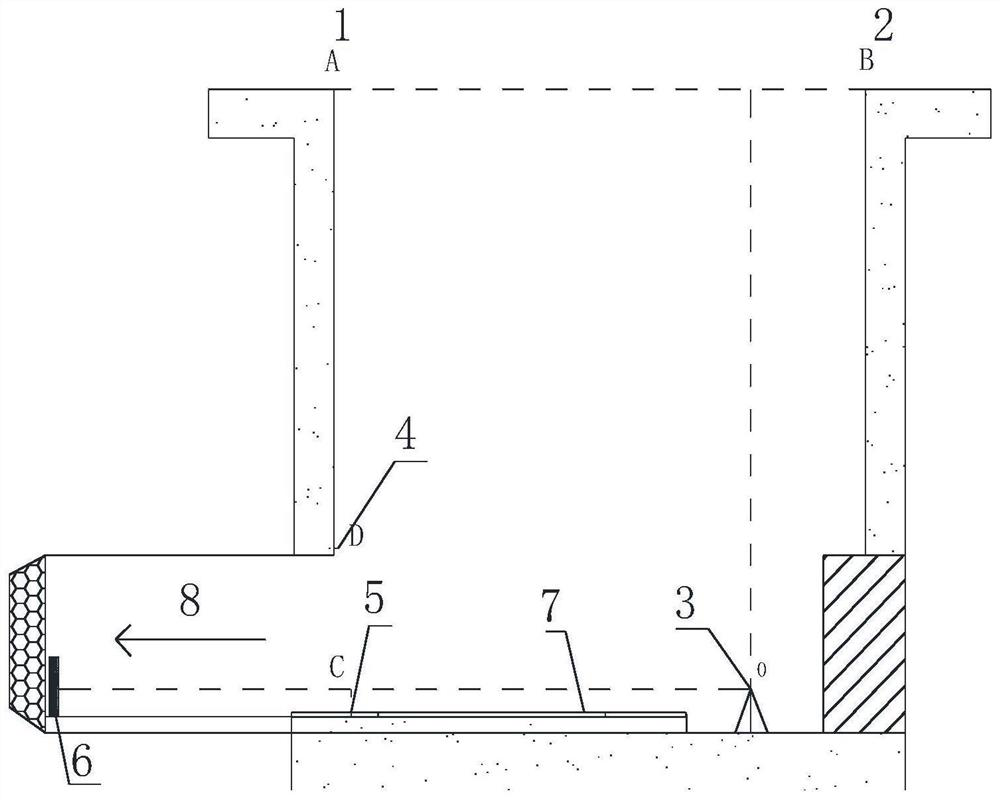

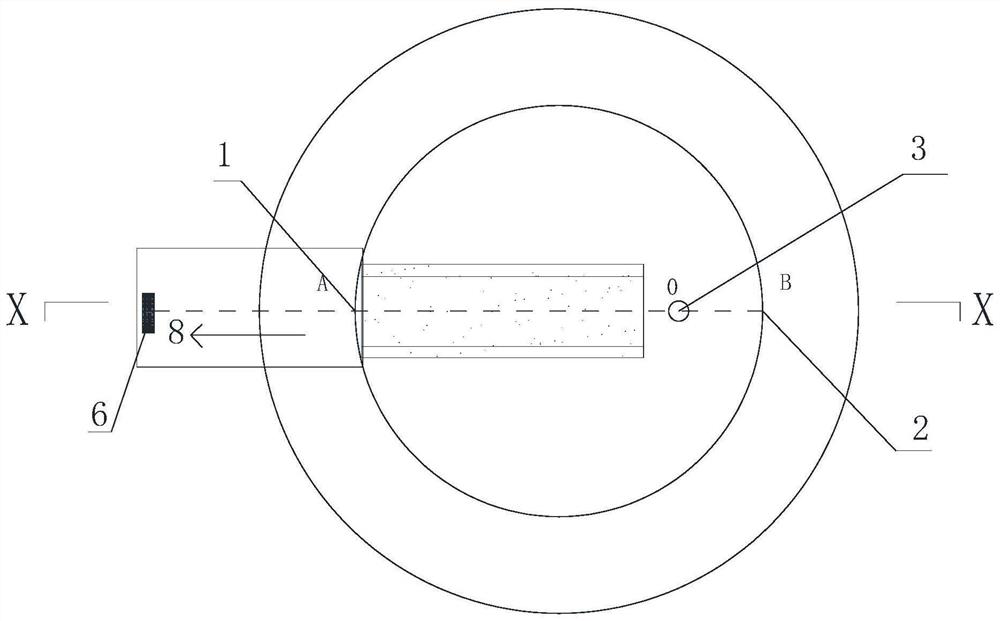

[0023] (1) Preparation work: Before the pipe jacking construction, use the total station to set the axis reference point A 1 and the axis reference point B point 2 on the top surface of the working well according to the pipe jacking design requirements, and the connecting line between the two points is the pipe jacking design axis; In addition, a total station is used to set the axis direction control point D 4 at the starting hole in the foundation pit of the working well, the elevat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com