A kind of inspection device and inspection method based on belt drive

A technology of belt transmission and transmission connection, which is applied in the field of inspection, can solve the problems of damage, short effective life of the transmission mechanism, etc., and achieve the effect of increased load, compact structure and low cost of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

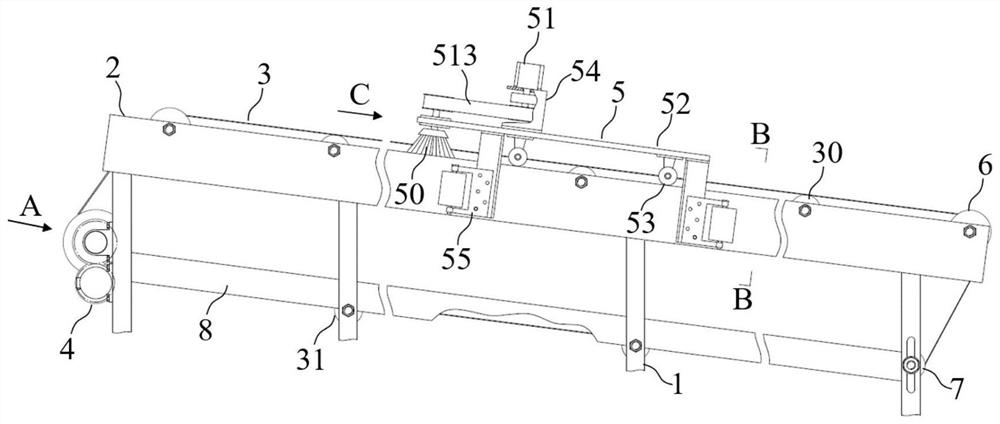

[0073] The inspection device based on belt drive in this embodiment includes,

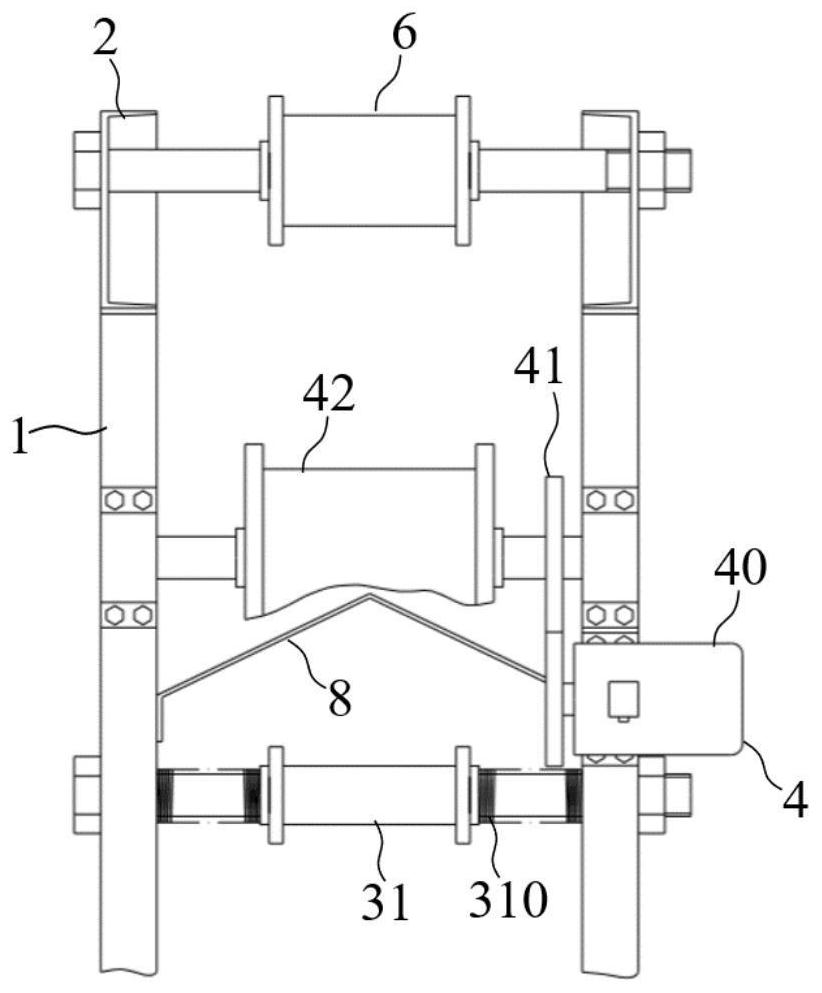

[0074] Upright column 1, it has several, all vertical arrangement;

[0075] There are two rails 2, parallel to each other, arranged side by side on the top of the column 1;

[0076] a belt 3 arranged around the track 2 along the length direction of the track 2;

[0077] A drive unit 4, which drives the belt 3 to reciprocate;

[0078] Also includes:

[0079] The motion platform 5 is arranged above the track 2, and the motion platform 5 is connected with the belt 3 through transmission;

[0080] Cleaning brush 50, which is located at the front end of the moving platform 5, cleans the upper surface of the track 2 along with the movement of the moving platform 5;

[0081] The inspection parts required by the inspection items are arranged on the moving platform 5 .

[0082] Since the inspection process does not require heavy loads, it is only necessary to keep the inspection parts moving stably. Th...

Embodiment 2

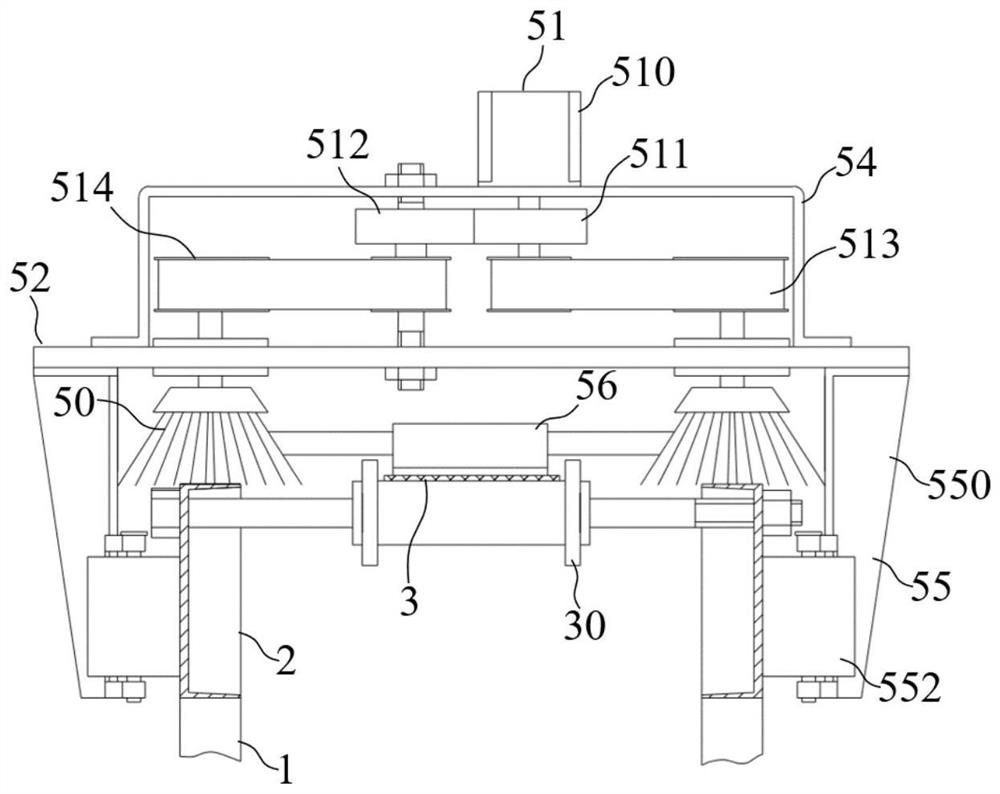

[0088] The inspection device based on the belt transmission of this embodiment is further improved on the basis of Embodiment 1, and the motion platform 5 includes:

[0089] Cleaning drive mechanism 51, which is connected with the cleaning brush 50 in transmission, and drives the cleaning brush 50 to rotate;

[0090] A flat plate 52, which is arranged above the track 2 parallel to the track 2, and the inspection parts are arranged on the flat plate 52;

[0091] Support wheel 53, it is located between flat plate 52 and track 2, and flat plate 52 is supported on track 2;

[0092] The support frame 54 is fixed on the top surface of the front end of the flat plate 52 and supports the cleaning driving mechanism 51 .

[0093] Such as figure 1 with image 3 As shown, the present embodiment is provided with a cleaning drive mechanism 51 to drive the cleaning brush 50 to rotate. When the moving platform 5 moves, the cleaning drive mechanism 51 is started to further strengthen the cl...

Embodiment 3

[0095] The inspection device based on belt transmission in this embodiment is further improved on the basis of Embodiments 1 and 2. There are two cleaning brushes 50, which are respectively arranged above the two rails 2; the cleaning drive mechanism 51 includes :

[0096] Driving part 2 510, which provides driving force;

[0097] gear one 511, which is arranged horizontally, and is connected to the output end of drive part two 510;

[0098] Gear two 512, which is horizontally arranged next to gear one 511 and meshes with gear one 511;

[0099] The belt transmission mechanism 1 513 is horizontally arranged below the gear 1 511, the input end of the belt transmission mechanism 1 513 is connected to the gear 1 511, and the output end is connected to a cleaning brush 50;

[0100] The second belt transmission mechanism 514 is horizontally arranged below the second gear 512 , the input end of the second belt transmission mechanism 514 is connected to the second gear 512 , and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com