Glass bearing module with deviation rectifying function

A technology for carrying modules and glass, which is applied in manufacturing tools, parts of grinding machine tools, and machine tools suitable for grinding the edge of workpieces, etc. It can solve the problems of stress concentration, fragmentation, lack of sufficient support, etc., and achieve uniform force , Guarantee the effect of quality and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

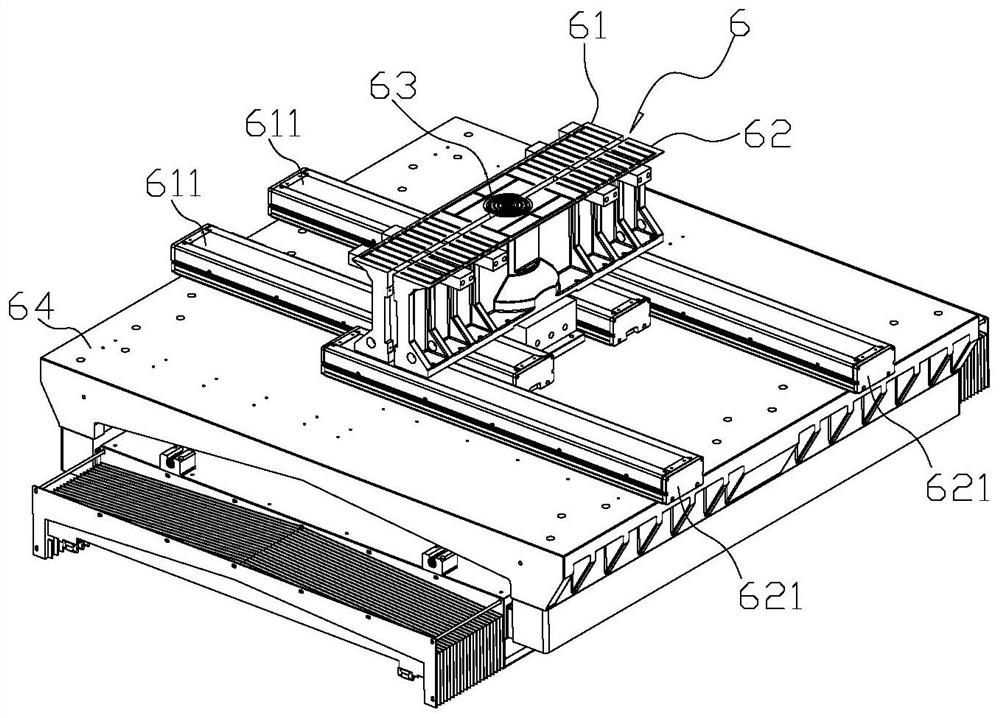

[0016] See Figure 1-3 It is shown that it is a glass bearing module with deviation correcting function, which is applied to a fully automatic glass loading, unloading, edging and cleaning production line. The glass bearing module is used for bearing and positioning glass.

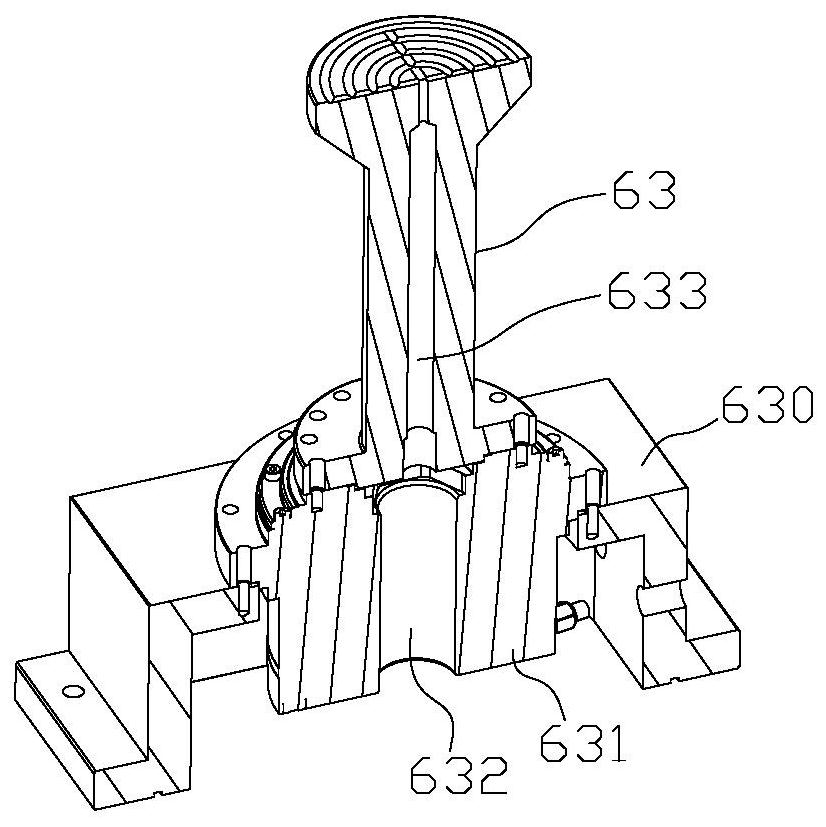

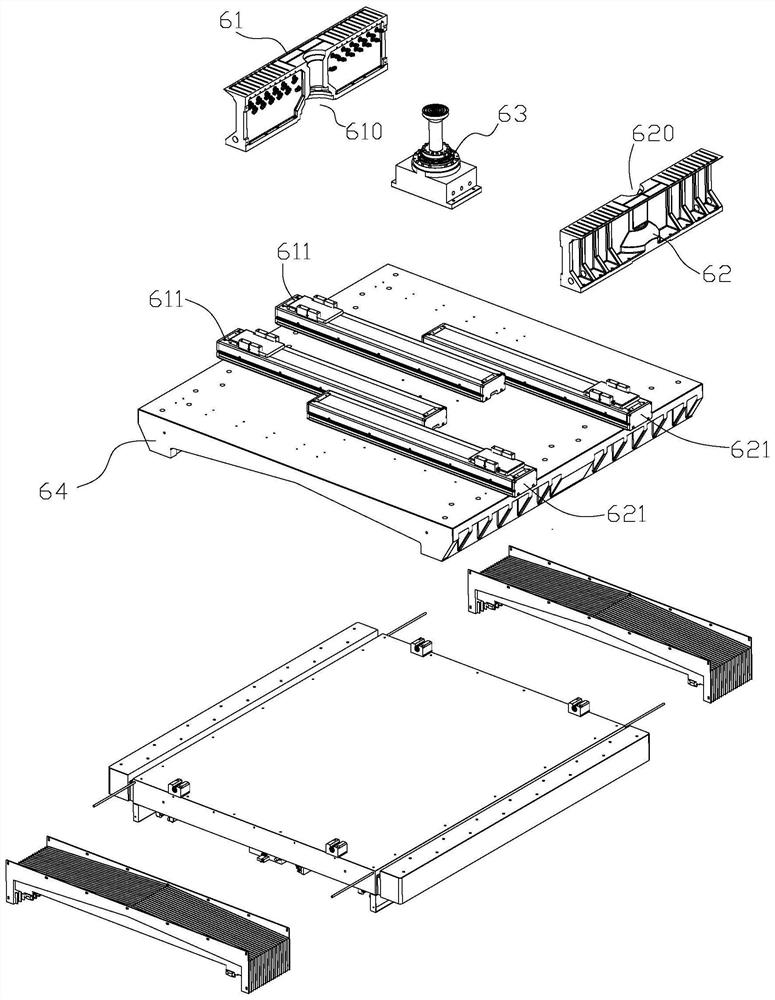

[0017] See Figure 1-3 As shown, the above-mentioned glass carrying module 6 includes a carrying base 64, a first movable seat 61 and a second movable seat 62 that are installed on the carrying base 64 and can run relatively, and a set for cooperating with the first movable seat 61 and the second movable seat. Two movable seats 62 carry glass or a rotating seat 63 that corrects the deflection of glass, wherein the rotating seat 63 is located between the first movable seat 61 and the second movable seat 62, and the first movable seat 61 and the second movable seat 62 pass throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com