Method for constructing underground continuous wall by using cutter-suction head

A technology of underground diaphragm wall and cutter suction, applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve problems such as construction difficulties, achieve the effect of fast excavation, increase construction speed, and ensure safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

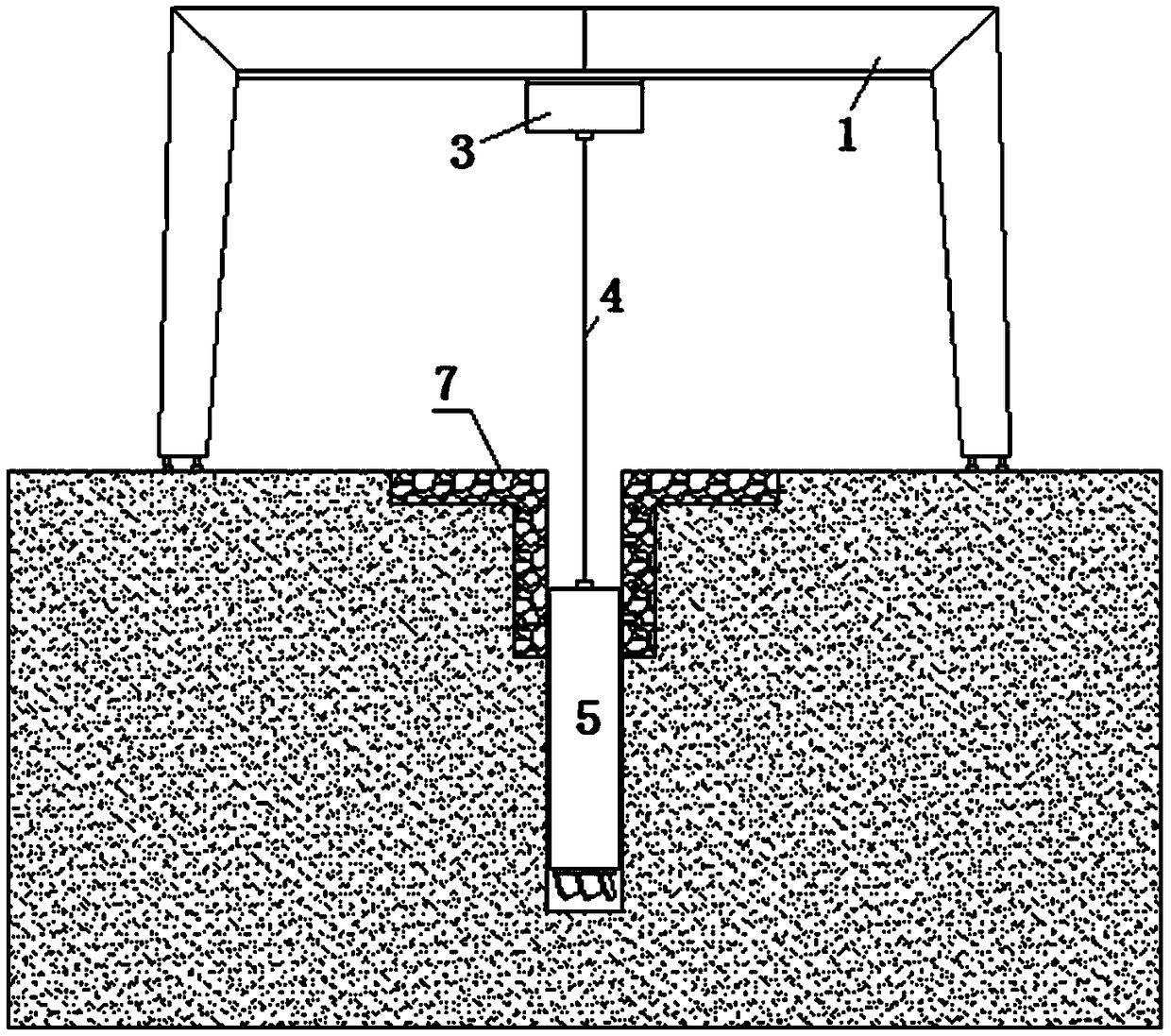

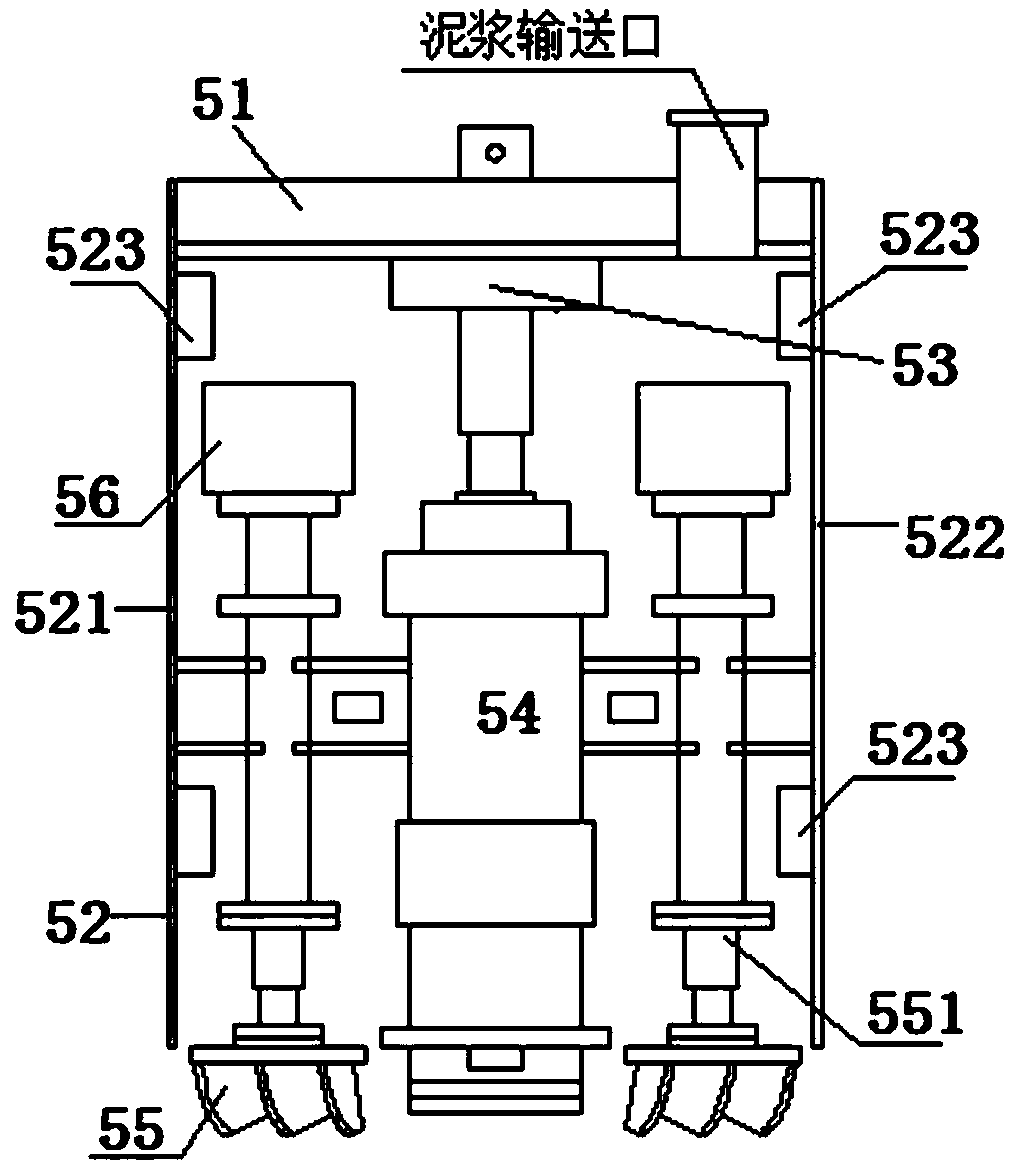

[0026] Such as figure 1 , figure 2 The illustrated embodiment is a method for constructing an underground diaphragm wall using a twisted suction head, including five cranes 1, a mud-water separator, a track 3 arranged on the lower surface of each crane, and a driving power device arranged on the track to pass through The wire rope 4 is connected with the hinge suction head 5; the hinge suction head includes a beam 51, a rectangular tube 52 arranged on the beam at the upper end and a lower end opening, a hydraulic device 53 connected to the middle part of the lower surface of the beam, and a slurry connected to the connecting rod of the hydraulic device. The pump 54 is arranged on two reamers 55 on both sides of the mud pump; the mud pump is fixedly connected to the connecting shafts 551 of the two reamers respectively, and the two connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com