An automatic folder gluer

A folder-gluer and automatic technology, applied in container manufacturing machinery, box making operations, paper/cardboard containers, etc., can solve the problems of product qualification rate reduction, economic loss, paper feeding inclination, etc., to overcome the problem of waste products, large economy benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

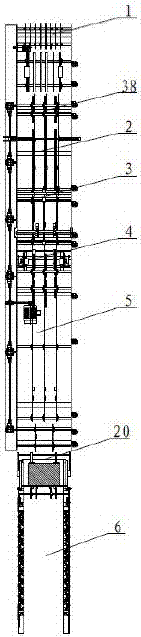

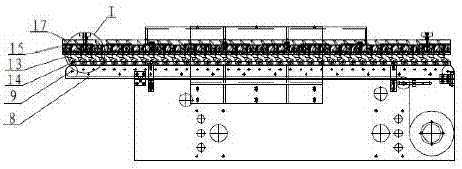

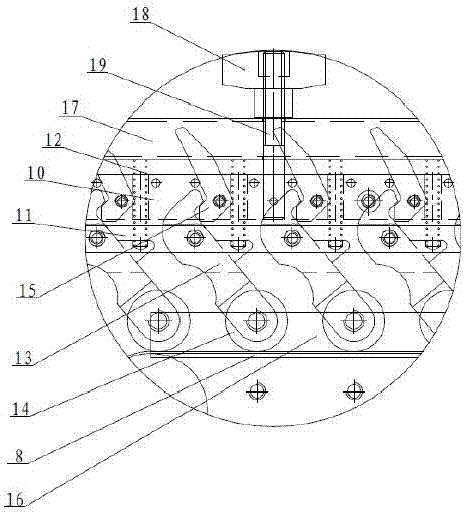

[0026] Embodiments of the present invention will be further described below with reference to the accompanying drawings:

[0027] An automatic folder-gluer, comprising a paper output device 1, a return device 2, a hook bottom device 3, a lower paste device 4, a main folding device 5 and a conveying device 6 distributed in sequence, the paper output device 1 and the return device 2 A deviation correction device 7 is arranged between them, and the deviation correction device 7 includes a transmission mechanism and a correction mechanism, and the transmission mechanism includes a first belt 8 and a first pulley 9, and the first belt 8 is used to convey cardboard, and the correction mechanism It includes a first bracket 10, a mounting plate 11, a first elastic member 12, a swing arm 13, a roller 14, a limiter 15 and a baffle 16, the swing arm 13 is hinged on the mounting plate 11, and the roller 14 is hinged on the On the swing arm 13, the limiting member 15 is fixed on the mounti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com