Deviation correcting structure and method of horizontal locking broken column

A technology of horizontal locking and fracture, which is applied in infrastructure engineering, building construction, building maintenance, etc., can solve problems such as broken column correction, existing building safety risks, and house dumping, and achieve the effect of avoiding dumping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

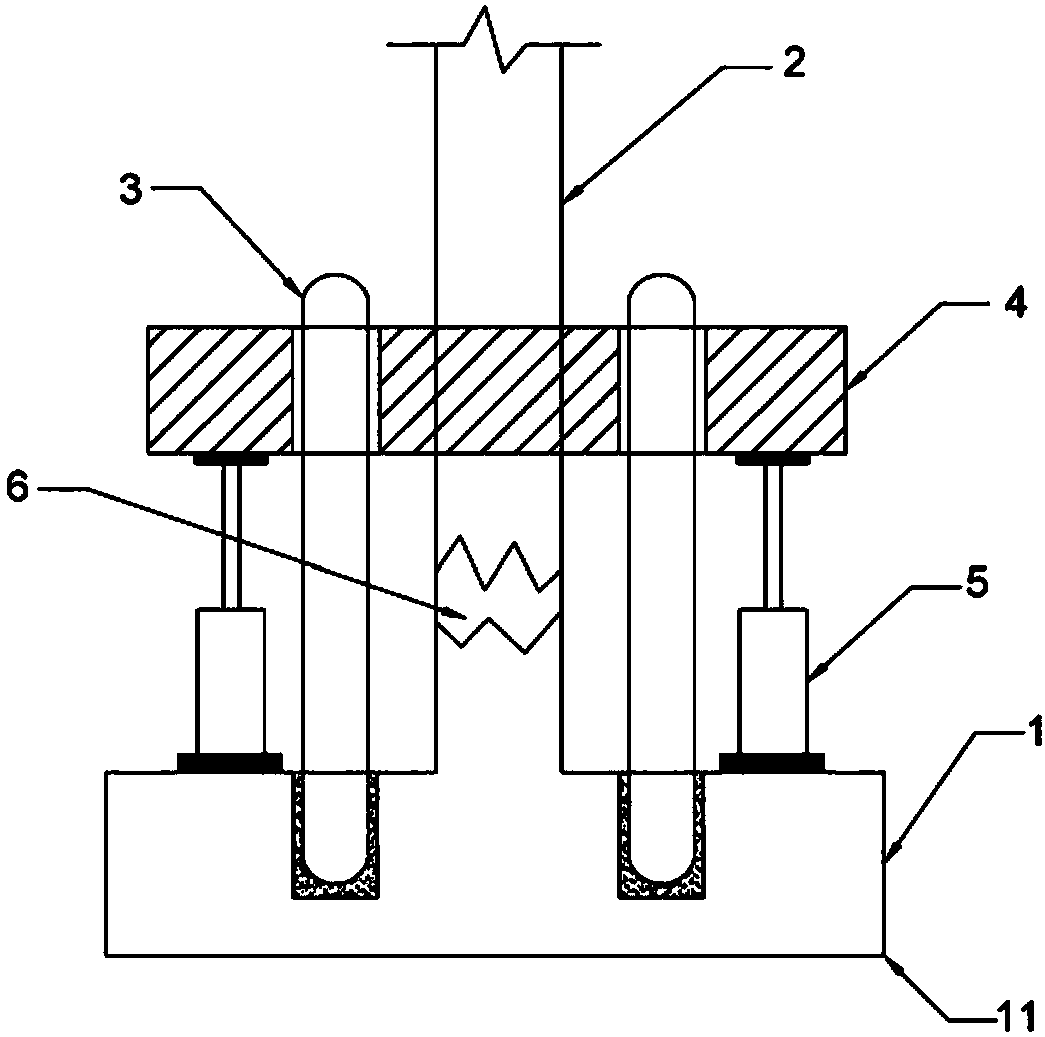

[0032] like figure 1 As shown, a deviation correction structure for horizontally locking a broken column includes a building foundation 1 and a load-bearing column 2, the load-bearing column 2 is provided with a fracture 6, and the periphery of the load-bearing column 2 is fixedly connected with a column-holding tray 4, so The fracture 6 is located between the column-holding tray 4 and the building foundation 1, and at least two support piles 3 are arranged around the load-bearing column 2, and one end of the support pile 3 is embedded in the building foundation 1. The other end of the support pile 3 is pierced through the pillar-holding tray 4 , and a jacking device 5 for jacking up the pillar-holding tray 4 is provided below the pillar-holding tray 4 .

[0033] The load-bearing column 2 is the load-bearing column 2 of the original building. In this embodiment, the jacking device 5 is a jack. In other embodiments, other jacking devices 5 can be selected. One end of the suppo...

Embodiment 2

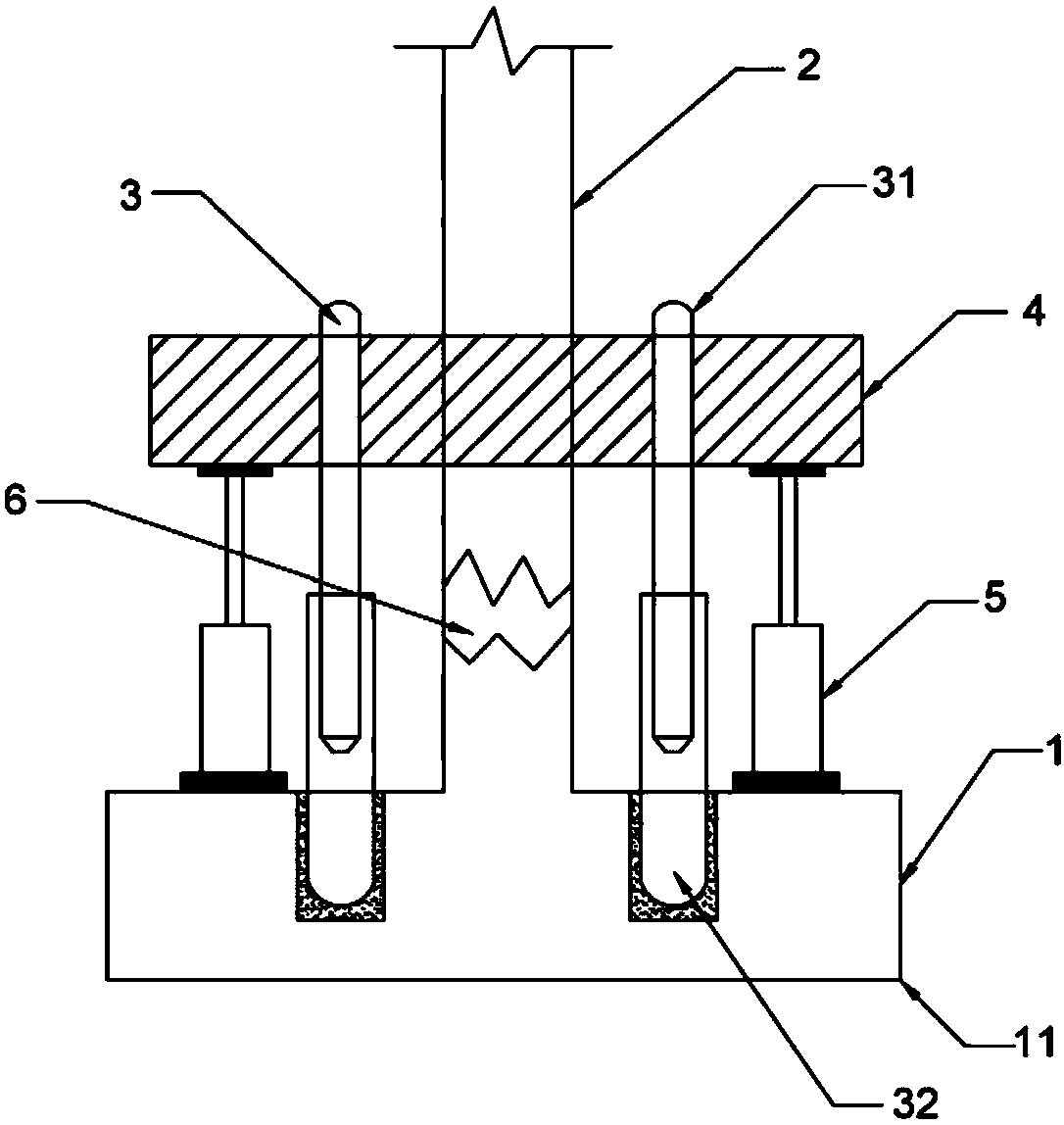

[0038] like figure 2 As shown, the difference between this embodiment and Embodiment 1 is that each of the support piles 3 includes a lower support pile 32 embedded in the building foundation 1 and an upper support pile 31 pierced through the pillar-holding tray 4 , the upper supporting pile 31 is slidably sleeved in the lower supporting pile 32 , and the upper supporting pile 31 can only move away from the lower supporting pile 32 .

[0039] The lower support pile 32 is buried in the building foundation 1, the upper support pile 31 is fixed with the support tray 4, and the upper support pile 31 is sleeved in the lower support pile 32, and can only move upward. Lifting device 5 jacks up and holds the supporting pallet 4, and the upper part of the load-bearing column 2 and the upper support pile 31 also move upwards along with the supporting pallet 4, and because the upper supporting pile 31 can only move upwards in the lower supporting pile 32. Moving downwards, in fact, the...

Embodiment 3

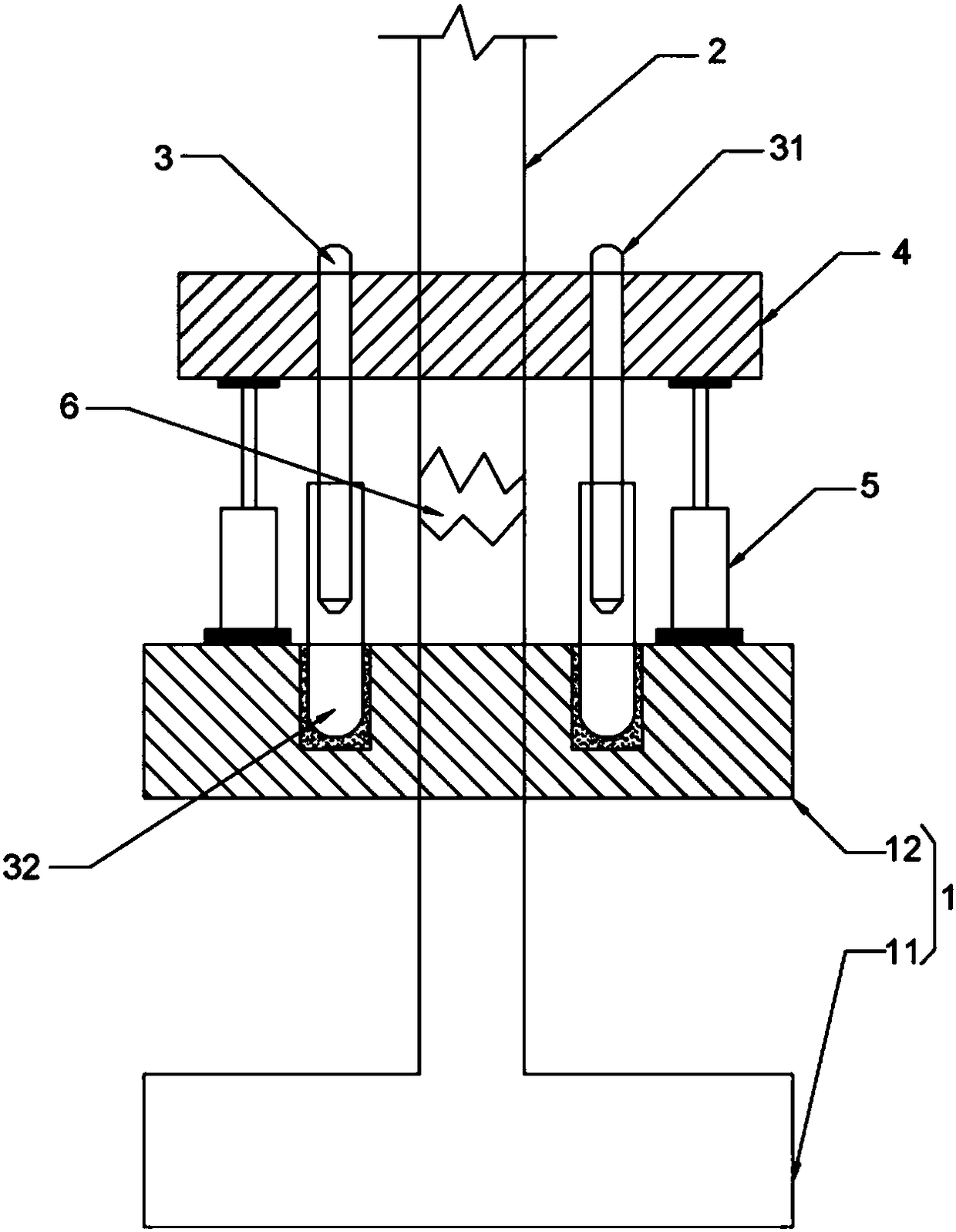

[0043] like image 3 As shown, the difference between this embodiment and implementation 1-2 is: when the original foundation 11 is deeply buried, the building foundation 1 is a new foundation 12, and the new foundation 12 is set at a place where the ground bearing capacity is sufficient, and the next The support pile 32 is embedded in the newly added foundation 12, and the disconnection is opened between the newly added foundation 12 and the pallet on the pillar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com