Plate deviation correction device and deviation correction method

A deviation correction device and plate technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve problems such as unfavorable processing, plate tilting, uneven machine connection, etc., to achieve the effects of reducing impact, enhancing load capacity, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

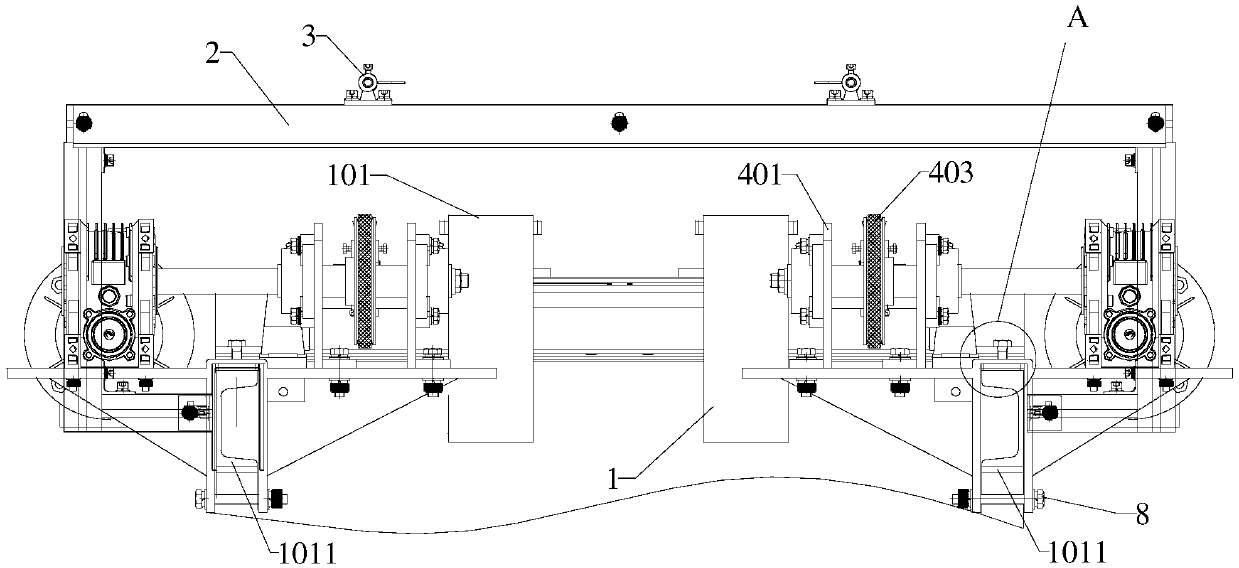

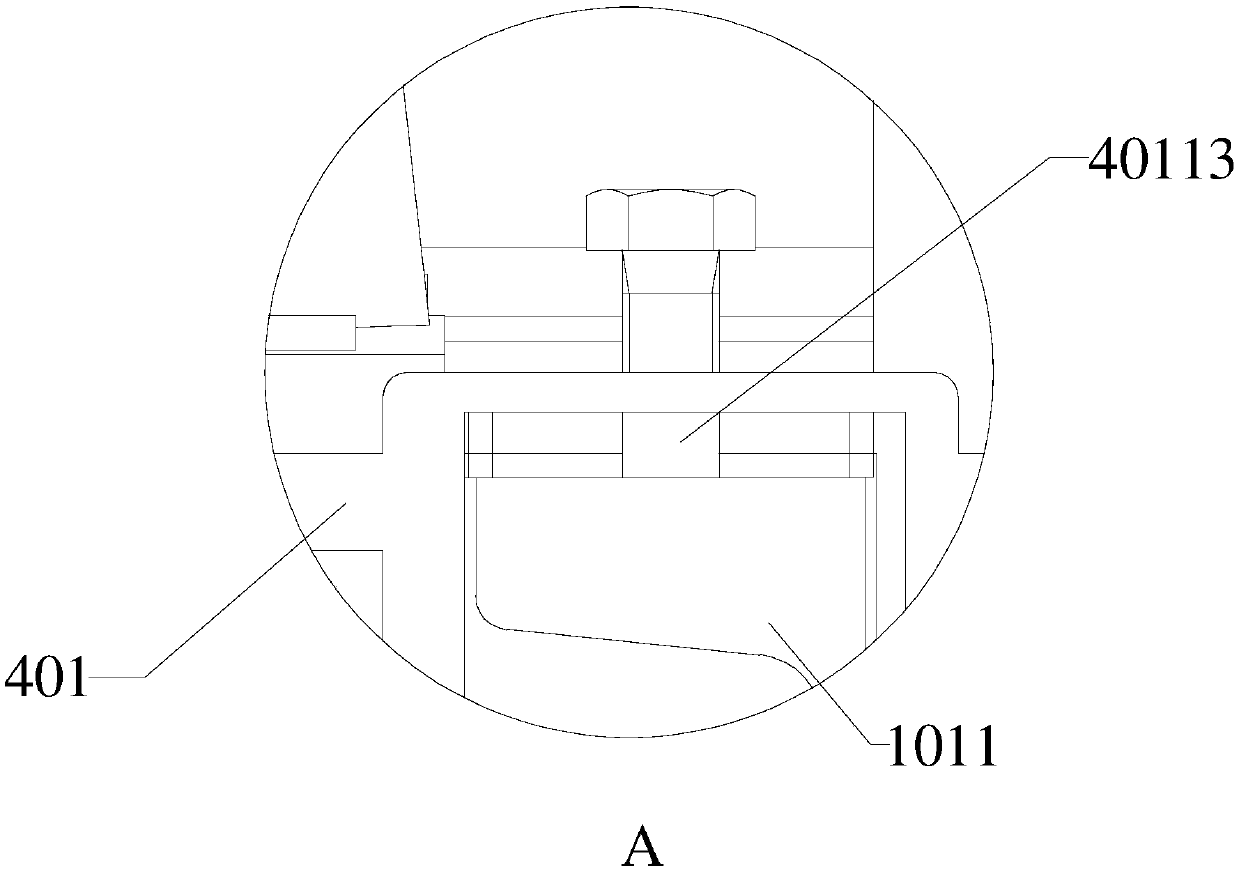

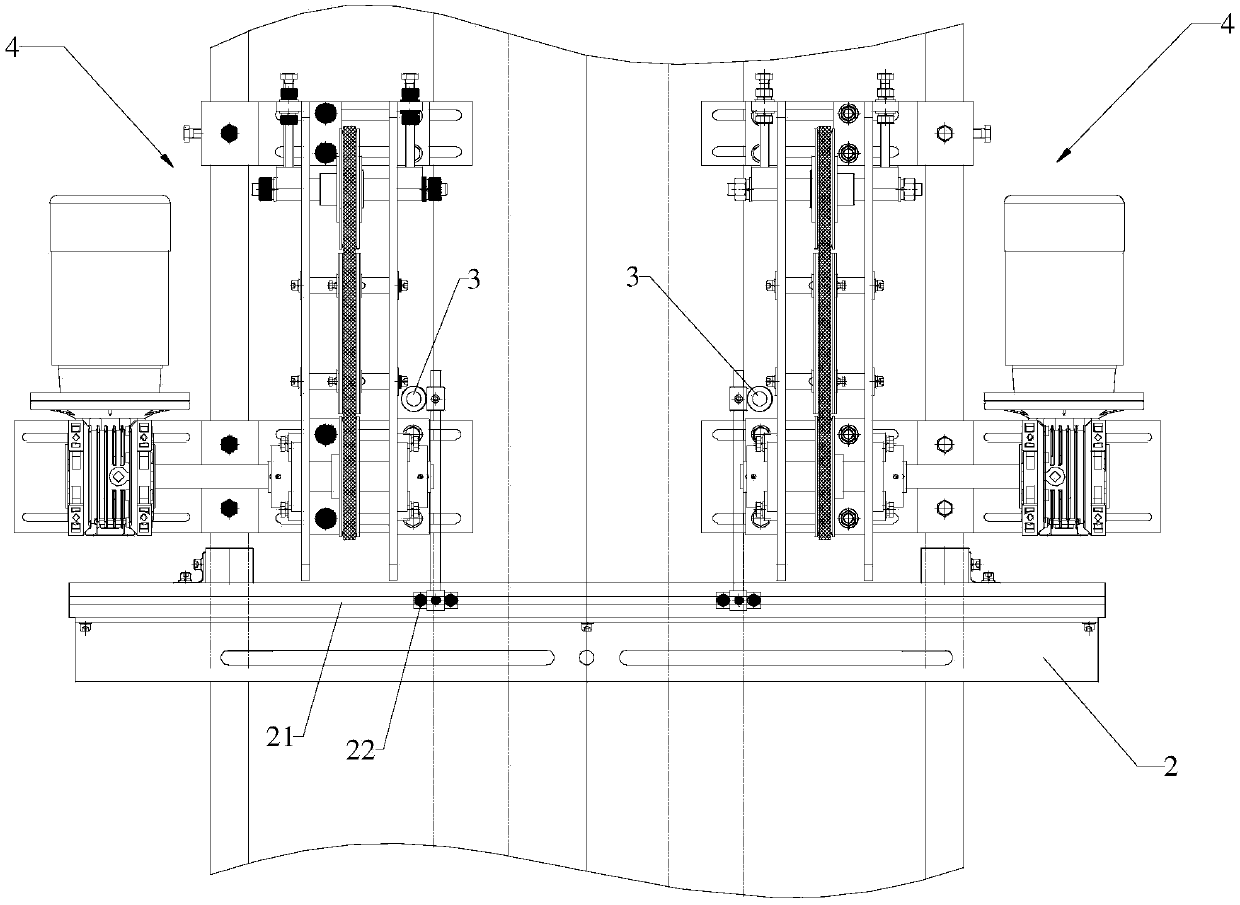

[0060] refer to figure 1 , this embodiment discloses a sheet material deviation correction device, including a conveying chassis 1, the conveying chassis 1 is provided with a support platform 101, the plate 7 is placed on the supporting platform 101 for transmission, and the conveying chassis 1 is provided with a detection area And the deviation correction area, the detection area is provided with a support beam 2 and two plate edge detectors 3, the support beam 2 is fixedly connected with the conveying chassis 1, the support beam 2 is perpendicular to the conveying direction of the conveying chassis 1, and the two plate edge detection The detectors 3 are arranged at intervals on the support beam 2 and symmetrically arranged along the center line of the conveying chassis 1, and the connection line of the edge detectors 3 of the two plates is perpendicular to the conveying direction of the conveying chassis 1.

[0061] In this embodiment, the board edge detector 3 is a photoele...

Embodiment 2

[0077] Based on Embodiment 1, the difference between this embodiment and Embodiment 2 is that in this embodiment, the supporting beam is located below the conveying chassis, the sheet edge detector is a travel switch, and the detecting end of the sheet edge detector points to the conveying chassis and Vertical to the lower surface of the conveying chassis, the distance between the detection end of the sheet edge detector and the conveying plane is less than the thickness of the sheet, so that when the sheet passes through the sheet edge detector, the sheet and the detection end of the sheet edge detector abut to trigger the sheet edge Detector.

Embodiment 3

[0079] This embodiment discloses a deviation correction method using the plate deviation correction device in Embodiment 1, including:

[0080] S1: The plate edge detector 3 detects the conveying state of the plate 7

[0081] If the plate 7 is conveyed to the bottom of the plate edge detector 3, and the plate edge detector 3 senses the plate 7 at the same time, then the plate 7 is transported normally, skip S2, and enter S3;

[0082] If the plate 7 is conveyed to the bottom of the plate edge detector 3, and the plate edge detector 3 does not sense the plate 7 at the same time, then the conveyance of the plate 7 is deviated, and enters S2, refer to Figure 8 ;

[0083] S2: Correction

[0084] refer to Figure 9 , if among the two groups of conveying components 4, the plate edge detector 3 on the side where one set of conveying components 4 is located first senses the plate 7, as shown in the figure, the plate edge detector 3 on the right side first detects the plate 7, Then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com