Novel energy-efficient fin type electric heating pipe

An electric heating tube, high-efficiency and energy-saving technology, applied in the direction of the heating element shape, etc., can solve the problems of short service life of the electric heating tube, unsatisfactory heat dissipation effect, loose solder joints, etc., to achieve enhanced heat dissipation efficiency, good heat dissipation effect, and convenient The effect of welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

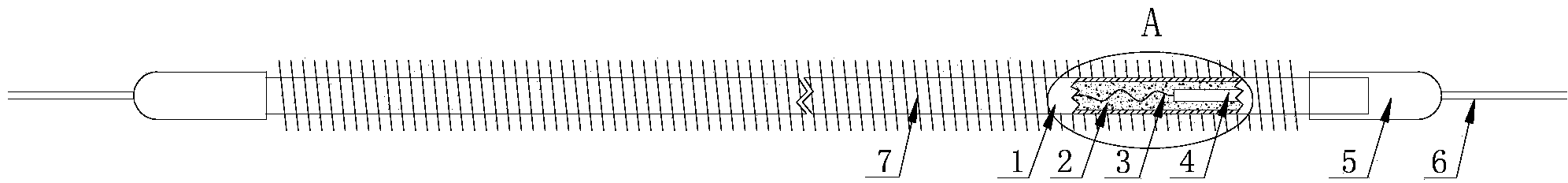

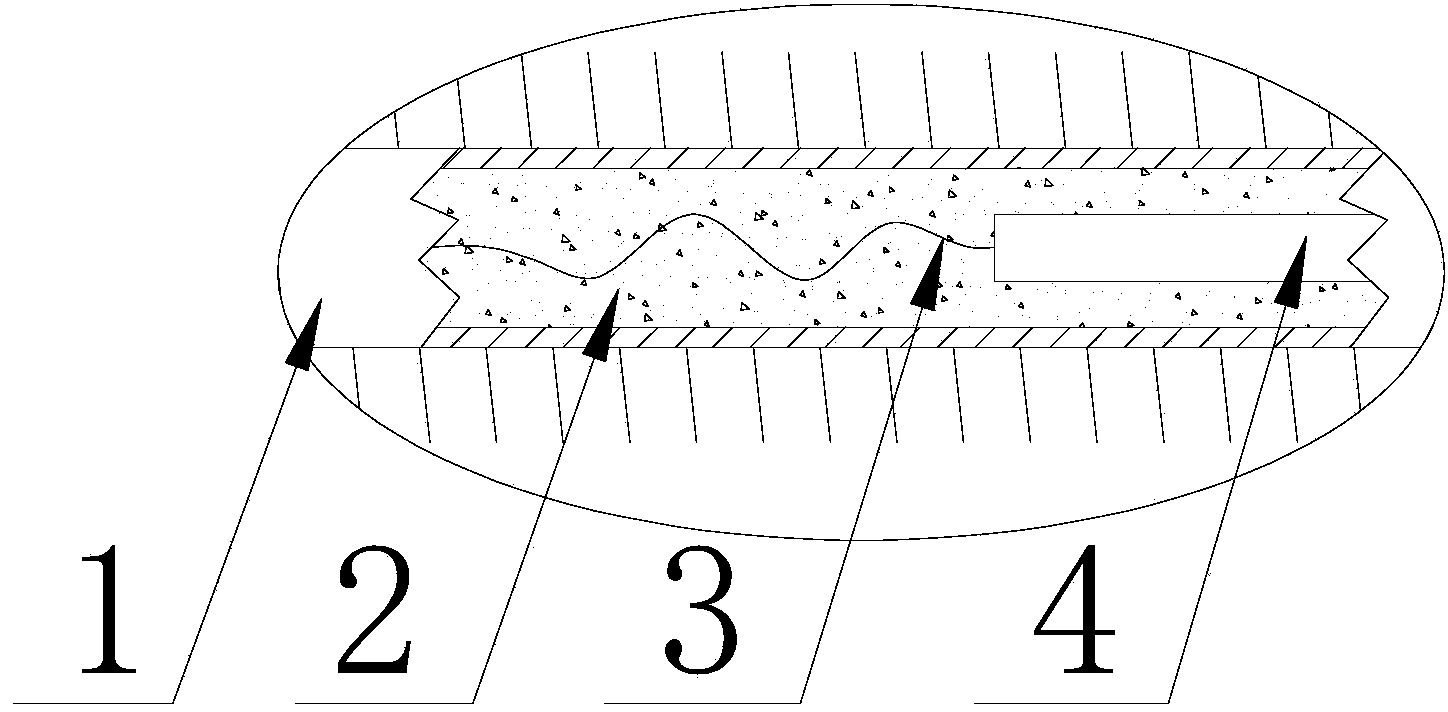

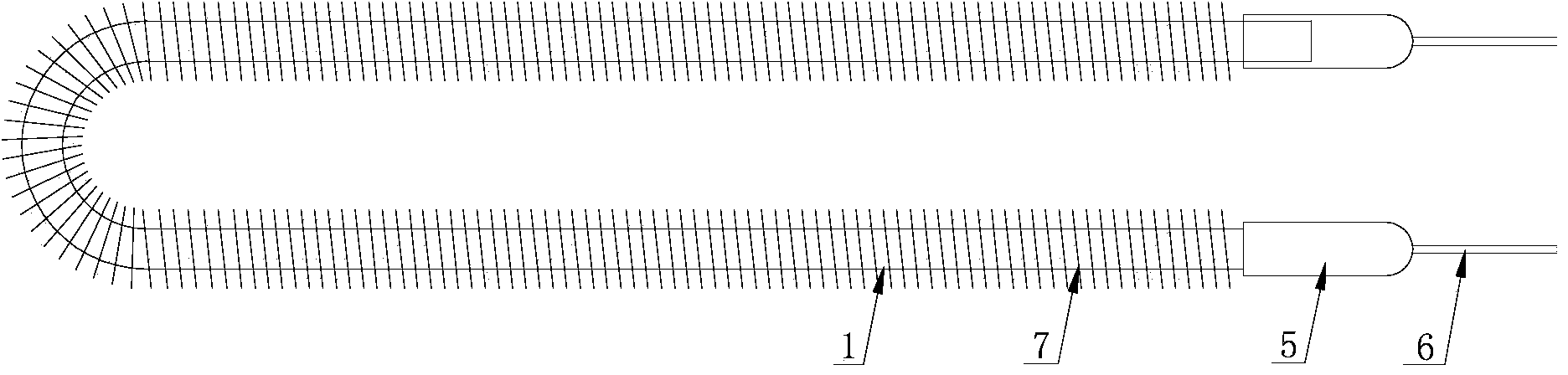

[0021] like Figure 1 to Figure 3 As shown, the new high-efficiency and energy-saving finned electric heating tube includes a shell 1, a heating wire 3 arranged in the shell 1, and a thermally conductive insulating filler 2 filled between the shell 1 and the heating wire 3. The shell 1 Mounting seats 5 are respectively provided at both ends, and terminal electrodes 4 are provided on the mounting seats 5. Strip-shaped cooling fins 7 are spirally wound on the outer surface of the housing 1. The cooling fins 7 are provided with continuously distributed A fan-shaped concave-convex structure (not shown in the figure), the constricted end of the fan-shaped concave-convex structure is close to the surface of the housing 1 , and the expanded end is close to the outer edge of the heat dissipation fin 7 .

[0022] In this embodiment, the distance between the expanded end of the fan-shaped concave-convex structure and the outer edge of the heat dissipation fin 7 is less than or equal to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com