High-tension winding ceramic disc of electronic insects killing lamp

An insecticidal lamp and high-voltage technology, which is used in devices, applications, animal husbandry, etc. to capture or kill insects, to achieve the effect of convenient winding, solving high-voltage breakdown, and convenient fixed installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

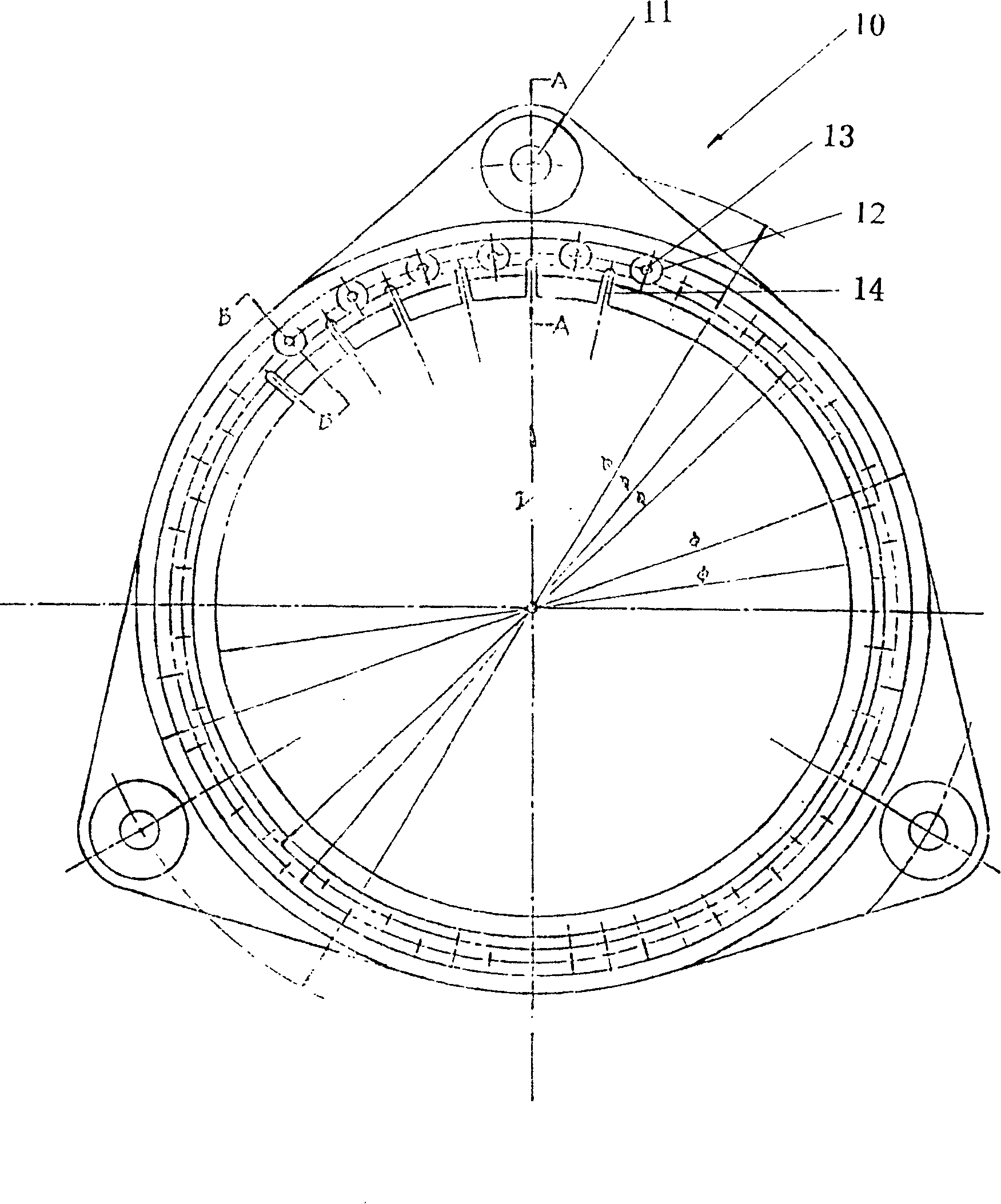

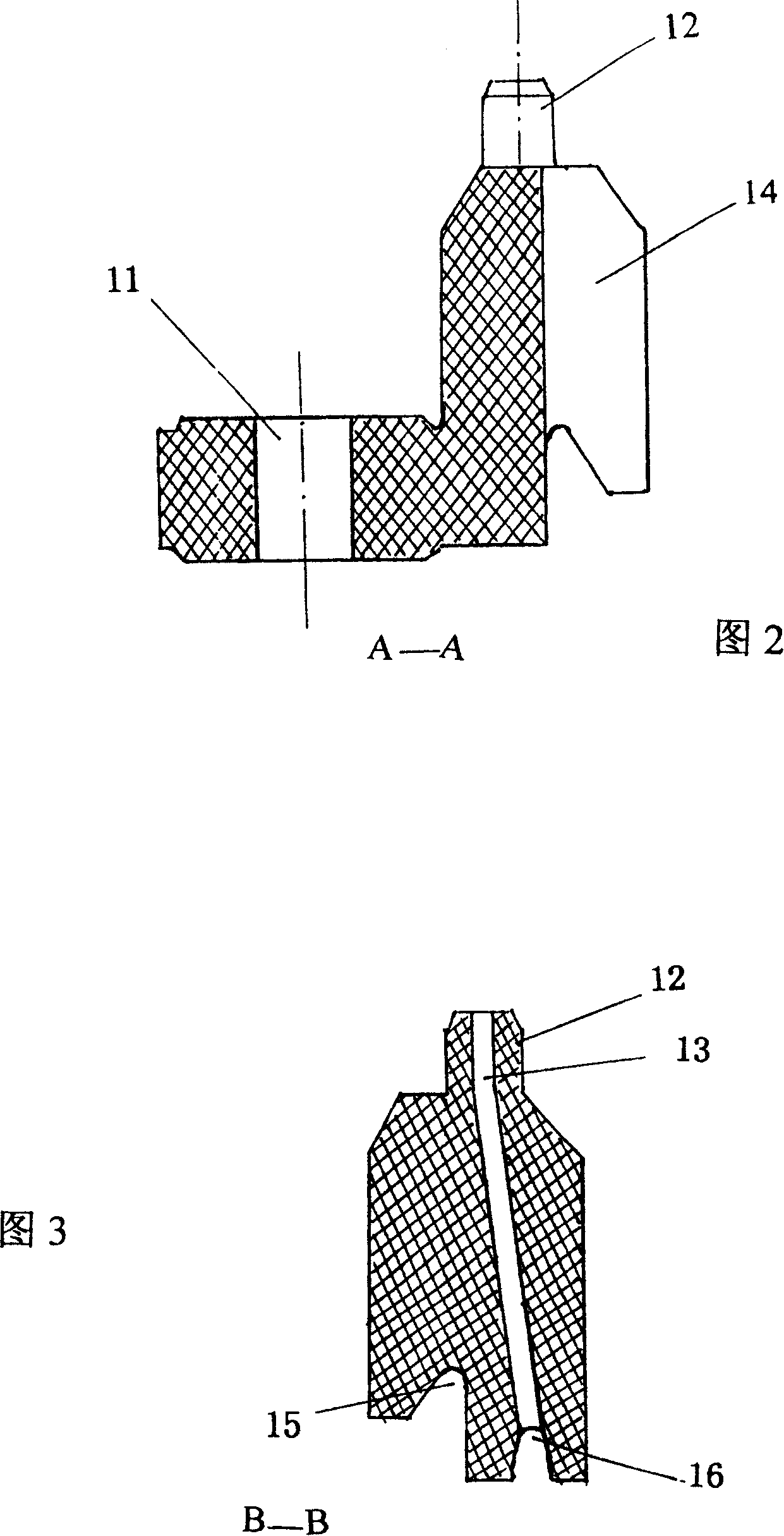

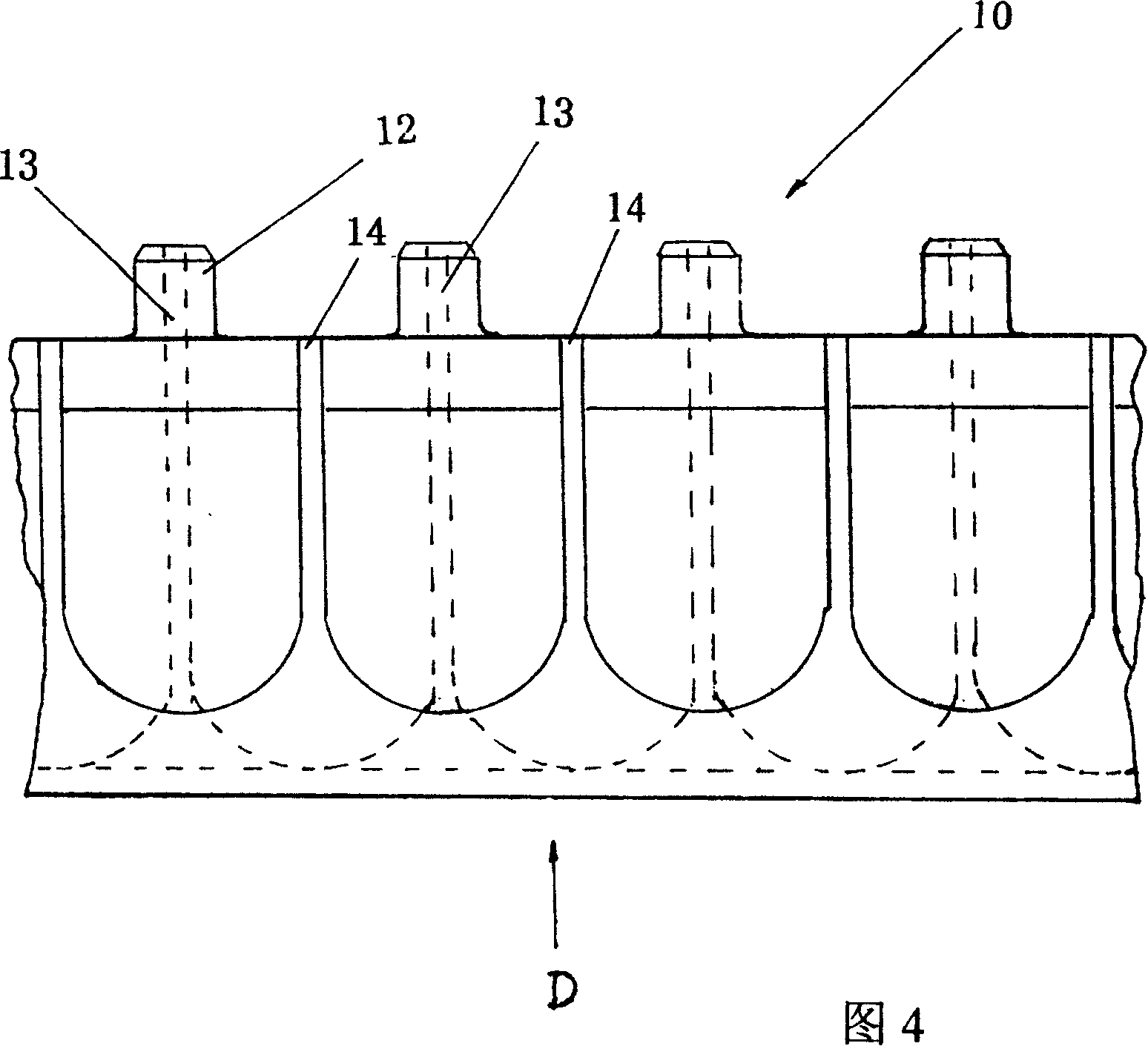

[0018] Such as figure 1 , 2, 3, and 4 are schematic diagrams of the structure of the present invention. The high-voltage wire-wound porcelain plate 10 of the electronic insecticidal lamp is installed on the upper and lower ends of the high-voltage power grid of the electronic insecticidal lamp, wherein the high-voltage wire-wound porcelain plate 10 is in the shape of a ring, and there are three fixed holes 11 around it. The upper end surface of the high-voltage wire-wound porcelain plate 10 is uniformly provided with a plurality of convex posts 12, and the center of the convex post 12 is provided with an outer layer hole 13 penetrating the ring. Outer layer grooves 16 are provided between the lower ends of the adjacent outer layer holes 13, and inner layer grooves 14 with notches facing inward and passing through the upper and lower end surfaces are arranged on the ring between these protruding posts 12, and adjacent An inner groove groove 15 is opened between the lower ends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com