Split coil structure and transformer

A technology of transformers and coils, applied in the field of transformers, can solve problems such as difficult control of output voltage matching, achieve the effects of solving the problem of short-circuit impedance mismatch, simplifying the design structure, and reducing load loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

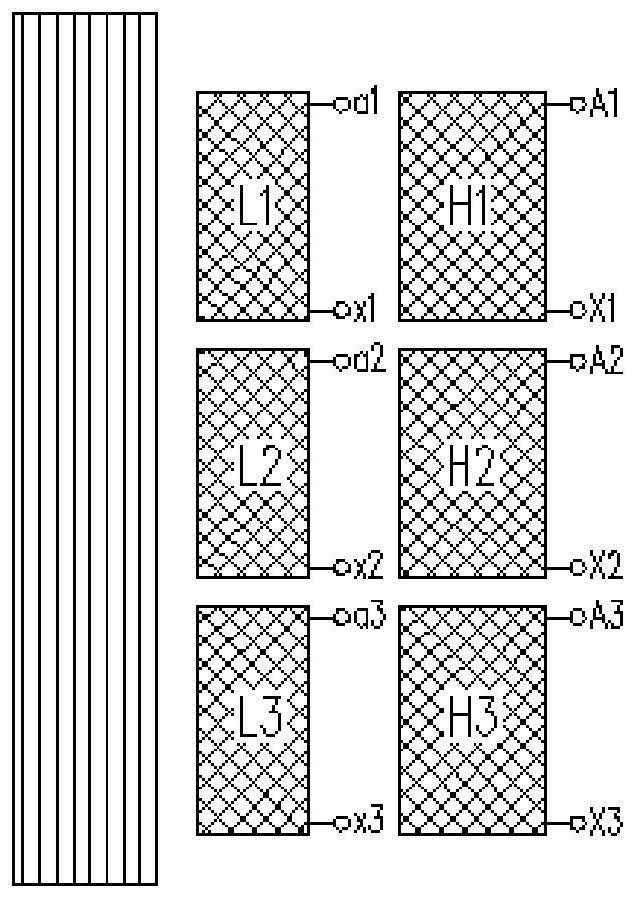

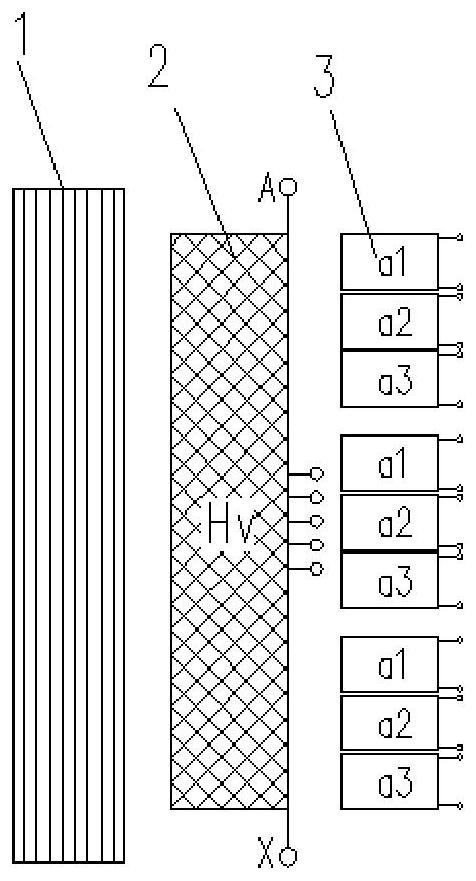

[0035] Such as Figure 2a As shown, this embodiment provides a split coil structure, including a core 1, a high-voltage winding 2 and a low-voltage winding 3, the high-voltage winding 2 and the low-voltage winding 3 are sequentially wound on the core 1, and the low-voltage winding 3 includes n The same winding units, n≥3, each winding unit is insulated from each other, each winding unit includes m split windings insulated from each other, m≥3, the corresponding same split windings in each winding unit are connected in parallel, and That is to say, the x-th split winding in each winding unit is connected in parallel with each x-th split winding in the remaining n-1 winding units, 1≤x≤m. That is, the first split winding in each winding unit is connected in parallel with each first split winding in the remaining n-1 winding units, and the second split winding in each winding unit is connected to the remaining Each of the second split windings in the n-1 winding units is connecte...

Embodiment 2

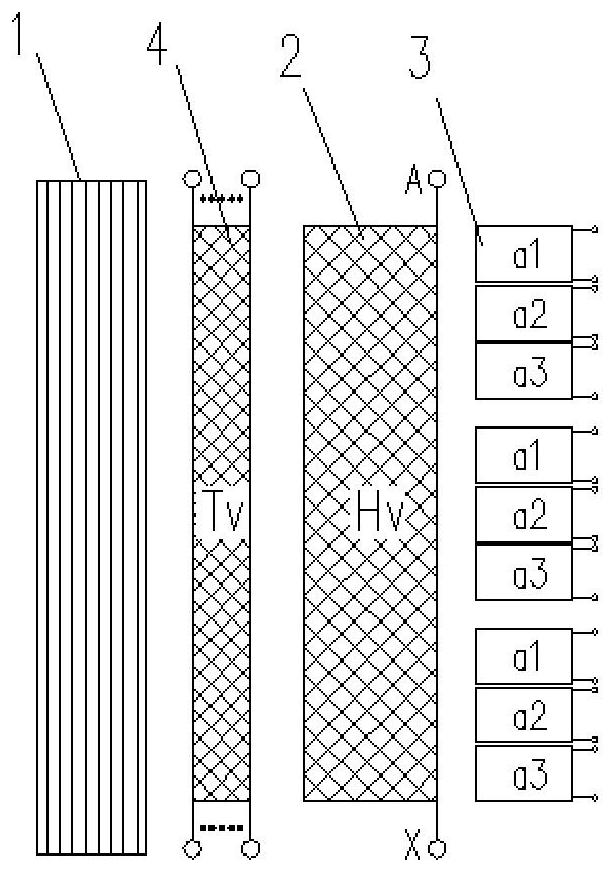

[0069] A transformer is disclosed in this embodiment, including Figure 3a / Figure 3b The split-coil configuration shown.

[0070] The split coil structure includes an iron core 1, a high voltage winding 2 and a low voltage winding 3, the high voltage winding 2 and the low voltage winding 3 are sequentially wound on the iron core 1, and the low voltage winding 3 includes n identical winding units arranged in the axial direction, n≥ 3. Each winding unit is insulated from each other, each winding unit includes m split windings insulated from each other, m≥3, and the same split winding corresponding to each winding unit is connected in parallel, that is to say, in each winding unit The xth split winding of is connected in parallel with the xth split winding of the remaining n-1 winding units, 1≤x≤m. That is, the first split winding in each winding unit is connected in parallel with each first split winding in the remaining n-1 winding units, and the second split winding in ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com