Method of measuring and monitoring weight of UO2 pellets in single fuel rod in real time

A technology of fuel rods and pellets, applied in nuclear reactor monitoring, reactors, nuclear power generation, etc., can solve the problems of unable to monitor the fluctuation of fuel rod material consumption in time, unable to obtain the weight of pellets in time, and low degree of automation, etc., to achieve data The effects of tracing, improving the degree of weighing information, and simplifying the recording method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

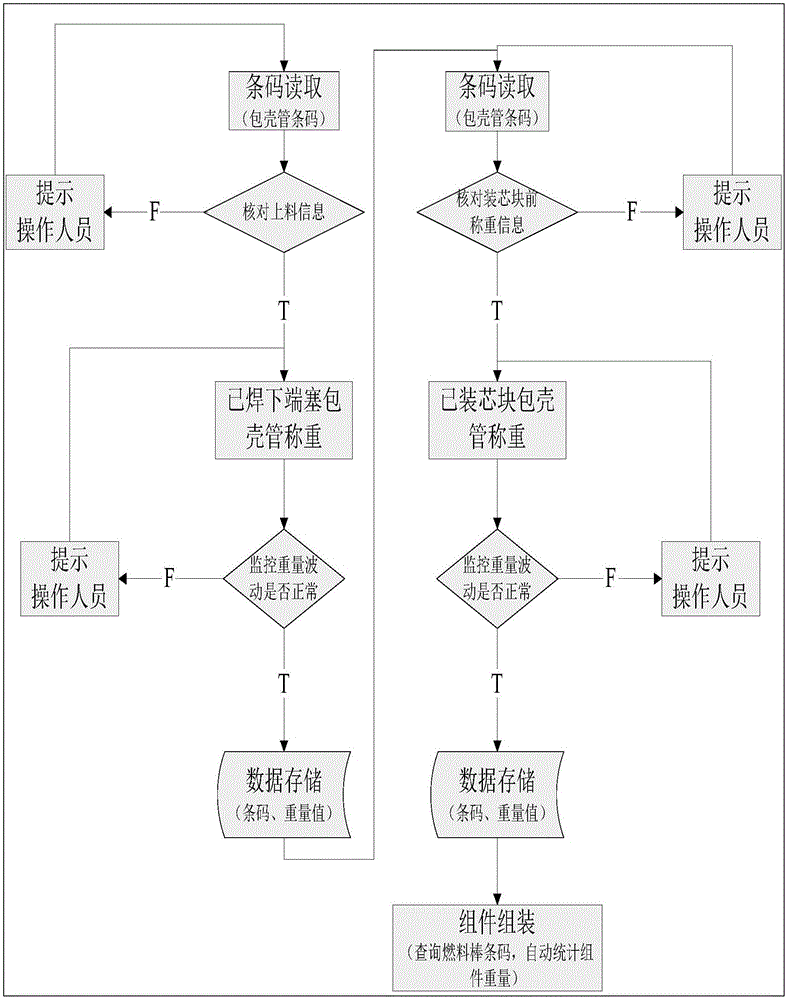

[0019] A real-time weighing and monitoring of UO in a single fuel rod according to the present invention is described below in conjunction with the accompanying drawings and specific embodiments. 2 The pellet weight method is described further.

[0020] Such as figure 1 As shown, a real-time weighing and monitoring UO in a single fuel rod according to the present invention 2 The method for pellet weight, it may further comprise the steps:

[0021] (1) After the cladding tube is welded to the lower end plug, it is sent to the weighing position. The barcode reading device automatically reads the barcode on the cladding tube and compares the welding information in the database to confirm whether the cladding tube has been welded;

[0022] (2) For step (1), it is determined that the cladding tube after welding is automatically weighed by the weighing system. After the weighing system obtains the weight value, it judges whether it is within the fluctuation limit range. If it is w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com