Dry recovery system and method of reduction tail gas produced in polysilicon production process

A dry recovery and production process technology, applied in the directions of hydrogen separation, using liquid contact hydrogen separation, using solid contact hydrogen separation, etc., can solve the problems of product quality decline, difficult maintenance, expensive bag filter, etc., and achieve simple molding. , the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

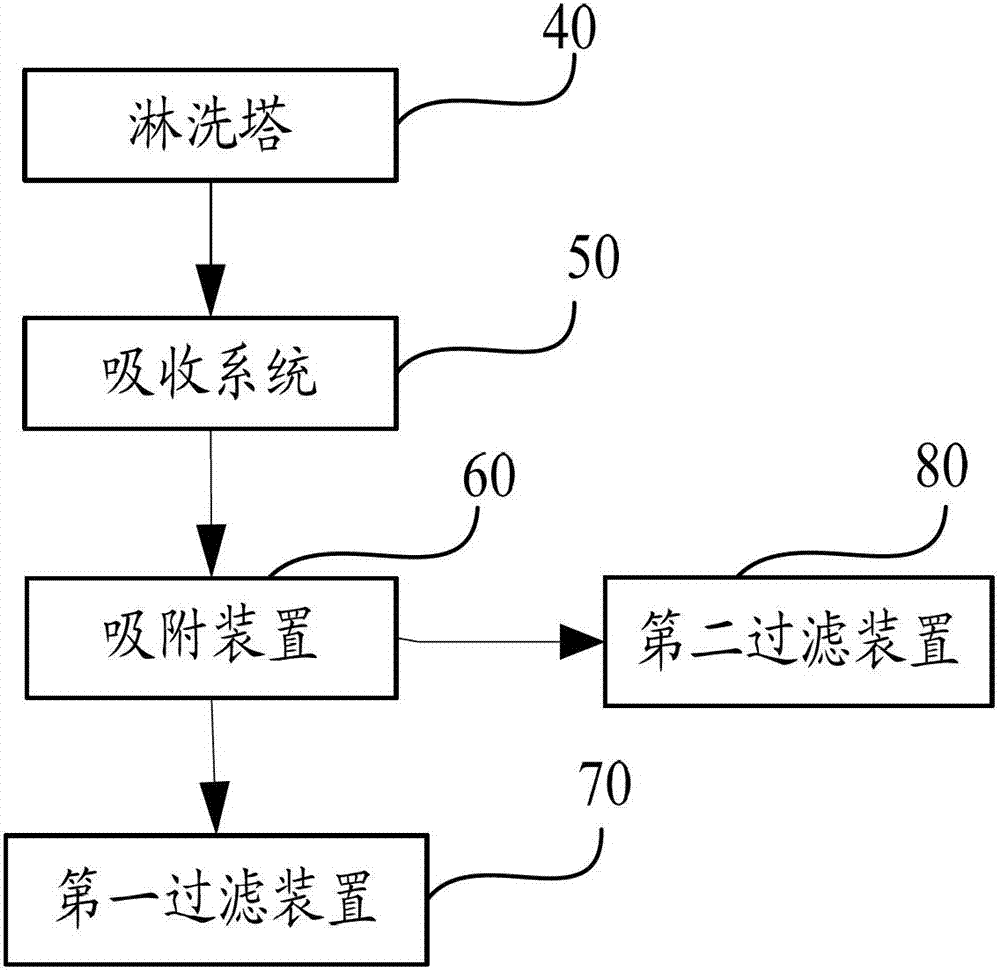

[0079] Such as Figure 6 As shown, firstly, the reduction tail gas is bubbled and washed through the washing tower 40 to remove the high-chlorosilane and solid impurities in the reduction tail gas. The components of the reduction tail gas are chlorosilane, hydrogen and a small amount of hydrogen chloride.

[0080] Pass the rinsed reduction tail gas into the absorption system 50 for absorption and desorption, so as to absorb the rinsed reduction tail gas, remove the chlorosilane and hydrogen chloride in it, and obtain hydrogen (which contains a trace amount of hydrogen chloride and a trace amount of chlorosilane). The absorbed chlorosilanes and hydrogen chloride can be further separated to obtain chlorosilanes and hydrogen chloride respectively. The separated chlorosilane can participate in the reduction reaction again after purification, and the reduction tail gas after the reaction is recovered through the dry recovery system again to form a recycling. The separated hydrogen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| filtration accuracy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com