Intelligent dense medium separation system and working method thereof

A sorting system and heavy medium technology, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve problems such as low efficiency of production systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

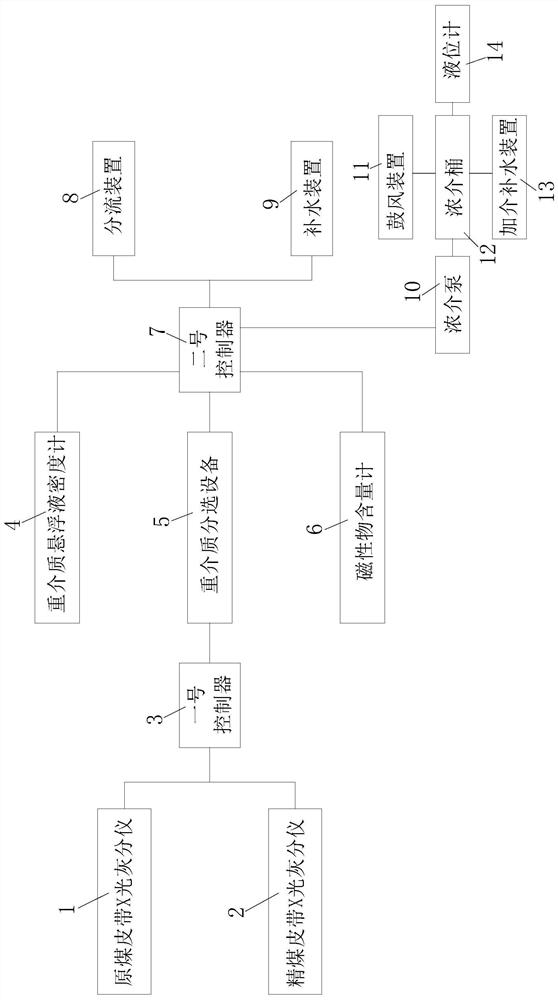

[0032] Example 1 (eg figure 1 shown).

[0033] The intelligent dense medium separation system in this embodiment is characterized in that it includes raw coal belt X-ray ash analyzer 1, clean coal belt X-ray ash analyzer 2, No. 1 controller 3, dense medium suspension density meter 4, dense medium Sorting equipment 5, magnetic substance content meter 6, No. 2 controller 7, diversion device 8, water replenishment device 9 and intermediation system, raw coal belt X-ray ash analyzer 1 and clean coal belt X-ray ash analyzer 2 are all connected with No. 1 controller connected to device 3, No. 1 controller 3 is connected to dense medium suspension density meter 4, dense medium separation equipment 5 and magnetic substance content meter 6, dense medium suspension liquid density meter 4, dense medium separation equipment 5 and magnetic substance content The gauges 6 are all connected to the No. 2 controller 7, and the No. 2 controller 7 is connected to the diversion device 8 and the w...

Embodiment 2

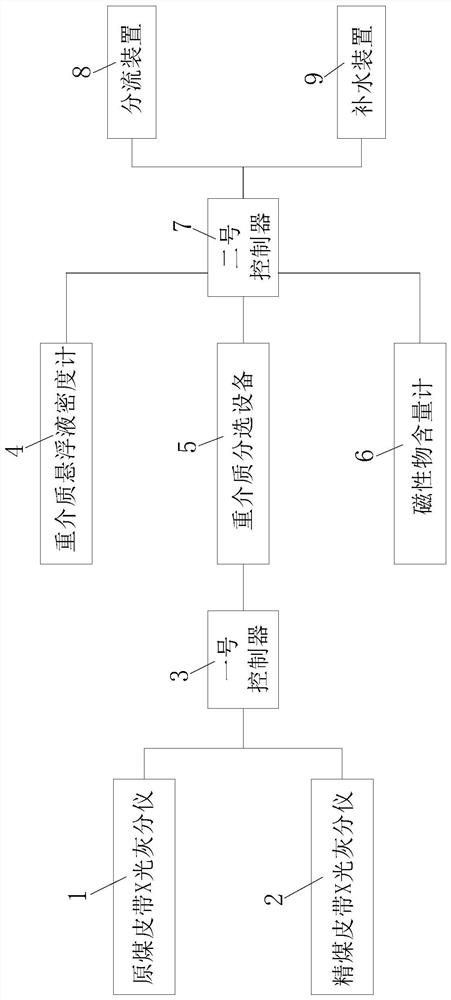

[0038] Example 2 (eg figure 2 shown).

[0039] The intelligent dense medium separation system in this embodiment is characterized in that it includes raw coal belt X-ray ash analyzer 1, clean coal belt X-ray ash analyzer 2, No. 1 controller 3, dense medium suspension density meter 4, dense medium Sorting equipment 5, magnetic substance content meter 6, No. 2 controller 7, diversion device 8 and water supply device 9, raw coal belt X-ray ash analyzer 1 and clean coal belt X-ray ash analyzer 2 are all connected to No. 1 controller 3, The No. 1 controller 3 is connected with the dense medium suspension density meter 4, the dense medium separation device 5 and the magnetic content meter 6, and the dense medium suspension density meter 4, the dense medium separation device 5 and the magnetic content meter 6 are all connected to the The No. 2 controller 7 is connected, and the No. 2 controller 7 is connected with the diversion device 8 and the water supply device 9 .

[0040] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com