Light environmental-friendly brick based on building waste and production process of light environmental-friendly brick

A technology of construction waste and production process, applied in the field of bricks and tiles, can solve the problems of unequal size of pores, poor foaming effect, affecting the use effect of products, etc., and achieve the effect of reducing internal stress and increasing structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

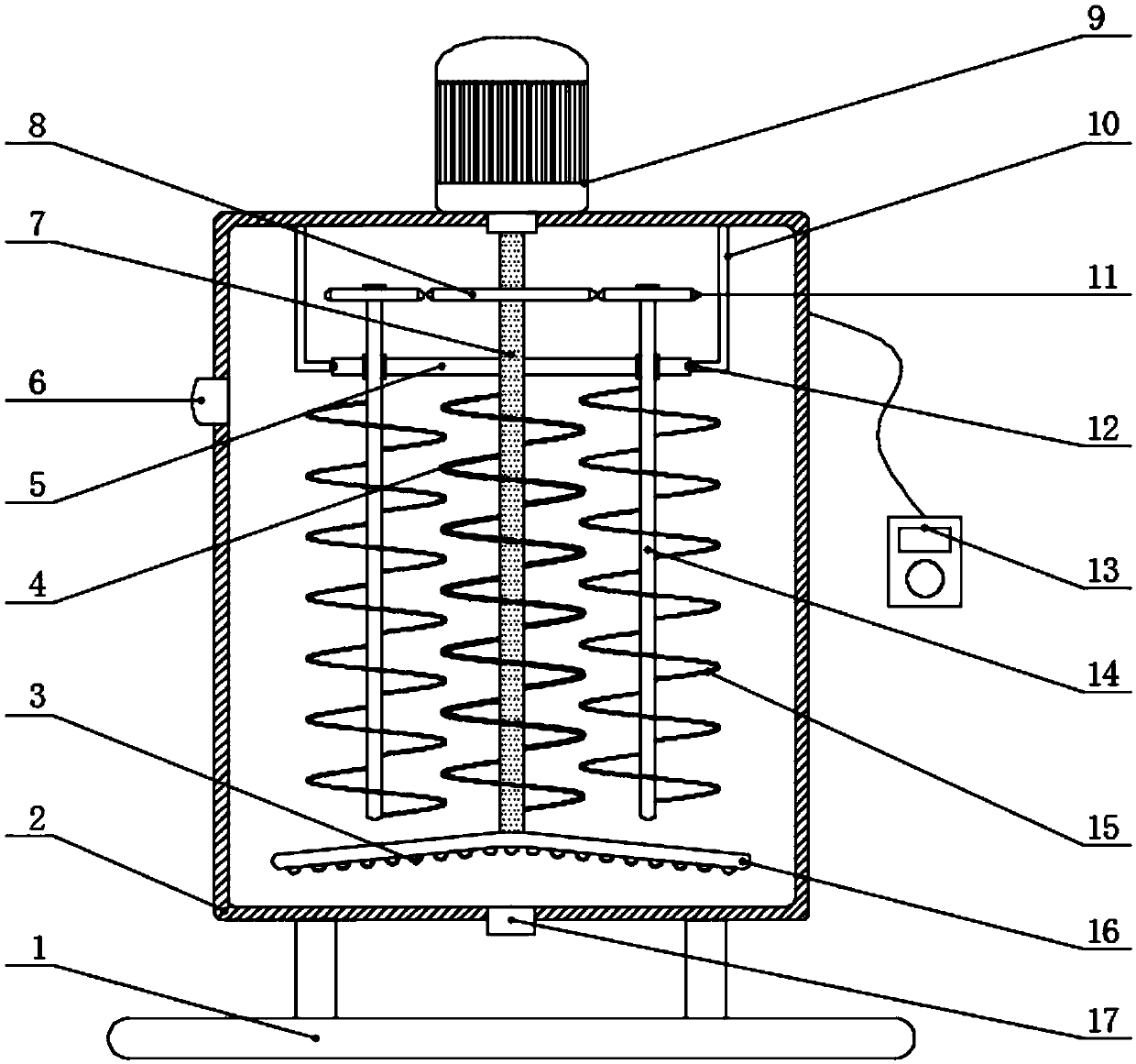

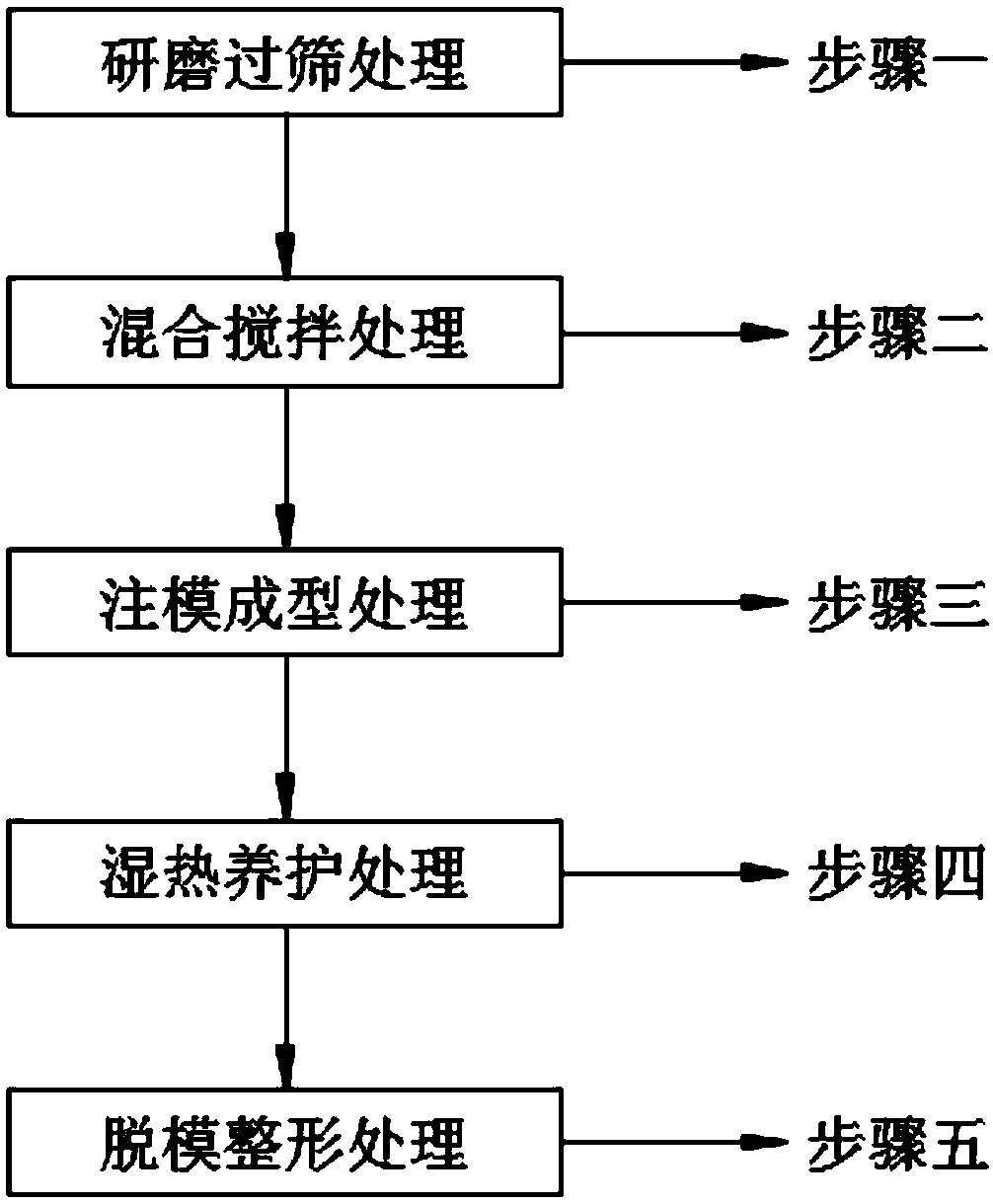

Method used

Image

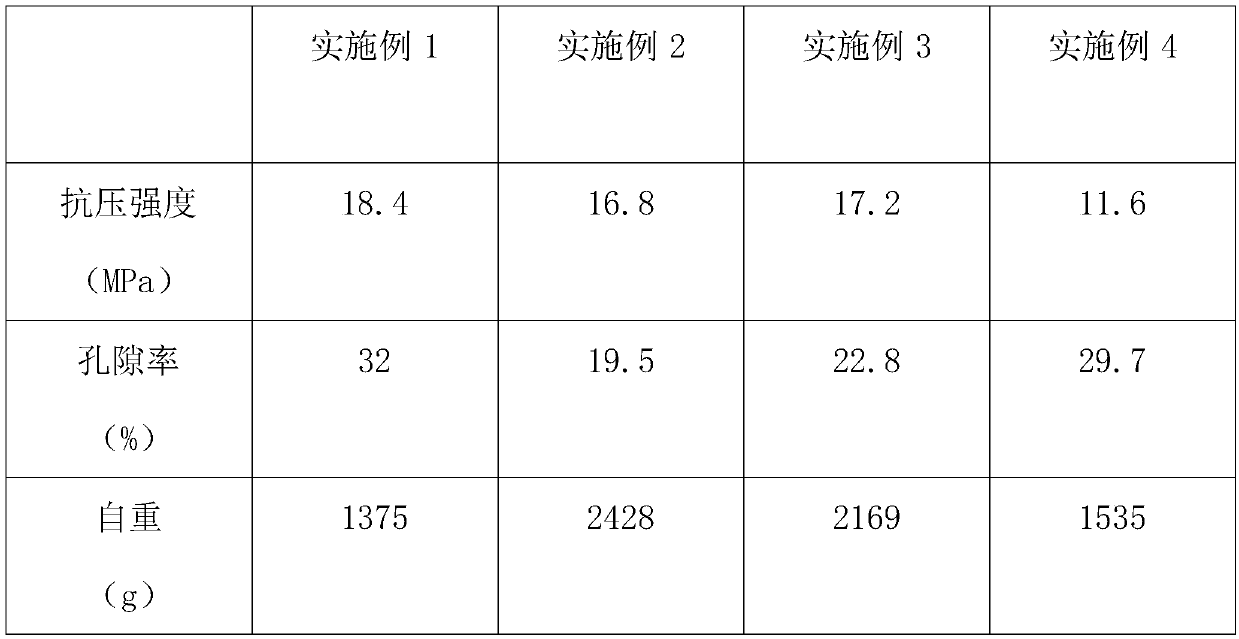

Examples

Embodiment 1

[0029] A light and environmentally friendly brick and tile based on construction waste. The raw materials are 40% water, 20% Portland cement, 10% ceramic waste, 10% brick waste, and 7% river sand by weight. , 5% wood chips, 5% slag and 3% modified foaming aid;

[0030] The modified foaming aid is prepared as follows: firstly, benzene and dodecene are introduced into the stirred tank and mixed for 15 minutes, then aluminum trichloride is added thereto, and the stirred tank is heated to 75 degrees at the same time, And react at constant temperature for 60 minutes at the same rotating speed, and then wash with alkali and water to recover benzene, then depressurize to 15kpa and rectify to obtain reaction solution A, and introduce the obtained reaction solution A into the sulfonation tank , and then add fuming sulfuric acid to it, make it react at a constant temperature of 45 degrees for 120 minutes to obtain the reaction solution B, then pass the reaction solution B into the react...

Embodiment 2

[0039] A light-weight environment-friendly brick and tile based on construction waste, the same as in Example 1.

[0040] The modified foaming aid is prepared as follows: firstly, benzene and dodecene are introduced into the stirred tank and mixed for 15 minutes, then aluminum trichloride is added thereto, and the stirred tank is heated to 75 degrees at the same time, And react at constant temperature for 60 minutes at the same rotating speed, and then wash with alkali and water to recover benzene, then depressurize to 15kpa and rectify to obtain reaction solution A, and introduce the obtained reaction solution A into the sulfonation tank , then add fuming sulfuric acid to it, make it react at a constant temperature of 45 degrees for 120 minutes, to obtain the reaction solution B, then pass the reaction solution B into the reaction kettle whose solvent is ethanol solution, and then add sodium hydroxide solution therein , and keep the pH value in the reactor at 7-8, then react ...

Embodiment 3

[0044] A light-weight environment-friendly brick and tile based on construction waste, the same as in Example 1.

[0045] The modified foaming aid is prepared as follows: firstly introduce benzene and dodecene together into the stirring tank and mix and stir for 15 minutes, then add aluminum trichloride to it, and simultaneously raise the temperature of the stirring tank to 75 degrees, And react at constant temperature for 60 minutes at the same rotating speed, and then wash with alkali and water to recover benzene, then depressurize to 15kpa and rectify to obtain reaction solution A, and introduce the obtained reaction solution A into the sulfonation tank , then add fuming sulfuric acid to it, make it react at a constant temperature of 45 degrees for 120 minutes to obtain the reaction solution B, then pass the reaction solution B into the reaction kettle whose solvent is ethanol solution, and then add calcium hydroxide to it successively solution and sodium hydroxide solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com