Energy-saving and yield-improving production method of ethyl acetate

A production method, the technology of ethyl acetate, which is applied in the field of energy-saving and production-increasing ethyl acetate, can solve the problems that cannot be improved, and the product energy consumption cannot be further effectively reduced, so as to reduce the operating load, reduce the return flow, and reduce equipment corrosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

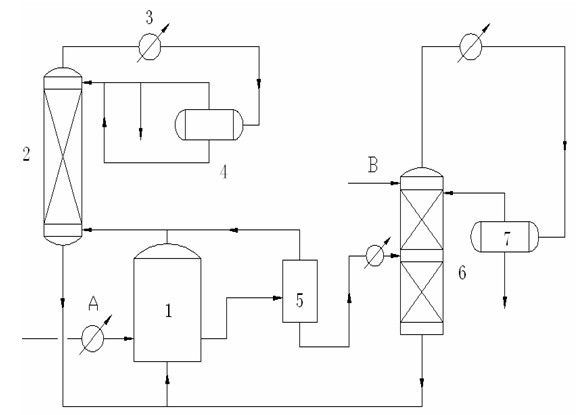

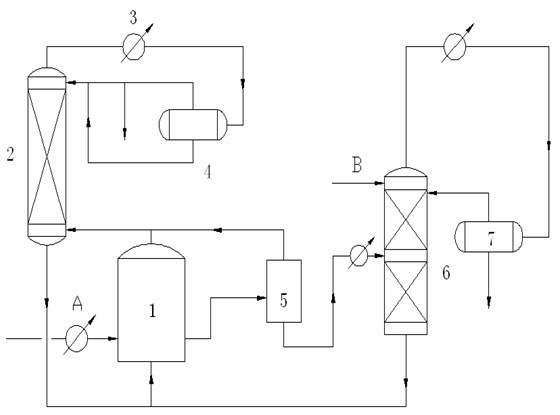

[0016] like figure 1 As shown, the modified device in this workshop adopts continuous feeding, and the raw materials acetic acid and alcohol are added at a molar ratio of 1:1, and the catalyst concentrated sulfuric acid is directly added to the reaction kettle 1 in a certain amount. The esterification reaction is carried out inside, and the product after the reaction undergoes azeotropic distillation, and the azeotrope enters the esterification tower 2 in binary and ternary forms for separation, and the overhead distillate is condensed by the esterification condenser 3, and the ester-water phase device 4 After phase separation, the crude product can be obtained, a part of which is returned to the esterification tower 2 for reflux, and the other part is subjected to subsequent enrichment and rectification to obtain the finished product ethyl acetate.

[0017] The bottom material in the reaction kettle 2 is extracted according to twice the total amount of the feed, and is transp...

Embodiment 2

[0021] The process of each section of the esterification reaction is the same as implementation 1, such as figure 1 As shown, the bottom material in the reactor 2 is withdrawn according to twice the feed amount, and is transported to the flash tank 5 by a pump for a flash evaporation. The flash temperature is controlled at 110-130°C, and the flash pressure is controlled at 0.15-0.25Mpa. After flashing, most of the esters and alcohols in the bottom material return to the bottom of the esterification tower 2, and the remaining bottom material ester phase is a large amount of acid and part of water, which is discharged from the bottom of the flash tank through a pump. In the treated bottom material, the component water is about 6.5%, and the component acetic acid is about 92.2%.

[0022] The treated bottom material is pumped to the heat exchanger for heating, and then directly enters the dehydration tower 6 for dehydration treatment. The dehydrating agent is isobutyl acetate, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com