Cement kiln cooperative processing domestic garbage power generation system and method

A power generation system and co-processing technology, applied in combustion methods, machines/engines, lighting and heating equipment, etc., can solve problems such as low processing capacity, and achieve the effect of saving operating costs, stable state, and small impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

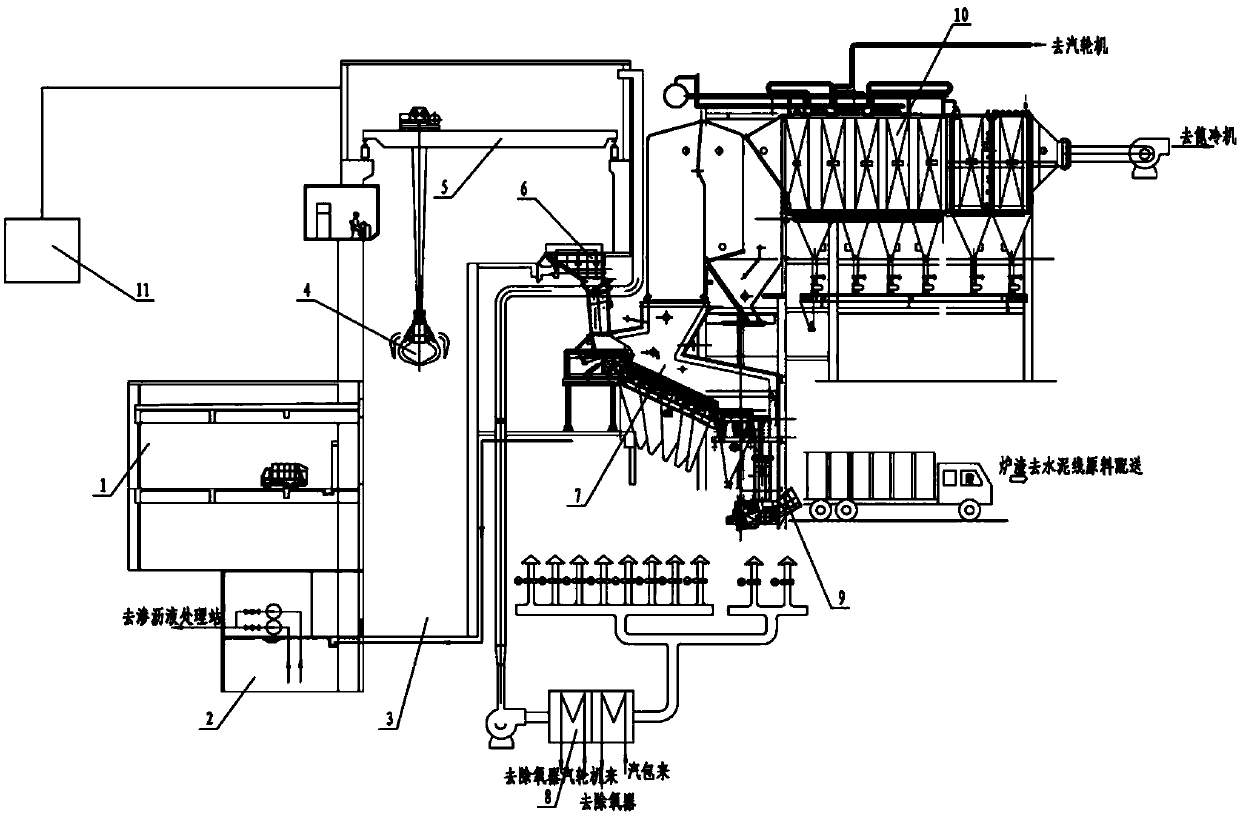

[0029] Further description will be given below in conjunction with the accompanying drawings and embodiments.

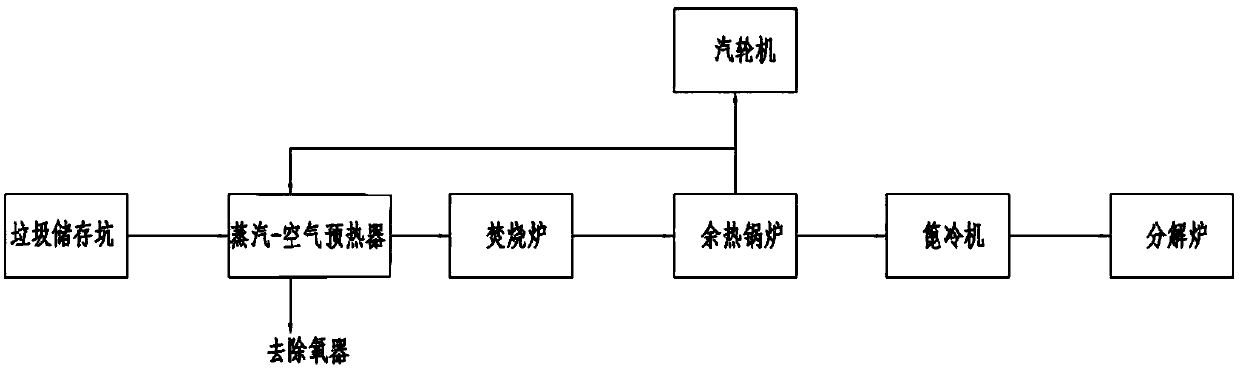

[0030] A power generation system for co-processing domestic waste with cement kilns in this embodiment includes a waste receiving and storage system, an incineration system, a leachate treatment system, an odor treatment system, a waste heat boiler system, a turbine power generation system, and a flue gas purification system. The invention combines cement production, garbage disposal and garbage power generation to form a brand-new garbage disposal technology, which not only has the advantages of the traditional garbage incineration method, but also solves the problem of dioxin and garbage. The problem of ash handling.

[0031] The receiving and storage system includes an unloading hall 1, a garbage storage pit 3 and a feeding device 6; a garbage truck 5 and a grab 4 are arranged above the garbage storage pit 3, and the grab 4 sends the garbage to the feeding device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com