Chopped carbon fiber preform processing method using coal tar pitch binder

a carbon fiber and preform technology, applied in the direction of metallic material coating process, chemical vapor deposition coating, building components, etc., can solve the problems of undeveloped commercially attractive substitutes for coal tar pitch in the aluminum industry, the decomposition of coal tar pitch, and the formation of unwanted mesophase pitch, etc., to achieve high softening, reduce volatile yield, and high softening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

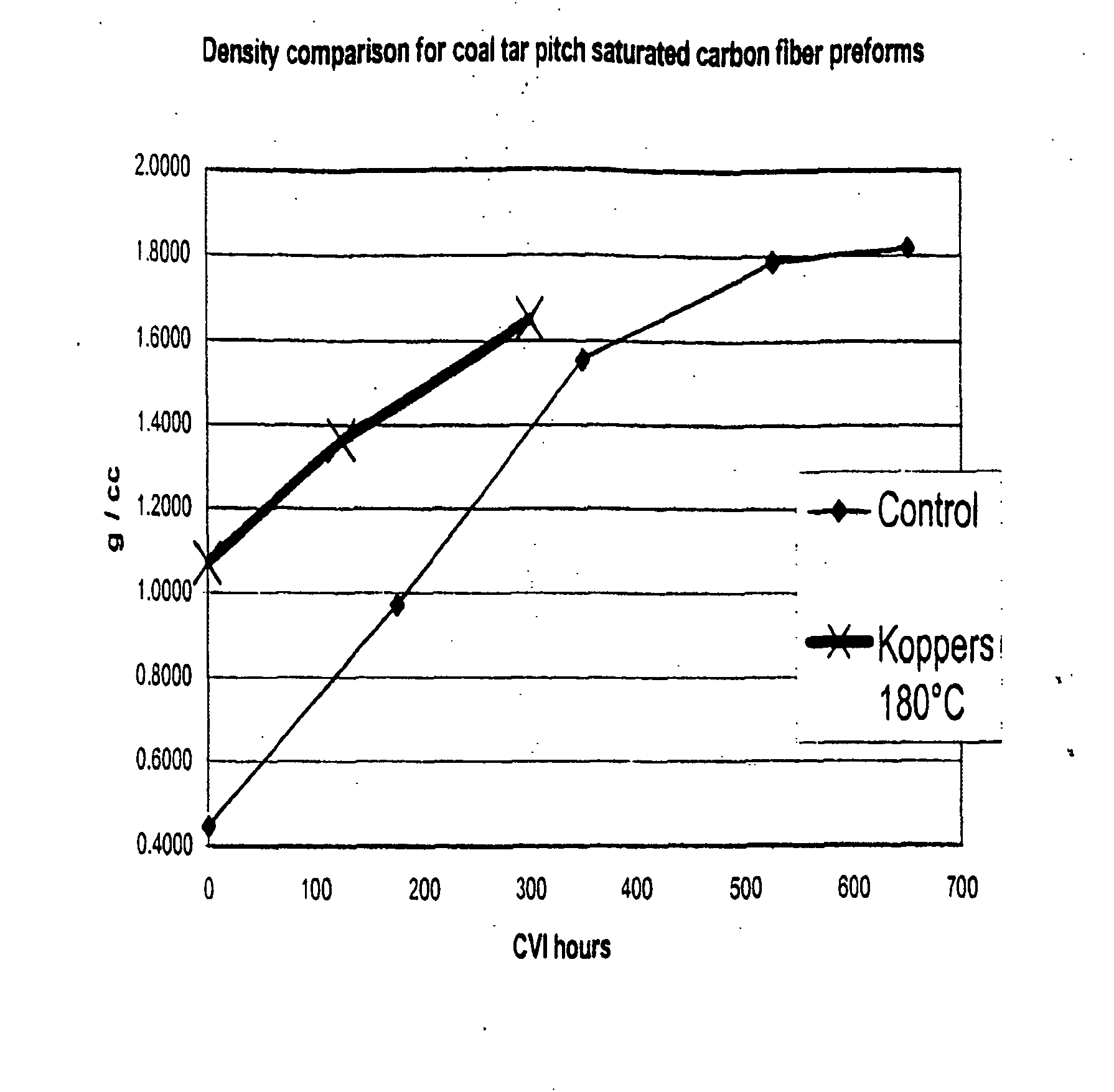

example 1

[0040] A feed coal tar pitch having, a softening point of 109° C. is fed into a WFE apparatus having a 1.4 square foot vessel operating at a temperature of 335° C., 18.5 mmHg absolute, and at a feed rate of 77 pounds / square foot of surface area / hour. The output coal tar pitch of the WFE apparatus has a pitch yield of 85%. A laboratory analysis of the output coal tar pitch is summarized in the following Table II:

TABLE IISoftening Point, ° C.140.6Toluene Insolubles, wt. %32.9Quinoline Insolubles, wt. %15.1Coking Value, Modified64.9Conradson, wt. %Ash, wt. %0.20Specific Gravity, 25 / 25° C.1.35Beta Resin, wt. %17.8

example 2

[0041] A feed coal tar pitch having a softening point of 109° C. is fed into a WFE apparatus having a 1.4 square foot vessel operating at a temperature of 335° C., 10.4 mmHg absolute, and at a feed rate of 95 pounds / square foot / hour. The output coal tar pitch of the WFE apparatus has a pitch yield of 73%. A laboratory analysis of the output coal tar pitch is summarized in the following Table III:

TABLE IIISoftening Point, ° C.163.0Toluene Insolubles, wt. %37.7Quinoline Insolubles, wt. %17.0Coking Value, Modified71.6Conradson, wt. %Ash, wt. %0.22Specific Gravity, 25 / 25° C.1.36Beta Resin, wt. %20.7

example 3

[0042] A feed coal tar pitch having a softening point of 109° C. is fed a WFE apparatus having a 1.4 square foot vessel operating at a temperature of 350° C., 5.0 mmHg absolute and at a feed rate of 65 pounds / square foot / hour. The output coal tar pitch of the WFE apparatus has a pitch yield of 74.2%. A laboratory analysis of the output coal tar pitch is summarized in the following Table IV:

TABLE IVSoftening Point, ° C.200.0Toluene Insolubles, wt. %42.2Quinoline Insolubles, wt. %18.2Coking Value, Modified76.5Conradson, wt. %Ash, wt. %0.27Specific Gravity, 25 / 25° C.1.378Beta Resin, wt. %24.1

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com