Turbulent mesophase pitch process and products

A technology of mesophase pitch and pitch, applied in the field of formation of mesophase pitch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

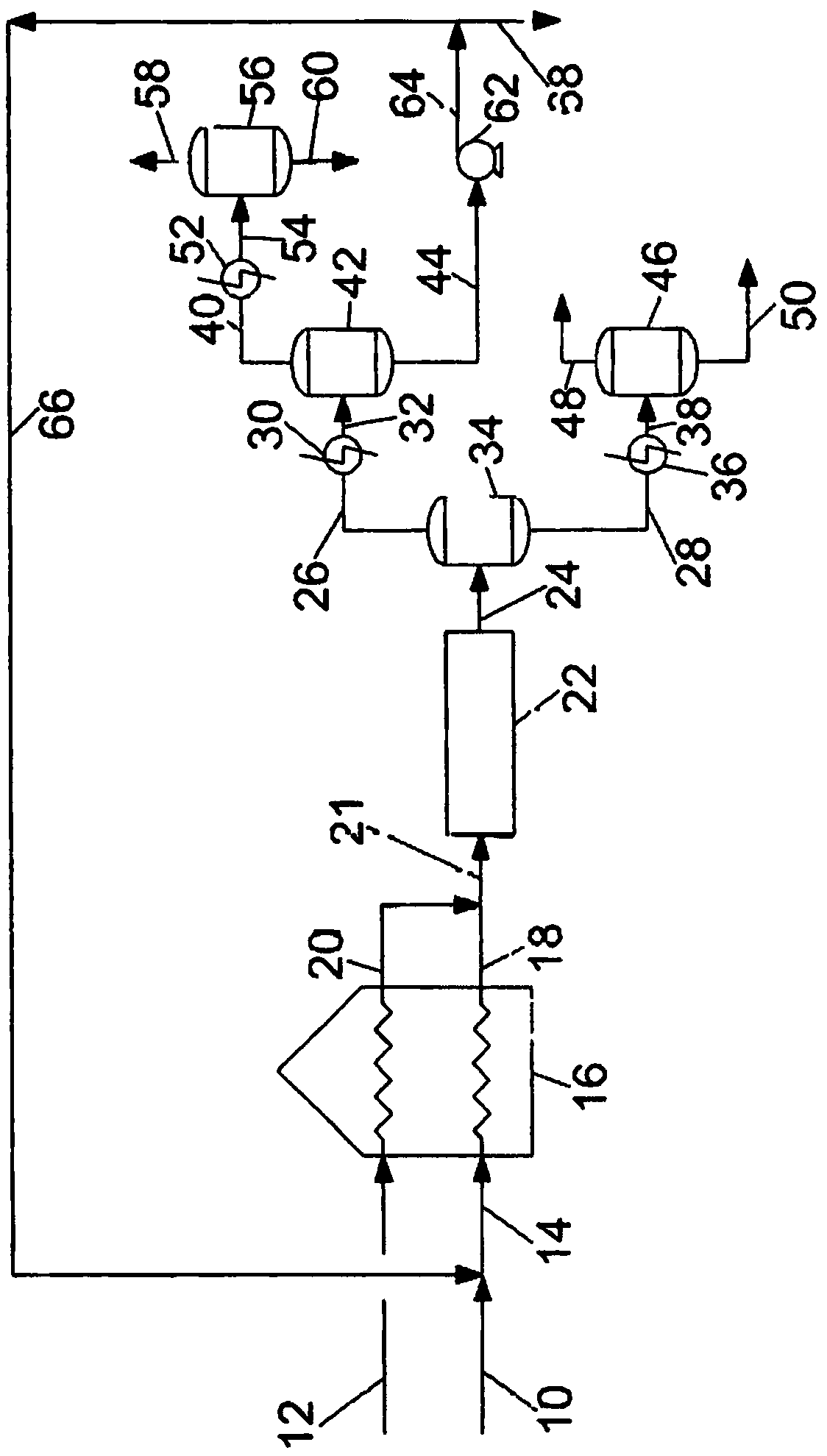

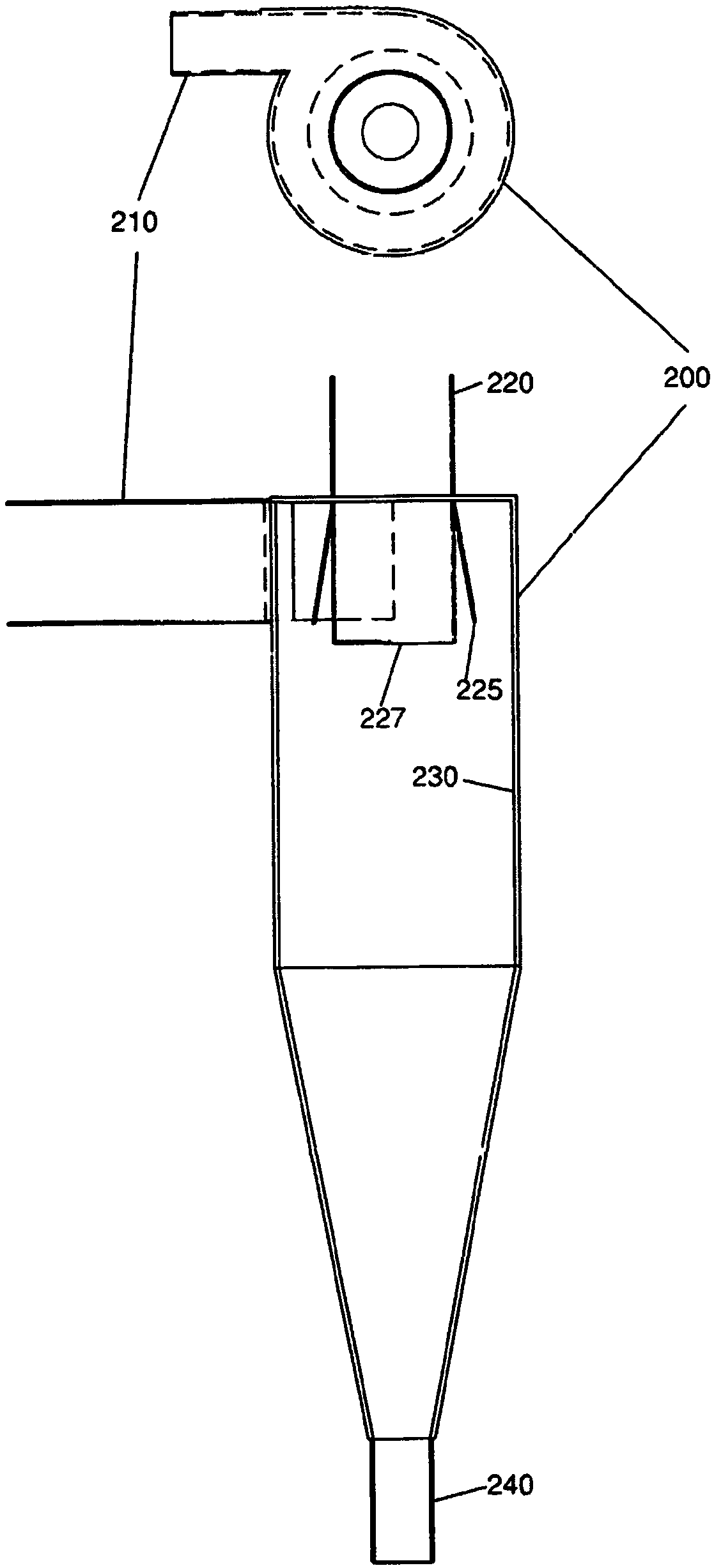

Method used

Image

Examples

Embodiment

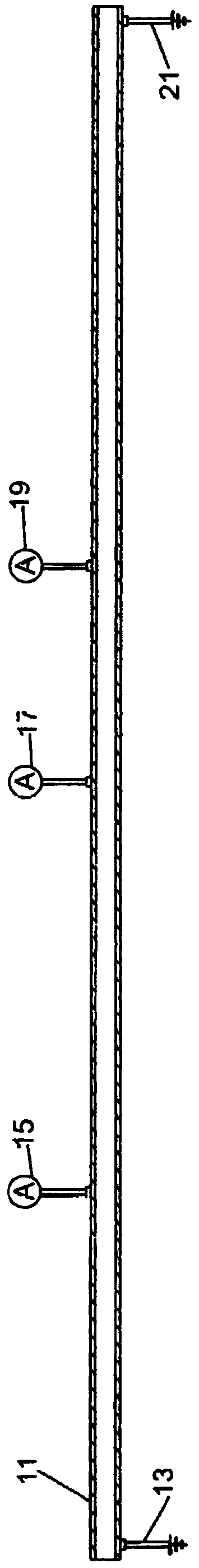

[0089] Applicant used 9.52 mm (3 / 8") outside diameter (OD) pipe 15.24 m (50 ft) long with a 0.711 mm (0.028") wall thickness fabricated from Type 316L stainless steel (ss), Type 316L stainless steel was heated by a Miller 300CP welder to pass an electrical current through the reactor tubes for the applicant's experimental studies. The results shown in the table below were produced over a continuous 30-hour operating cycle. The residue and overhead were drawn off every 2 hours. Softening point and primary coke value analyzes were performed on samples of these effluents.

[0090]

[0091] For all tests, the superheated steam feed rate was approximately equal to the bitumen feed rate. The staging unit was shut down in good working order after processing 146.9 kg of M-50 bitumen as feed. This means that the average thickness of coke deposited on the inner wall of the tube is less than 0.0254 mm (0.001 inch), or the pressure drop in the tube will become an unacceptable pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com