A chemical reaction modified asphalt profile control water blocking agent and its preparation method and application

A technology of profile control water blocking agent and modified asphalt, which is applied in chemical instruments and methods, processing tar asphalt/petroleum asphalt/natural asphalt, tar asphalt/petroleum asphalt/natural asphalt, etc., can solve the problem of anti-corrosion Problems such as weak high-temperature resistance, strong specificity, and poor injectability have achieved significant technical effects and application potential effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

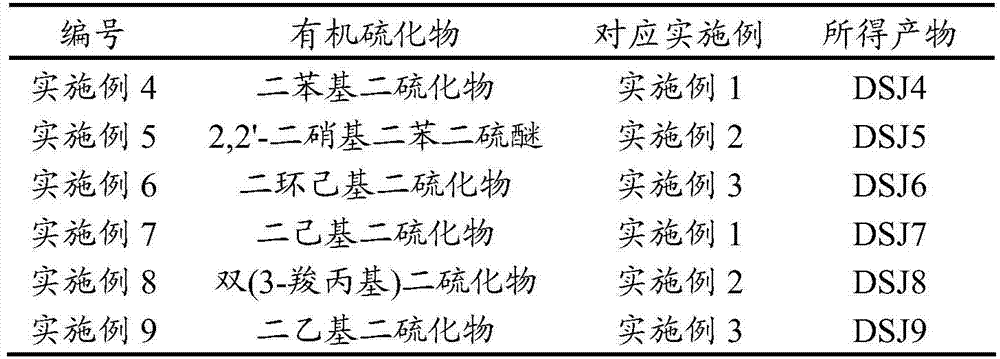

Examples

Embodiment 1

[0050] S1: Vulcanizing and modifying petroleum asphalt to obtain vulcanized modified petroleum asphalt, which includes the following steps:

[0051] S1-1: Add petroleum asphalt to an appropriate amount of heptane, stir thoroughly for 20 minutes to dissolve completely, and then filter to remove insoluble matter to obtain asphalt solution;

[0052] S1-2: Add bis(2,3-xylyl) disulfide, an organic sulfide, to the asphalt solution, react under closed stirring at 50°C for 6 hours, then cool naturally to room temperature, and completely volatilize the heptane, Thereby obtain described vulcanized modified petroleum asphalt;

[0053] Wherein, the mass ratio of the petroleum pitch in step S1-1 to the organic sulfide in step S1-2 is 1:0.05.

[0054] S2: Carry out cationic modification to petroleum asphalt to obtain cationic modified petroleum asphalt. This step is specifically as follows:

[0055] Add petroleum asphalt to an appropriate amount of trichlorethylene, stir fully to dissolve...

Embodiment 2

[0060] S1: Vulcanizing and modifying petroleum asphalt to obtain vulcanized modified petroleum asphalt, which includes the following steps:

[0061] S1-1: Add petroleum asphalt to an appropriate amount of heptane, stir thoroughly for 30 minutes to dissolve completely, and then filter to remove insoluble matter to obtain asphalt solution;

[0062] S1-2: Add bis(2,3-xylyl) disulfide, an organic sulfide, to the asphalt solution, react under closed stirring at 60°C for 5 hours, then cool naturally to room temperature, and completely volatilize the heptane, Thereby obtain described vulcanized modified petroleum asphalt;

[0063] Wherein, the mass ratio of the petroleum pitch in step S1-1 to the organic sulfide in step S1-2 is 1:0.07.

[0064] S2: Carry out cationic modification to petroleum asphalt to obtain cationic modified petroleum asphalt. This step is specifically as follows:

[0065] Add petroleum asphalt to an appropriate amount of trichlorethylene, stir to dissolve compl...

Embodiment 3

[0070] S1: Vulcanizing and modifying petroleum asphalt to obtain vulcanized modified petroleum asphalt, which includes the following steps:

[0071] S1-1: Add petroleum asphalt to an appropriate amount of heptane, stir thoroughly for 40 minutes to dissolve completely, and then filter to remove insoluble matter to obtain asphalt solution;

[0072] S1-2: Add organic sulfide bis(2,3-xylyl) disulfide to the asphalt solution, and react under closed stirring at 70°C for 4 hours, then cool naturally to room temperature, and completely volatilize the heptane, Thereby obtain described vulcanized modified petroleum asphalt;

[0073] Wherein, the mass ratio of the petroleum pitch in step S1-1 to the organic sulfide in step S1-2 is 1:0.1.

[0074] S2: Carry out cationic modification to petroleum asphalt to obtain cationic modified petroleum asphalt. This step is specifically as follows:

[0075]Add petroleum asphalt to an appropriate amount of trichlorethylene, stir to dissolve complete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com