High Quality Asphalt Containing Pitch and Method of Preparing the Same

a technology of high-quality asphalt and containing wax, which is applied in the direction of working-up pitch/asphalt/bitumen by mixing fractions, hydrocarbon oil treatment, etc., can solve the problems of low yield upon operation of vacuum distillation unit to ensure the quality of asphalt, low quality of relatively expensive vacuum gas oil, etc., and achieves superior wax content and ductility. , the effect of high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

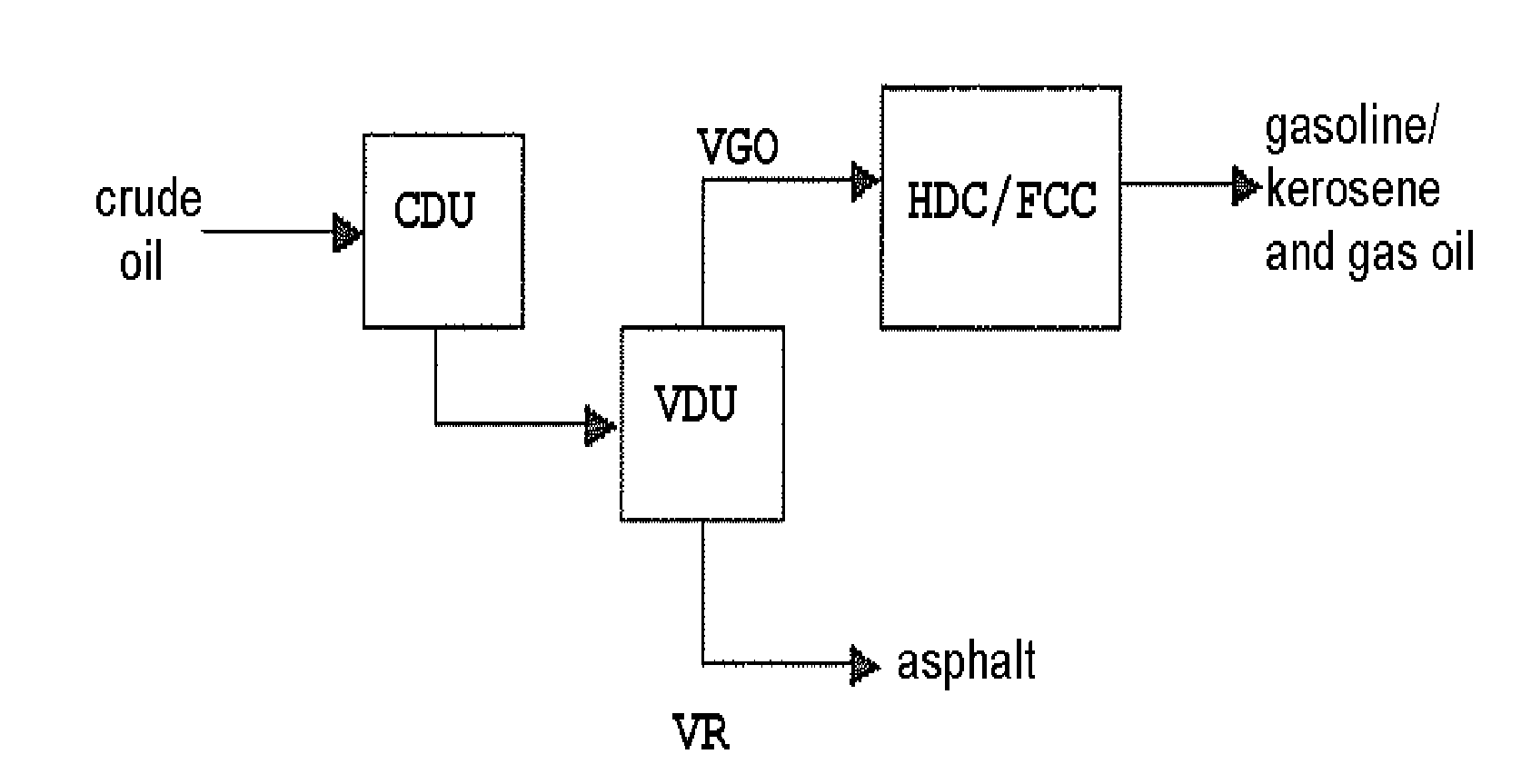

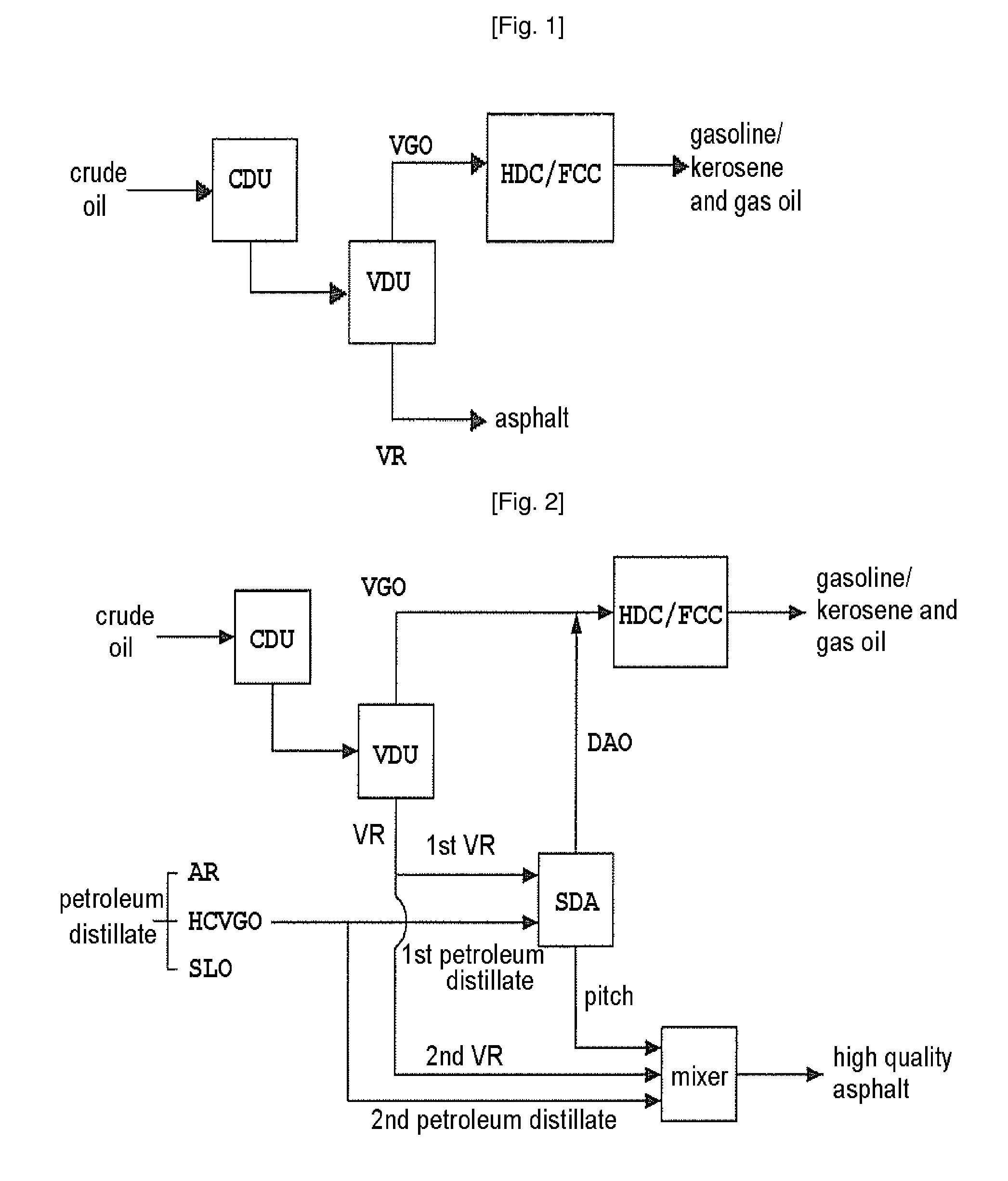

Problems solved by technology

Method used

Image

Examples

example 1

[0027]A feedstock comprising the atmospheric residue (AR) and the vacuum residue (VR) having the properties shown in Table 1, mixed at a volume ratio of 18:11, was subjected to solvent deasphalting under the conditions shown in Table 2 below, thus producing deasphalted oil and pitch. The results are shown in Table 3 below. In order to control the penetration of the pitch thus obtained, a heart cut vacuum residue was further added, leading to asphalt. The properties of the asphalt thus obtained are shown in Table 4 below.

[0028]As is apparent from Table 4, in the case where the asphalt was prepared using the pitch, it had higher amounts of aromatic and resin and a lower amount of saturate than those of conventional asphalt obtained from the vacuum residue produced using a vacuum distillation unit, and thus high quality asphalt having low wax content and high ductility after a thin film oven test could be produced. Since the penetration of the asphalt was lower by about 6 than that of ...

example 2

[0029]A feedstock comprising the atmospheric residue and the vacuum residue having the properties shown in Table 1, mixed at a volume ratio of 18:11, was subjected to solvent deasphalting under the conditions shown in Table 5 below, thus obtaining deasphalted oil and pitch. The results are given in Table 6 below. The pitch thus obtained was mixed with the vacuum residue and then with the heart cut vacuum residue to control the penetration thereof, leading to asphalt. The properties of the asphalt thus obtained are shown in Table 7 below.

[0030]As is apparent from Table 7, the asphalt prepared using the pitch was confirmed to have ductility after a thin film oven test that was superior to that of asphalt produced from the vacuum residue under the same penetration conditions.

TABLE 5Conditions of Solvent Deasphalting: 70% PitchFeedAR / VR (18 / 11 vol.)SolventPropanePitch Yield, wt %70Pressure, kg / cm2g45.7Temp. of Asphaltene Separator, ° C.88

TABLE 6Feed of Solvent Deasphalting and Propertie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com