Process for preparing needle coke from medium-low temperature coal tar pitch by four-stage variable-temperature refining one-step method

A technology for low-temperature coal tar and kerosene pitch, which is used in the processing of tar pitch/petroleum pitch/natural pitch, processing tar pitch/petroleum pitch/natural pitch by distillation, and tar processing by distillation, etc. The problems of blending and heat-reactive substances are difficult to remove, so as to achieve the effects of uniform blending ratio, low production cost and good blending effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

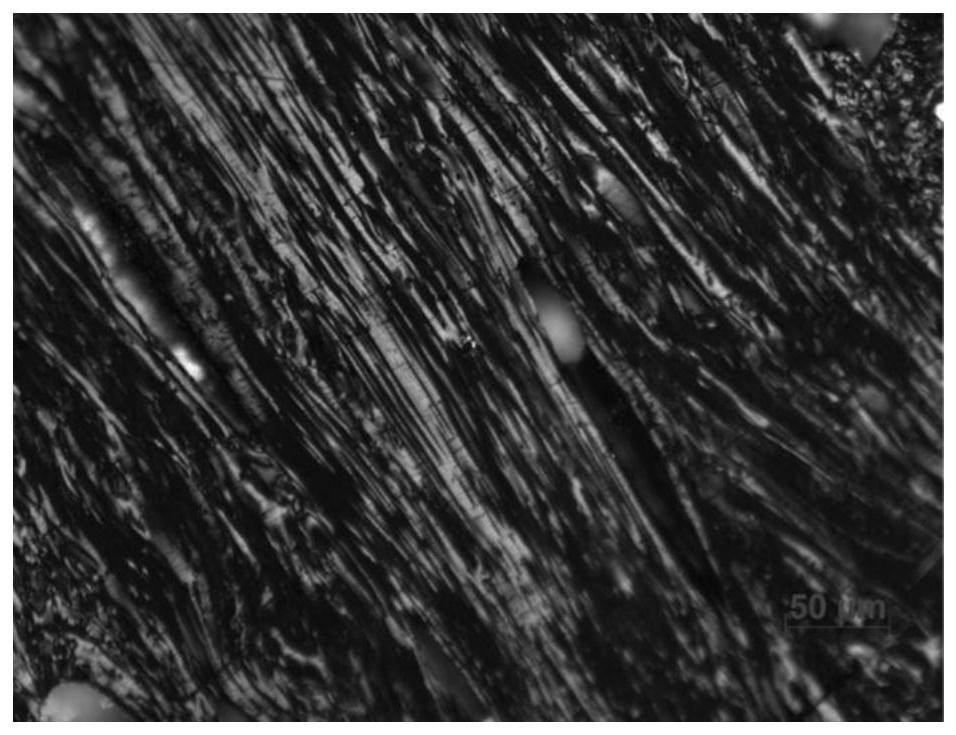

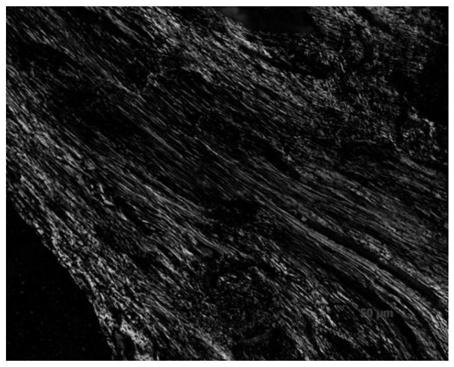

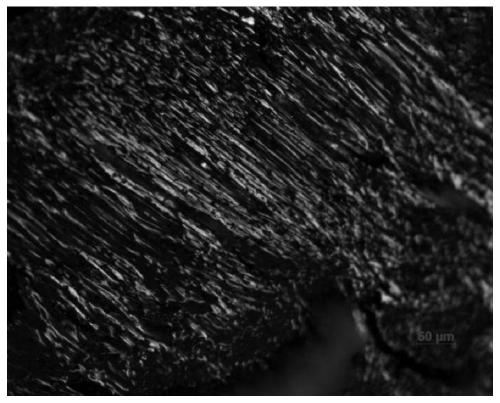

Embodiment 1

[0052] Put 2kg of medium and low temperature coal tar in the rectification reaction kettle, carry out vacuum distillation, distill out the medium and low temperature kerosene pitch in the fraction of 400-480°C, take 100g of medium and low temperature kerosene pitch for crushing; give the crushed Add a blending agent of 400wt% of the medium and low temperature kerosene pitch to the medium and low temperature kerosene pitch to reconcile the components of the medium and low temperature kerosene pitch; raise the temperature to 60°C; then raise the temperature to 100°C, stand at constant temperature for 5 hours, extract and enrich the raw material aromatics, Discharge the macromolecular impurities insoluble in the extractant from the bottom of the reaction kettle; add a modifier, the amount of the modifier added is 0.2%wt of the weight of the medium and low temperature kerosene pitch, continue to heat up to 150 ° C, keep it at a constant temperature for 4 hours, use The modifier rea...

Embodiment 2

[0055] Put 2kg of medium and low temperature coal tar in the rectification reaction kettle, carry out vacuum distillation, distill out the medium and low temperature kerosene pitch in the fraction of 400-480°C, take 100g of medium and low temperature kerosene pitch for crushing; give the crushed Add a blending agent of 300wt% of the medium and low temperature kerosene pitch to the medium and low temperature kerosene pitch to adjust the composition of the medium and low temperature kerosene pitch; raise the temperature to 60°C; then raise the temperature to 100°C, stand at constant temperature for 5 hours, extract and enrich the raw material aromatics, Discharge the macromolecular impurities insoluble in the extractant from the bottom of the reaction kettle; add a modifier, the amount of the modifier added is 0.2%wt of the weight of the medium and low temperature kerosene pitch, continue to heat up to 150 ° C, keep it at a constant temperature for 4 hours, use The modifier react...

Embodiment 3

[0058] Put 2 kg of medium and low temperature coal tar in the rectification reactor, carry out vacuum distillation, distill out the medium and low temperature kerosene pitch in the 360-480°C fraction, take 100g of medium and low temperature kerosene pitch for crushing; give the crushed Add a blending agent of 400wt% of the medium and low temperature kerosene pitch to the medium and low temperature kerosene pitch to reconcile the components of the medium and low temperature kerosene pitch; raise the temperature to 50°C; then raise the temperature to 120°C, stand at constant temperature for 8 hours, extract and enrich the raw material aromatics, The macromolecular impurities insoluble in the extractant are discharged from the bottom of the reaction kettle; the modifier is added in an amount of 0.3%wt of the weight of the medium and low temperature kerosene asphalt, and the temperature is continued to rise to 160°C, and the temperature is kept for 8 hours. The modifier reacts with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com