Preparation method for slurry oil mixed asphalt

An oil slurry and blending technology, which is applied in the processing of tar pitch/petroleum pitch/natural pitch, processing tar pitch/petroleum pitch/natural pitch by mixed fractions, petroleum industry, etc. Stability and other problems, to achieve the effect of improving oil slurry properties, high penetration ratio, and improving anti-aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Using the FY-Ⅲ true boiling point distillation unit produced by Fushun Petrochemical Research Institute, distill the catalytic cracking oil slurry of Shengli Oil Refinery of Qilu Branch to obtain oil slurry S1 at >430°C.

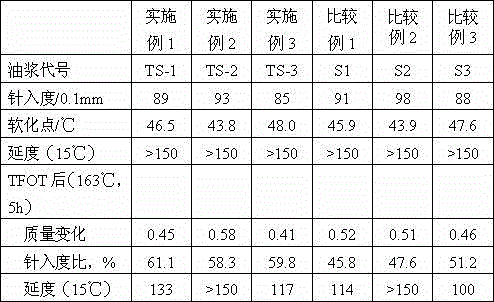

[0027] Heat the oil slurry at >420°C to 150°C and keep it at 150±5°C, add 5% (accounting for the weight of the slurry) of tertiary dodecyl mercaptan (Aladdin Reagent Company), and stir for 45 minutes to obtain modified oil pulp TS-1. Add 30% TS-1 to 145°C Tahe residual oil (penetration 40 1 / 10mm) and stir for 45 minutes to obtain blended pitch. The properties of the blended pitch are shown in Table 1.

Embodiment 2

[0029] Using the FY-Ⅲ real boiling point distillation device produced by Fushun Petrochemical Research Institute, distill the catalytic cracking oil slurry of Jingmen Branch to obtain oil slurry S2 at >420 °C.

[0030] Heat the oil slurry at >420°C to 130°C and keep it at 130±5°C, add 1% (accounting for the weight of the oil slurry) cyclohexanethiol (Aladdin Reagent Company), and stir for 30 minutes to obtain the modified oil slurry TS- 2. Add 40% of TS-2 to 145°C Jingmen dissolved deasphalt (penetration 15 1 / 10mm) and stir for 30 minutes to obtain blended pitch. The properties of the blended pitch are shown in Table 1.

Embodiment 3

[0032] Using the FY-Ⅲ true boiling point distillation device produced by Fushun Petrochemical Research Institute, the catalytic cracking oil slurry of Jiujiang Branch Company was distilled to obtain oil slurry S3 at >420 °C.

[0033] Heat the oil slurry at >420°C to 130°C and keep it at 130±5°C, add 3% (accounting for the weight of the slurry) of thiophenol (Aladdin Reagent Company) and stir for 60 minutes to obtain the modified oil slurry TS-3. Add 10% TS-3 to Tahe No. 60 asphalt at 145°C (penetration 55 1 / 10mm), and stir for 30 minutes to obtain a blended asphalt. The properties of the blended asphalt are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com