Method for recycling waste FCC (fluid catalytic cracking) catalyst

A waste catalyst and catalyst technology, applied in chemical instruments and methods, removal of solid waste, chemical processing of tar asphalt/petroleum asphalt/natural asphalt, etc., can solve problems such as application limitations, improve compatibility, improve The effect of high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

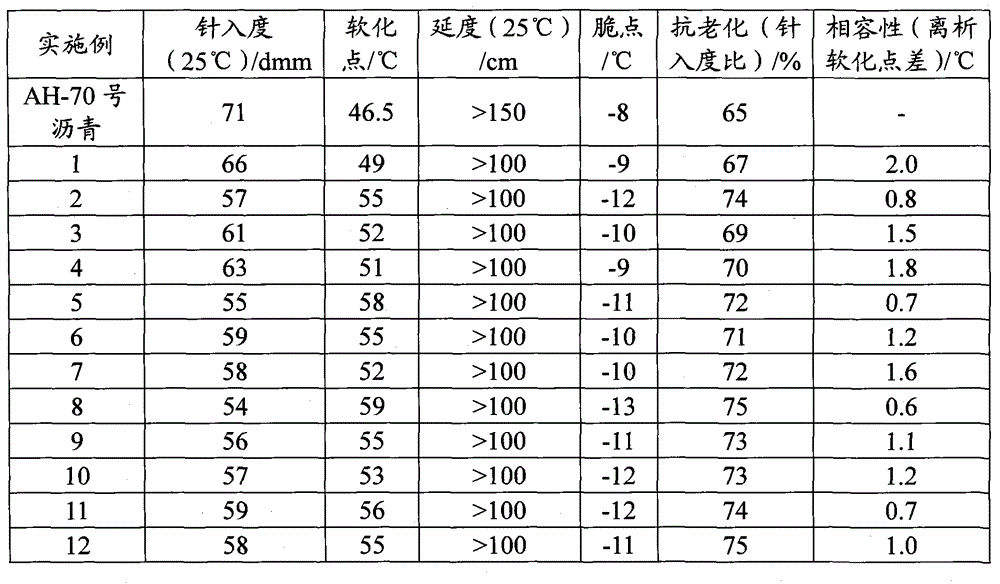

Examples

Embodiment 1

[0019] The method of recycling waste FCC catalyst, the specific method is as follows: use a vibrating sieve to screen the waste FCC catalyst, wherein, the particle size greater than 40 μm is used as fine aggregate or filler in the asphalt mixture; the particle size is less than 40 μm The waste agent is used to modify asphalt.

[0020] On the basis of the above scheme, the method for modifying asphalt with the spent FCC catalyst with a particle size of less than 40 μm is as follows:

[0021] (1) Place the spent FCC catalyst with a particle size of less than 40 μm in an oven at 120° C. for heating and drying, and then place it in a desiccator to cool to room temperature for use;

[0022] (2) Weigh 200 g of the dried spent FCC catalyst and place it in a three-necked flask, and place it in a water bath to control the temperature at 20°C, weigh 1 g of sodium methyl silicate, and stir the two together for 10 minutes;

[0023] (3) Weigh 500g of No. AH-70 asphalt and place it in the ...

Embodiment 2

[0025] The method for modifying asphalt by using the waste agent with a particle size less than 40 μm is as follows:

[0026] (1) heating and drying the spent FCC catalyst with a particle size of less than 40 μm in an oven at 120° C.;

[0027] (2) Weigh 200g of the dried waste FCC catalyst and place it in a three-necked flask, and place it in an oil bath to control the temperature at 100°C, weigh 10g of sodium methyl silicate, and stir the two together for 30 minutes ;

[0028] (3) Weigh 500g of AH-70 asphalt and put it in the sample barrel, then place it in a heating mantle and raise the temperature to 150°C, slowly add 100g of spent catalyst treated with sodium methyl silicate into the asphalt, and perform shear mixing , with a rotational speed of 10,000 rpm and a shear of 60 min to prepare spent catalyst-modified asphalt, and test its penetration, softening point, ductility, brittle point, anti-aging and compatibility indicators.

Embodiment 3

[0030] The method for modifying asphalt by using the waste agent with a particle size less than 40 μm is as follows:

[0031] (1) heating and drying the spent FCC catalyst with a particle size of less than 40 μm in an oven at 120° C.;

[0032] (2) Weigh 200 g of the dried waste FCC catalyst and place it in a three-necked flask, and place it in a water bath to control the temperature at 70°C, weigh 5 g of sodium methyl silicate, and stir the two together for 20 minutes;

[0033] (3) Weigh 500g of No. AH-70 asphalt and place it in the sample barrel, then put it in a heating mantle and raise the temperature to 135°C, slowly add 75g of the spent catalyst treated with sodium methyl silicate into the asphalt, and perform shear mixing , rotating at 7000 rpm, shearing for 30 minutes, prepared spent catalyst modified asphalt, and tested its penetration, softening point, ductility, brittle point, anti-aging and compatibility indicators.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com