A multi-dimensional electrode treatment process for shale gas flowback fluid

A multi-dimensional electrode, processing technology technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

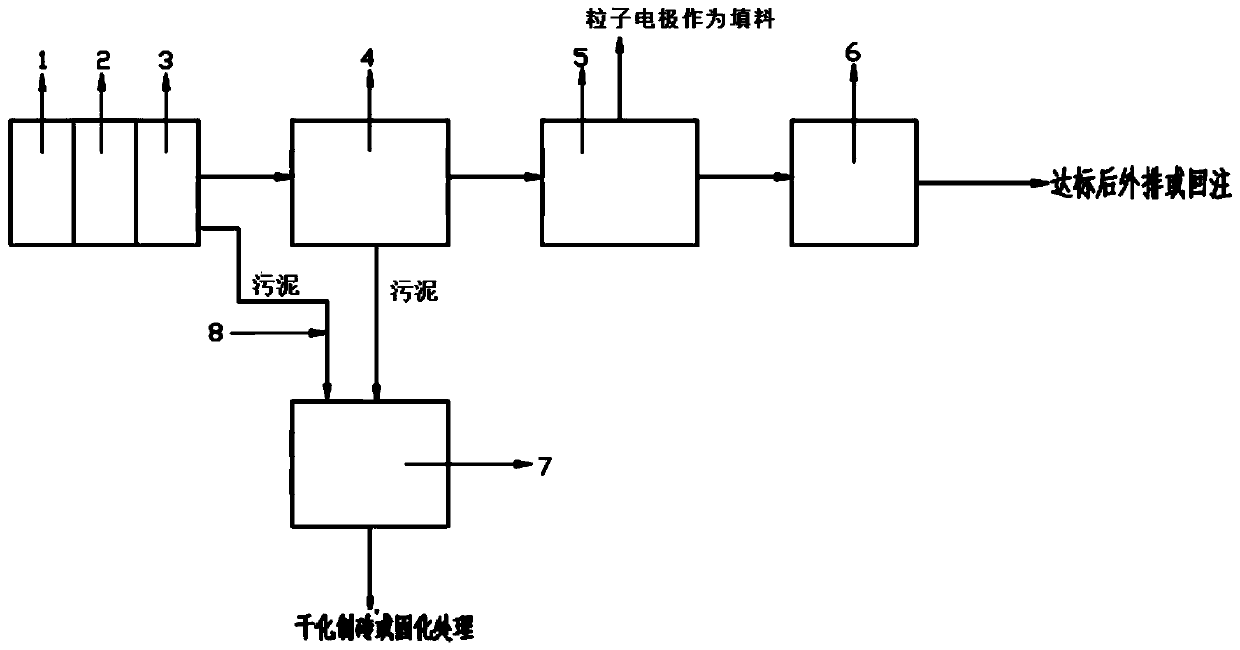

[0042] Shale gas flowback liquid multi-dimensional electrode treatment process, the steps are as follows:

[0043] (1) Sand settling: remove large particles and cuttings in shale gas flowback liquid; remove larger suspended particles and cuttings in shale gas flowback liquid through natural settlement.

[0044] (2) Chemical coagulation: Add coagulant agent to the flowback liquid after sand settling in step (1), adjust the pH to 6 during the coagulation process, and precipitate; specifically, add a certain amount of polyaluminum chloride (PAC ), after stirring for a period of time, a certain concentration of polyacrylamide (PAM) is added to make the colloidal suspended matter flocculate with each other to form large particles and then precipitate and remove;

[0045] The concentration of polyaluminum chloride is 30%-40%, and the concentration of PAM is 0.1%-0.5%. The concentration and dosage are determined according to the change of water quality. The molecular weight of polya...

Embodiment 2

[0054] The multi-dimensional electrode treatment process for shale gas flowback liquid is characterized in that it includes the following steps:

[0055] (1) Sand settling: remove large particles and cuttings in shale gas flowback liquid; remove larger suspended particles and cuttings in shale gas flowback liquid through natural settlement.

[0056] (2) Chemical coagulation: add coagulation agent to the flowback liquid after grit settling in step (1), adjust the pH to 8 during the coagulation process, and precipitate; specifically, first add a certain amount of polyaluminum chloride (PAC) , after stirring for a period of time, add a certain concentration of polyacrylamide (PAM) to make the colloidal suspended matter flocculate with each other to form large particles, and then precipitate and remove;

[0057] The concentration of polyaluminum chloride is 40%, and the concentration of PAM is generally 0.2%. The concentration and dosage are determined according to the change of w...

Embodiment 3

[0071] The shale gas flowback liquid treatment process based on multi-dimensional electrode technology includes the following steps:

[0072] (1) First, the shale gas flowback fluid passes through the grit chamber to remove large particles;

[0073] (2) Then enter the coagulation tank for coagulation treatment, first add polyaluminum chloride (PAC), the concentration is controlled between 35%, stir for 30 seconds, then add polyacrylamide (PAM), its molecular weight is 8 million, The concentration is controlled at 0.3%, and the stirring time is 30 seconds. After a large number of flocs appear in the water, it enters the sedimentation tank for static precipitation, and the resulting sediment enters the sludge thickening tank for concentration and collection.

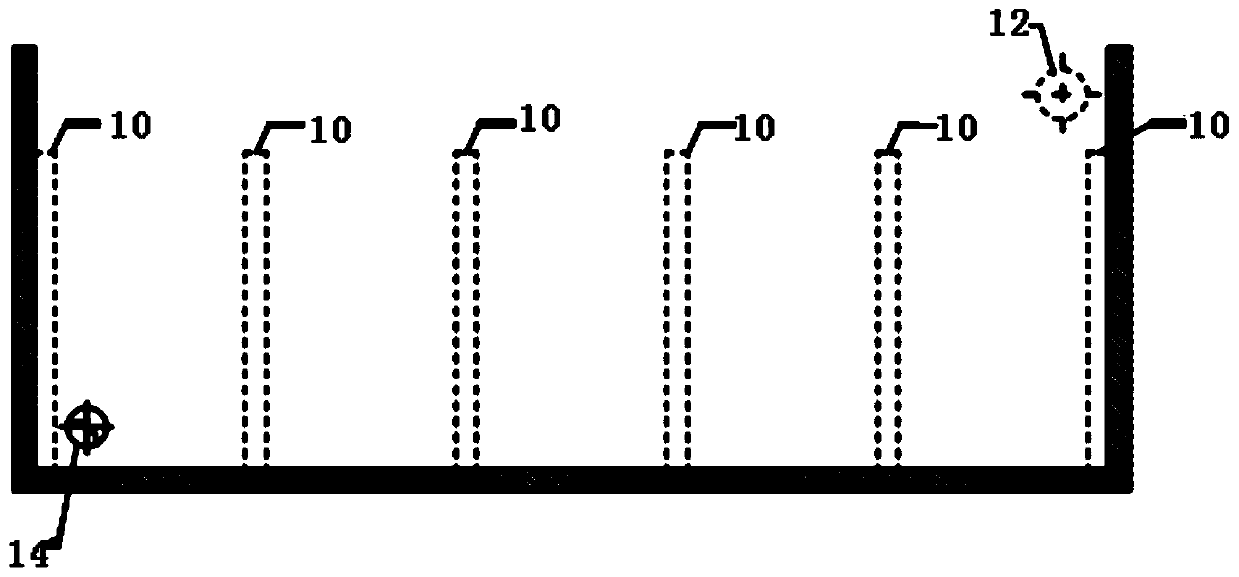

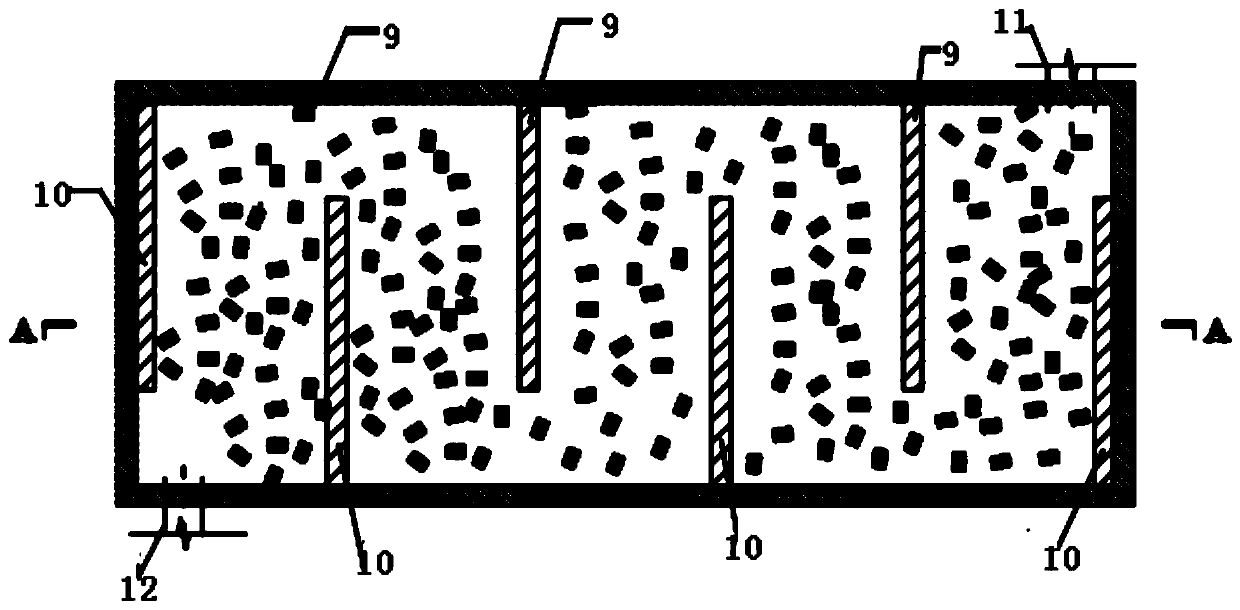

[0074] (3) The treated shale gas flowback liquid enters the electrocoagulation device, which uses iron sheets as electrode plates to remove heavy metal ions in the wastewater through redox and flocculation precipitation. P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com