Continuous production method of graphite coated material

A production method and graphite coating technology are applied in the field of continuous production of graphite coating materials, which can solve the problems of uneven distribution of asphalt family components, low residual carbon content, complicated processes, etc., so as to achieve product industrialization, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

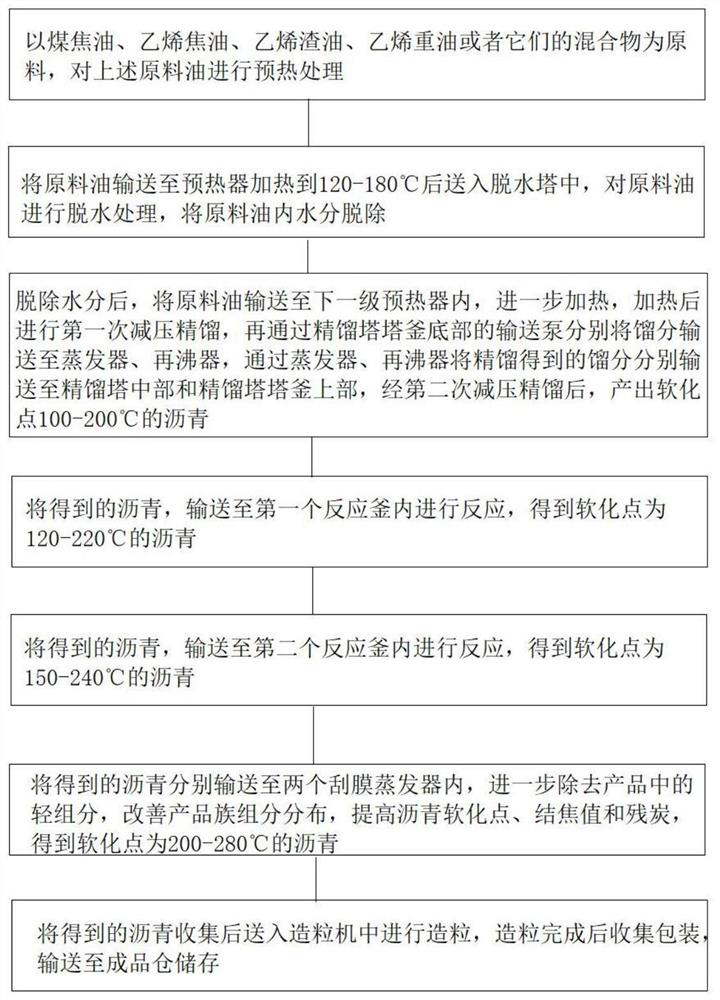

Method used

Image

Examples

Embodiment 1

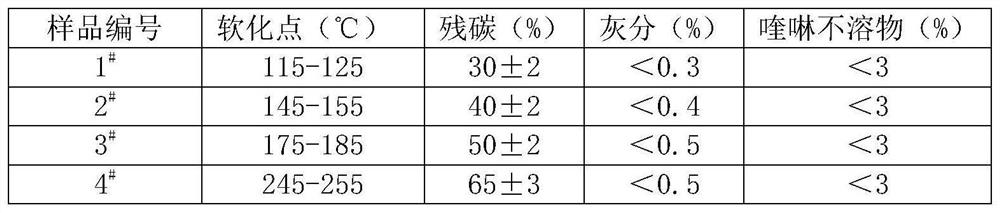

[0037] Number the asphalt samples with four different softening points, among them:

[0038] 1 # Bitumen with a softening point of 100-200°C;

[0039] 2 # Bitumen with a softening point of 120-220°C;

[0040] 3 # Bitumen with a softening point of 150-240°C;

[0041] 4 # Bitumen with a softening point of 200-280°C;

[0042] The four samples of asphalt were inspected separately, as attached figure 2 As shown, the results show that the asphalt with a softening point of 200-280°C has higher carbon residue content, higher ash content, and lower content of quinoline insolubles in the product than the other three softening point samples, and the application effect is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com