Coal liquefaction residue modified asphalt and preparation method and application thereof

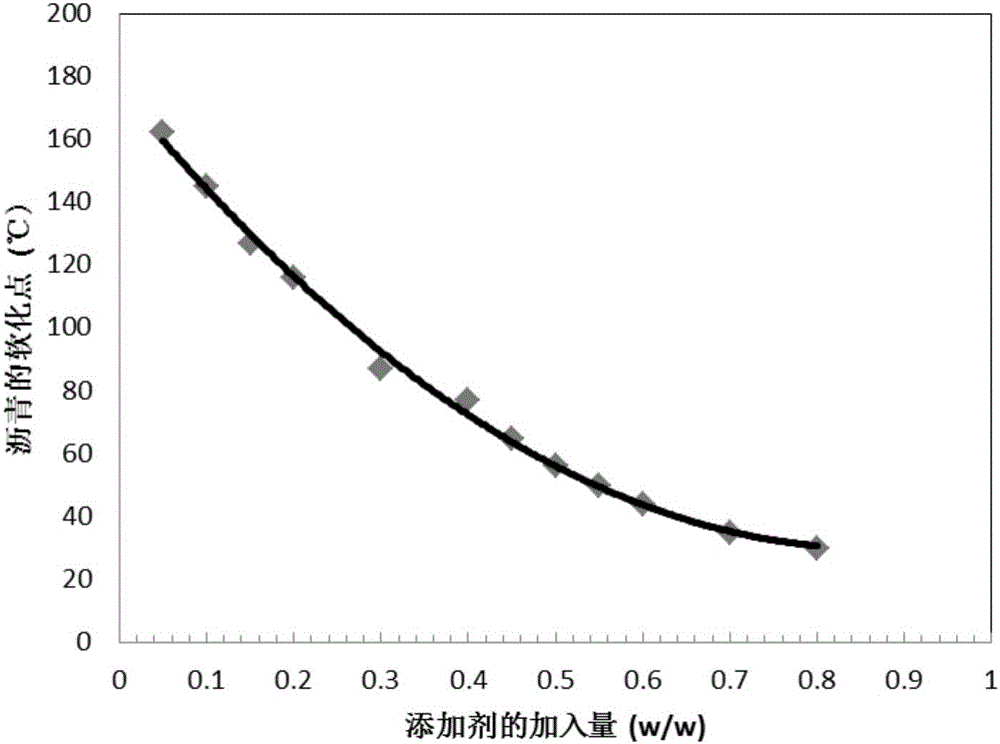

A technology of coal liquefaction residue and modified asphalt, which is applied in the processing of tar pitch/petroleum pitch/natural pitch, processing tar pitch/petroleum pitch/natural pitch through mixed fractions, and the petroleum industry, which can solve the problems of increasing product production costs and Operating costs, poor control of the softening point of modified asphalt, increased process complexity and other issues, to achieve the effect of high controllability of product properties, uniform phase, and small reproducibility error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This example illustrates the method of the present invention for preparing coal liquefaction residue modified asphalt.

[0047] (1) 55% by weight of Additive A and 45% by weight of Additive B are prepared and mixed uniformly to obtain a composite additive, and the measured aromatic content is 62% by weight.

[0048] (2) heating 45 parts by weight of the composite additive to 190° C. under stirring; then slowly adding 55 parts by weight of coal liquefaction residue A;

[0049] (3) After adding the coal liquefaction residue A, continue stirring at 190° C. for 40 minutes to obtain the coal liquefaction residue modified asphalt.

[0050] The obtained coal liquefaction residue modified bitumen was observed by photography. Such as Figure 1a As shown, it can be seen that the coal liquefaction residue modified asphalt has a uniform phase and no oil phase segregation. The softening point was measured to be 64.5°C.

[0051] The above experiment was repeated twice, and the obt...

Embodiment 2

[0054] This example illustrates the method of the present invention for preparing coal liquefaction residue modified asphalt.

[0055] (1) 45 parts by weight of additive A (75.2% by weight of aromatic content) was heated to 250° C. under stirring; then 55 parts by weight of coal liquefaction residue B were slowly added;

[0056] (2) After adding the coal liquefaction residue, continue stirring at 250° C. for 20 minutes to obtain the coal liquefaction residue modified asphalt.

[0057] The obtained coal liquefaction residue modified bitumen was observed by photography. Such as image 3 As shown, it can be seen that the coal liquefaction residue modified asphalt has a uniform phase and no oil phase segregation. The softening point was determined to be 56°C.

[0058] Same as Example 1, the above experiment was repeated twice, and the reproducibility error of the softening point of the obtained coal liquefaction residue modified asphalt was less than 3°C, indicating that the re...

Embodiment 3

[0061] According to the method of Example 1, the difference is that in step (2), "heat 3 parts by weight of the composite additive to 190 °C under stirring; then slowly add 97 parts by weight of coal liquefaction residue A", replace "the 45 parts by weight of composite additives are heated to 190°C under stirring; then 55 parts by weight of coal liquefaction residue A" are slowly added.

[0062] Obtained coal liquefaction residue modified asphalt, and carried out photographic observation, it can be seen that the phase is uniform, no oil phase is separated out, and the softening point of the obtained homogeneous modified asphalt product is 170°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com