Pretreatment process of raw materials for preparing coal-based needle coke

A needle coke and pretreatment technology, applied in the processing of tar pitch/petroleum pitch/natural pitch, coke oven, petroleum industry, etc., can solve the problem of complex composition of coal tar pitch, unsatisfactory, increasing production cost of needle coke, etc. problems, to achieve the effect of broadening the range of raw material selection, reducing production costs, and reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

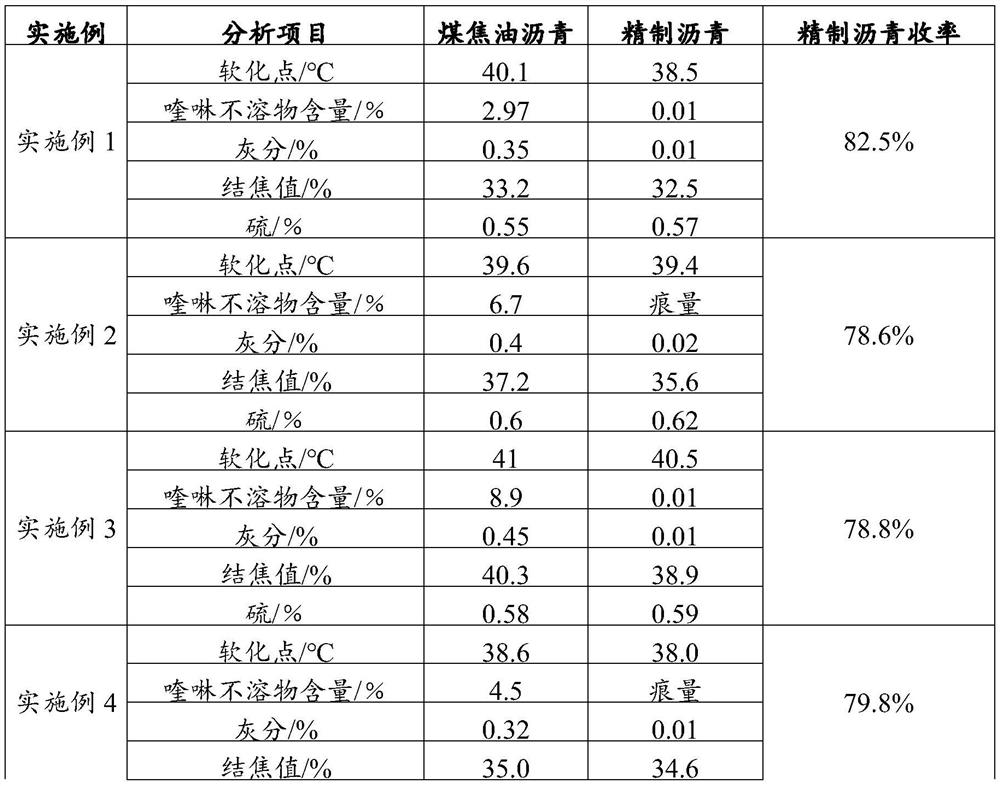

Examples

Embodiment 1

[0024] The pretreatment process for preparing raw materials of coal-based needle coke of the present embodiment includes the following steps:

[0025] (1) Raw material mixing: mix coal tar pitch (sulfur 0.6%, quinoline insolubles 6.7%) and solvent at 90° C. and normal pressure according to a mass ratio of 0.5:1 to obtain a mixed solution;

[0026] (2) Primary sedimentation: Before injecting the material, according to the mass ratio of solvent: coal tar pitch = 0.2:1, inject solvent into the bottom of the primary sedimentation tank, and then add the mixed solution obtained in step (1) into the primary sedimentation tank for a Settling treatment, the temperature of the first settling is 90℃, and the time of the first settling is 4h. After the first settling is completed, the heavy components are extracted from the bottom of the primary settling tank, and the light components are extracted from the top of the primary settling tank;

[0027] (3) Secondary sedimentation: Before inj...

Embodiment 2

[0032] The pretreatment process for preparing raw materials of coal-based needle coke of the present embodiment includes the following steps:

[0033] (1) Raw material mixing: mix coal tar pitch (sulfur 0.6%, quinoline insolubles 6.7%) and solvent at 110° C. and normal pressure according to a mass ratio of 1:1 to obtain a mixed solution;

[0034] (2) Primary sedimentation: Before injecting the material, according to the mass ratio of solvent: coal tar pitch = 0.3:1, inject solvent into the bottom of the primary sedimentation tank, and then add the mixed solution obtained in step (1) into the primary sedimentation tank for a Settling treatment, the temperature of one settling is 110℃, the time of one settling is 3h, after the first settling is completed, the heavy components are extracted from the bottom of the primary settling tank, and the light components are extracted from the top of the primary settling tank;

[0035](3) Secondary sedimentation: Before injecting the materi...

Embodiment 3

[0040] The pretreatment process for preparing raw materials of coal-based needle coke of the present embodiment includes the following steps:

[0041] (1) Mixing of raw materials: mix coal tar pitch (sulfur 0.58%, quinoline insolubles 8.9%) and solvent at 130° C. and normal pressure according to a mass ratio of 1.5:1 to obtain a mixed solution;

[0042] (2) Primary sedimentation: Before injecting the material, according to the mass ratio of solvent: coal tar pitch = 0.4:1, inject the solvent into the bottom of the primary sedimentation tank, and then add the mixed solution obtained in step (1) into the primary sedimentation tank for a Settling treatment, the temperature of the first settling is 130℃, the time of the first settling is 2h, after the first settling is completed, the heavy components are extracted from the bottom of the primary settling tank, and the light components are extracted from the top of the primary settling tank;

[0043] (3) Secondary sedimentation: Bef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com