Blending asphalt and preparation method thereof

A technology for blending and asphalt, which is applied in the field of blending asphalt and its preparation, and can solve the problems of inability to meet the requirements of petroleum asphalt indicators and poor indicators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention also provides a preparation method of the blended asphalt, comprising: mixing deoiled asphalt, vacuum residue and petroleum asphalt, heating and stirring to obtain heavy traffic road petroleum asphalt.

[0029] Wherein, the heating temperature is preferably 100°C to 200°C, more preferably 130°C to 160°C; the heating and stirring time is preferably 20 to 200min, more preferably 30 to 120min; the heating and stirring is preferably at a high speed Stirring; the stirring speed is preferably 1000-2000r / min, more preferably 1000r / min.

[0030] The preparation method provided by the invention is simple, and the prepared blended asphalt meets the index requirement of JTG F40-2004, the road petroleum asphalt technical requirement of the Ministry of Communications.

Embodiment 1

[0034] Use deoiled asphalt (penetration at 25°C 20-40dmm, softening point 50°C-70°C), vacuum residue (penetration at 25°C 200-300dmm, softening point 20°C-40°C, flash point 260°C- 350°C) and base petroleum asphalt (25°C penetration 60-80dmm, softening point > 46°C, flash point 260°C-280°C, 10°C ductility > 150cm) at 150 cm according to the mass ratio of 2.5:2.5:5 After stirring at ℃ for 60 minutes, a well-mixed blended pitch was obtained, the properties of which are shown in Table 1.

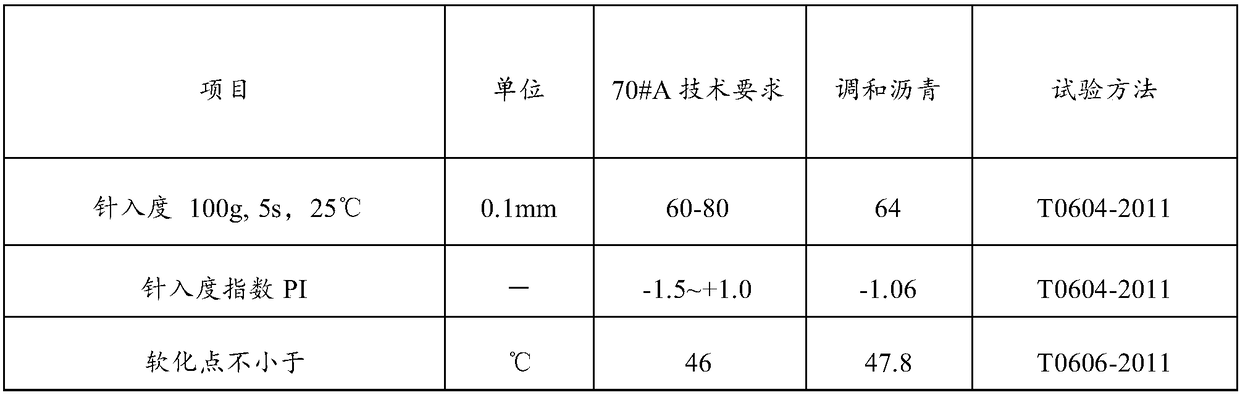

[0035] The properties of the blended asphalt that table 1 embodiment 1 obtains

[0036]

[0037]

[0038] It can be seen from Table 1 that all indicators of blended asphalt after blending deoiled asphalt, vacuum residue and petroleum asphalt meet the technical requirements of 70#A grade asphalt in JTG F40-2004 of the Ministry of Communications.

Embodiment 2

[0040] Use deoiled asphalt (penetration at 25°C 0-20dmm, softening point 65°C-80°C), vacuum residue (penetration at 25°C 200-300dmm, softening point 20°C-40°C, flash point 260-350 ℃) and base petroleum asphalt (penetration at 25℃: 60-80dmm, softening point>46℃, flash point: 260℃-280℃, ductility>150cm at 10℃) according to the ratio of 2.4:4.6:3 at 150℃ for 60min Finally, a well-mixed blended asphalt is obtained, and its properties are shown in Table 2.

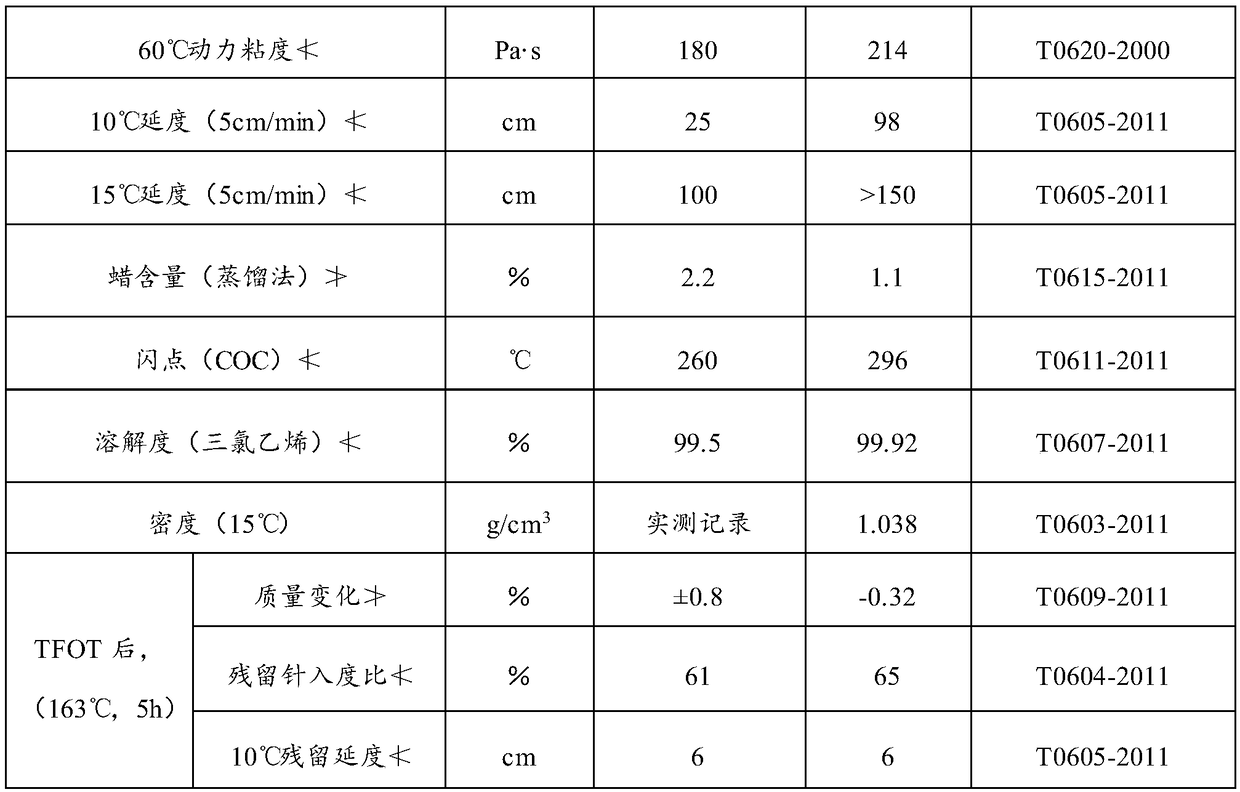

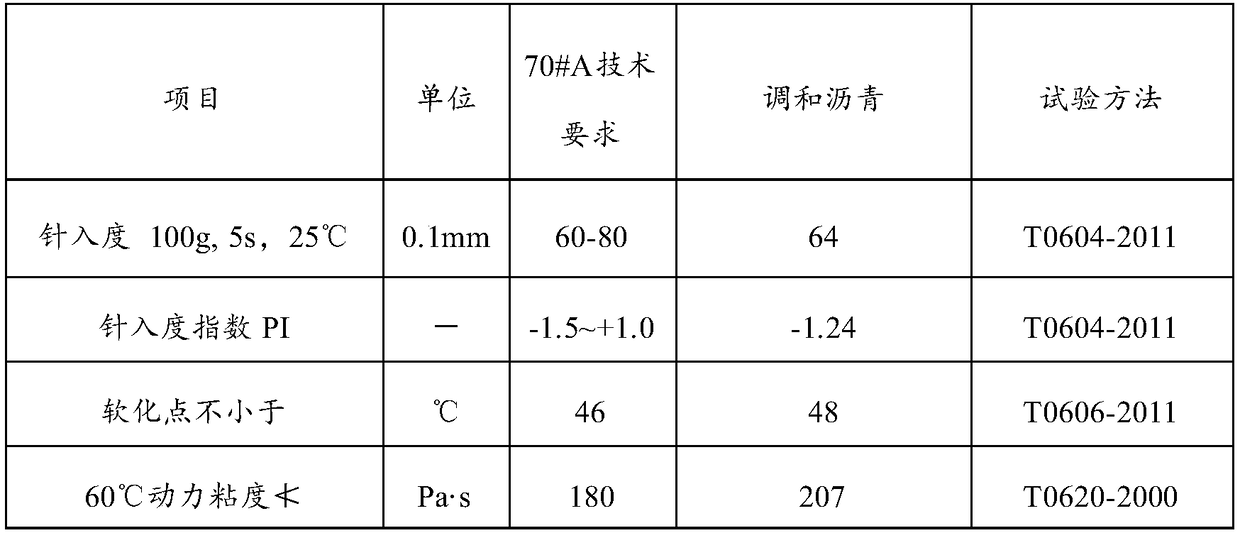

[0041] The properties of the blended asphalt that table 2 embodiment 2 obtains

[0042]

[0043]

[0044] It can be seen from Table 2 that all indicators of blended asphalt after blending deoiled asphalt, vacuum residue and petroleum asphalt meet the technical requirements of 70#A grade asphalt in JTG F40-2004 of the Ministry of Communications.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com