Drying method for cultured spirulina mud

A drying method and technology of spirulina, applied in the direction of drying solid materials, drying gas arrangement, non-progressive dryers, etc., can solve the problems of large differences in efficiency and cost, damage to spirulina, and different drying temperatures, and achieve easy management and maintenance. , to achieve the effect of mechanization and good material quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the examples.

[0025] Those skilled in the art will understand that the following examples are only used to illustrate the present invention and should not be considered as limiting the scope of the present invention. If no specific technique or condition is indicated in the examples, it shall be carried out according to the technique or condition described in the literature in this field or according to the product specification. The materials or equipment used are not indicated by the manufacturer, and they are all conventional products that can be obtained through purchase.

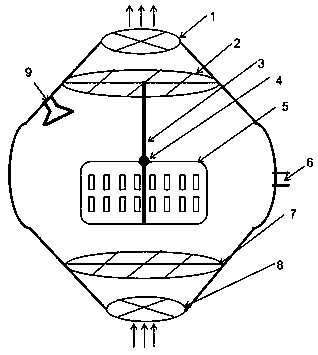

[0026] A drying method for cultivating spirulina algae mud, comprising an exhaust fan 1, a stainless steel gauze 2, a rotating shaft 3, a temperature control sensor 4, a heat transfer oil radiator 5, a drying outlet 6, a stainless steel gauze 7, an inlet fan 8 and an algae mud inlet 9 constitute a round altar t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com