Metal melting furnace

A melting furnace and melting technology, applied in furnaces, furnace components, metallurgical equipment, etc., can solve problems such as difficult to completely remove impurities, reduced retention of molten liquid, and difficult operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings.

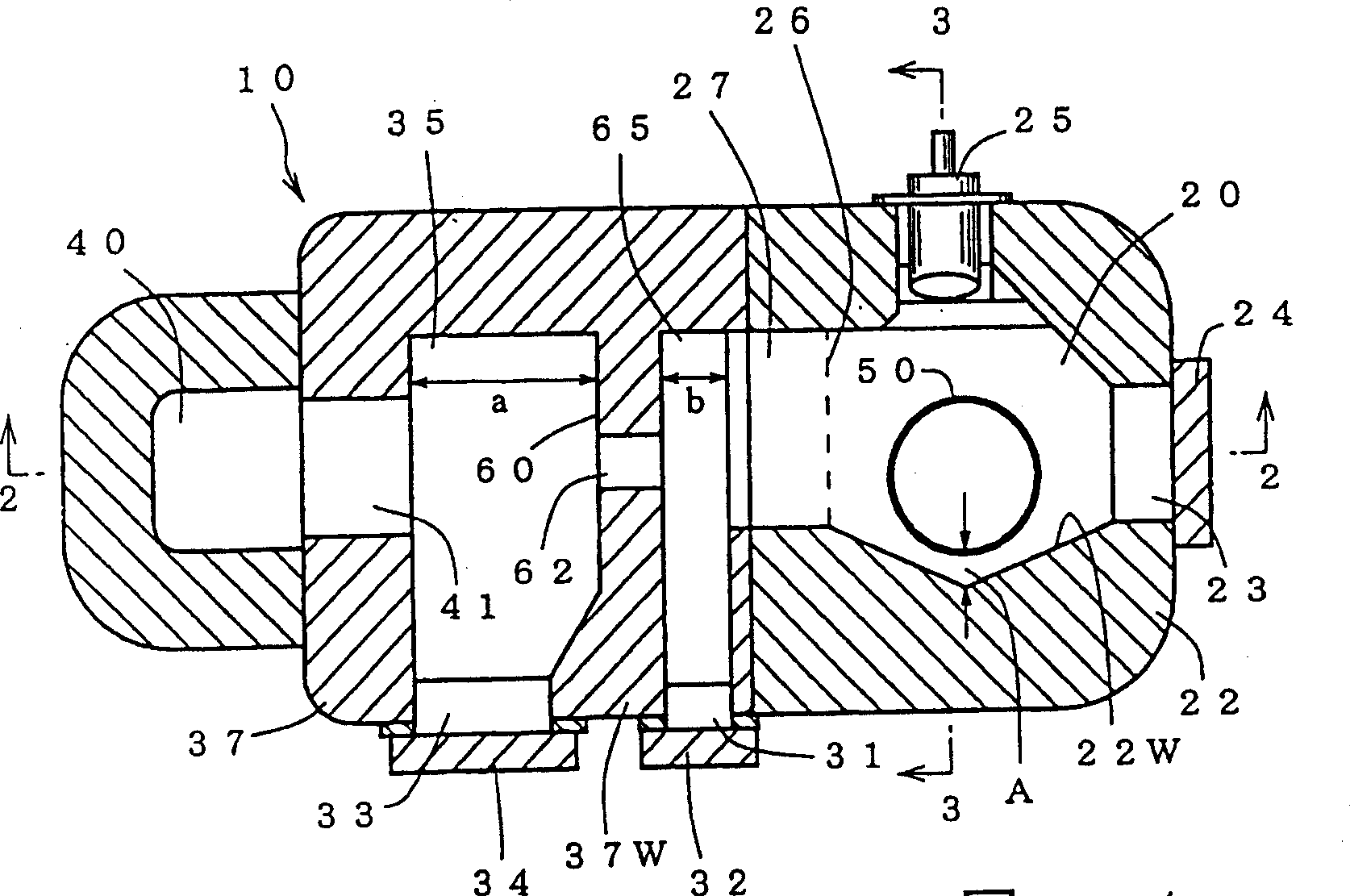

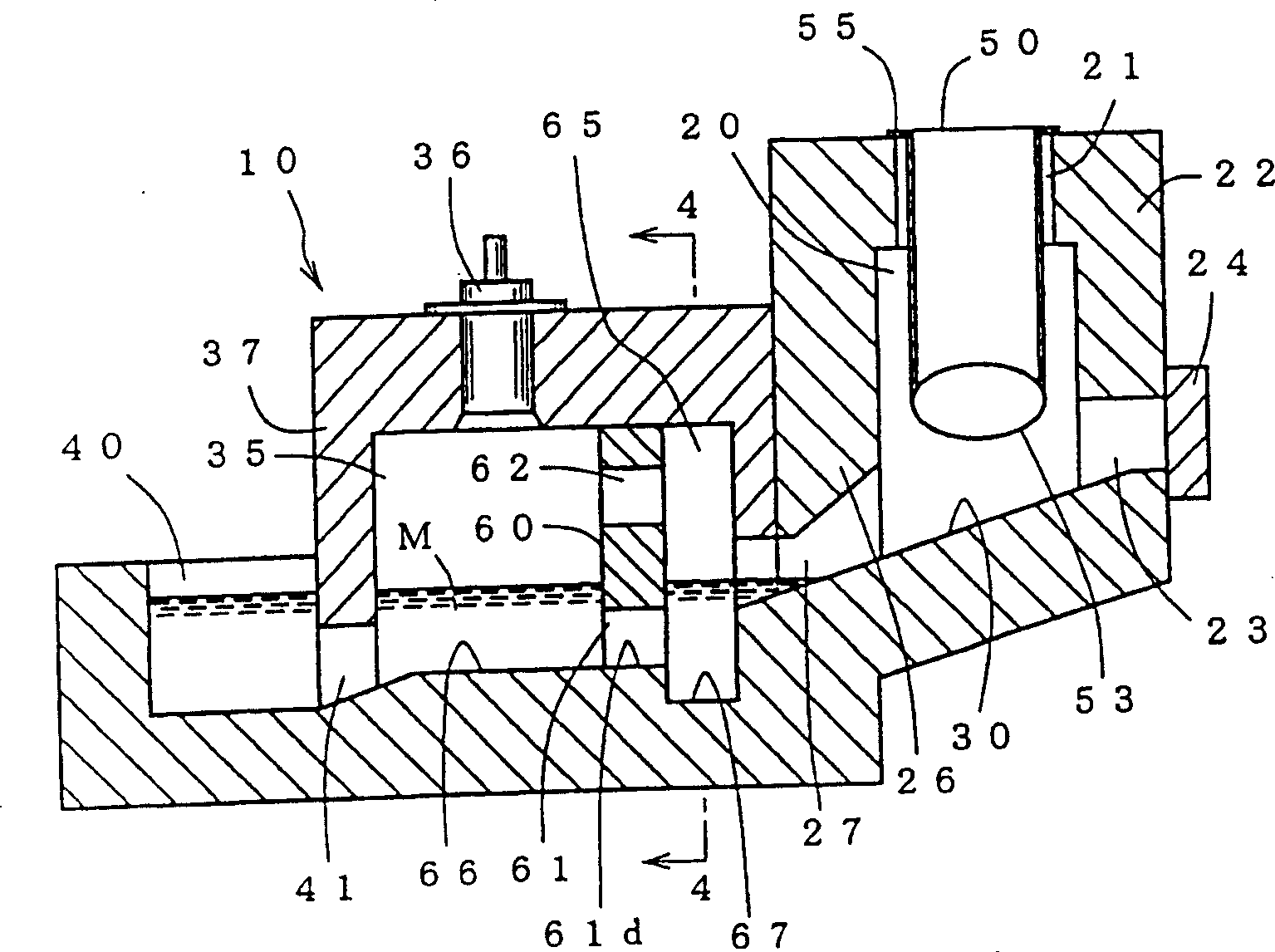

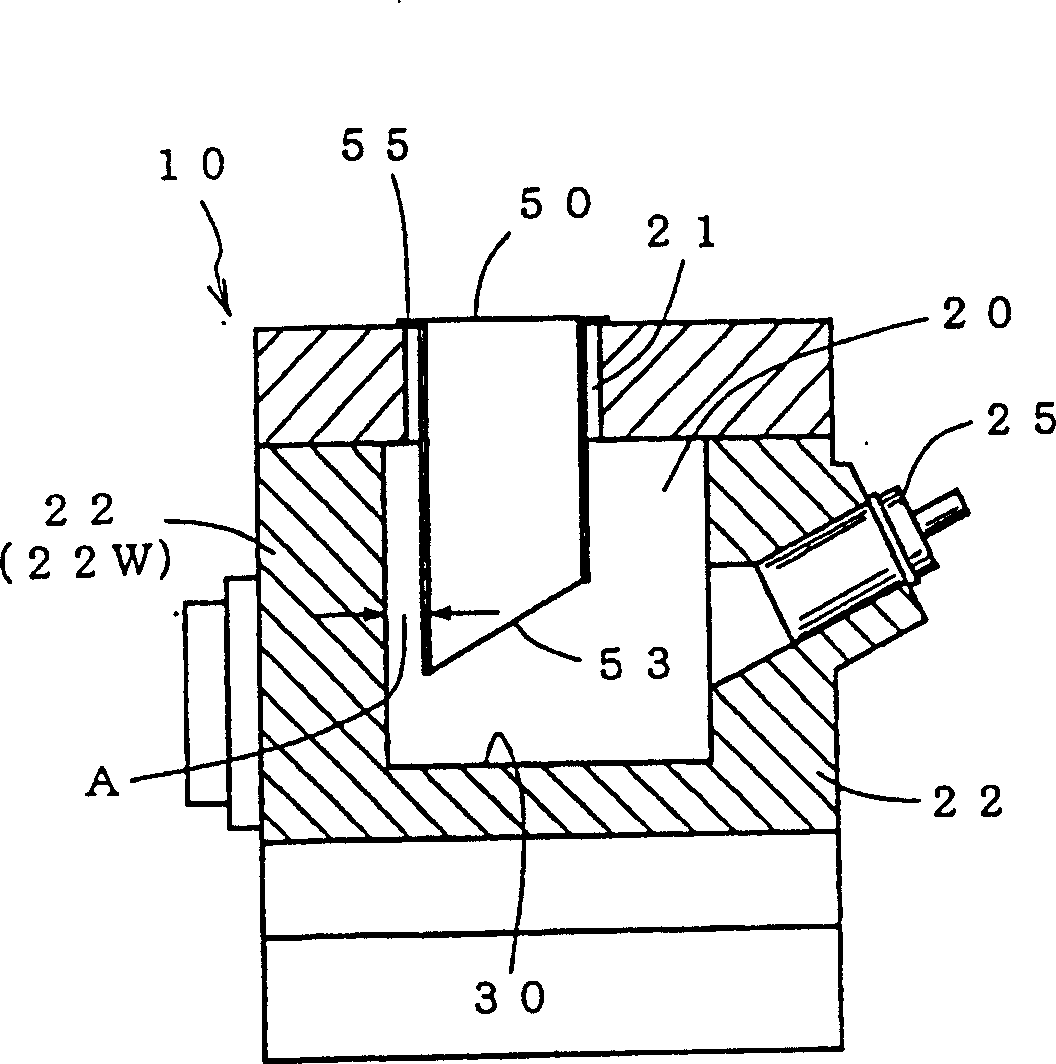

[0025] figure 1 is an overall schematic cross-sectional view of a metal melting furnace showing an embodiment of the present invention, figure 2 is along figure 1 The cross-sectional view of the 2-2 line cut, image 3 is along figure 1 The enlarged cross-sectional view of the 3-3 line cut, Figure 4 is along figure 2 Sectional drawing of the 4-4 line cut.

[0026] The metal melting furnace 10 in the embodiment is a so-called hand melting furnace that melts and holds molten aluminum for aluminum casting, such as Figure 1 to Figure 4 As shown, after the molten material is inserted into the preheating flue 20 formed as a material inlet (and exhaust port) 21 at the upper part and has an inclined furnace bottom 30 at the lower part, the melting burner arranged toward the aforementioned preheating flue 20 is used to 25. The molten material is heated and melted, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com