Combined type multi-injector burner

A burner, multi-nozzle technology, which is applied in the burner, the combination of multiple burners, the burner burning powder fuel, etc., can solve the problems of increased furnace length, no ignition device, unsuitability, etc. The furnace temperature field is uniform, the flow field is uniform, and the resistance is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

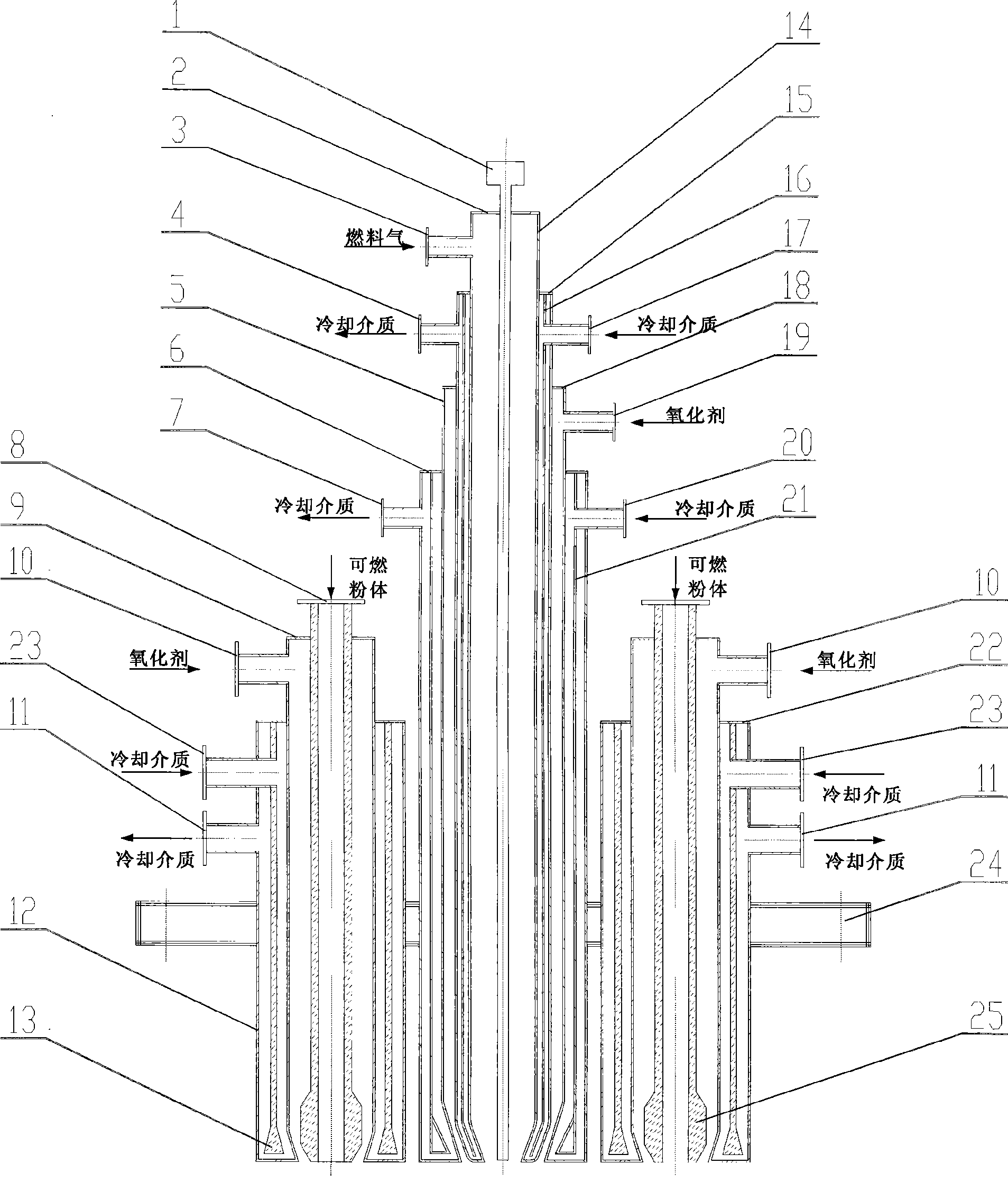

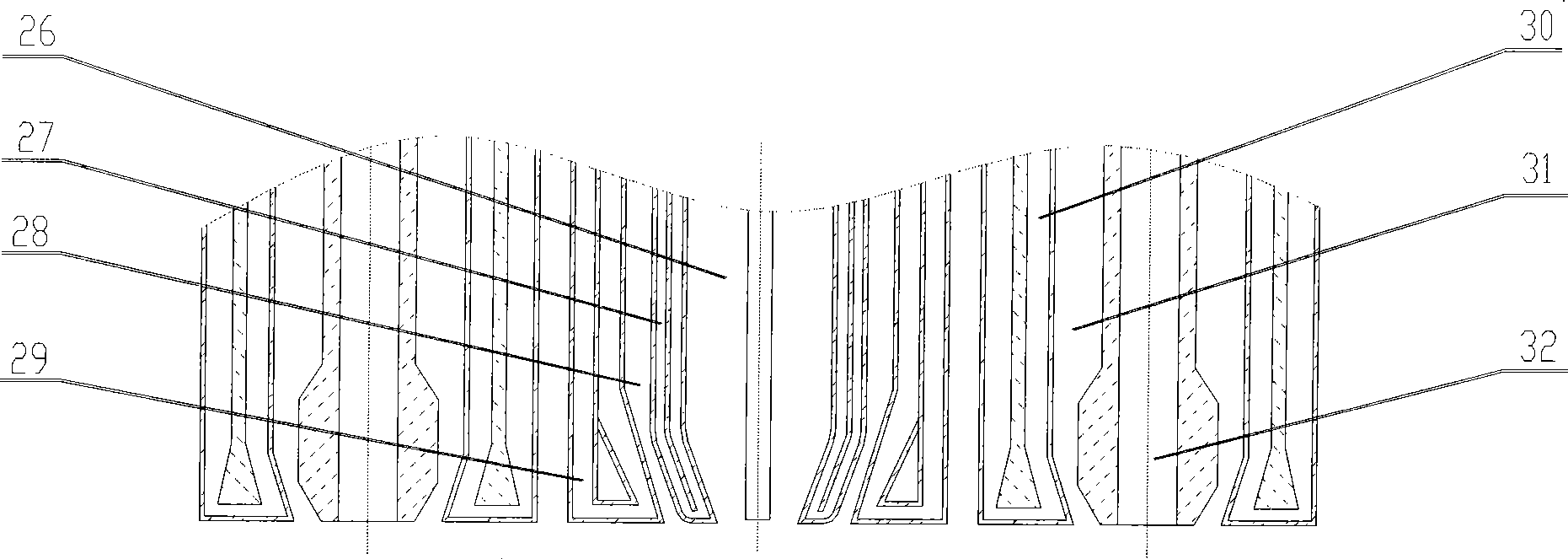

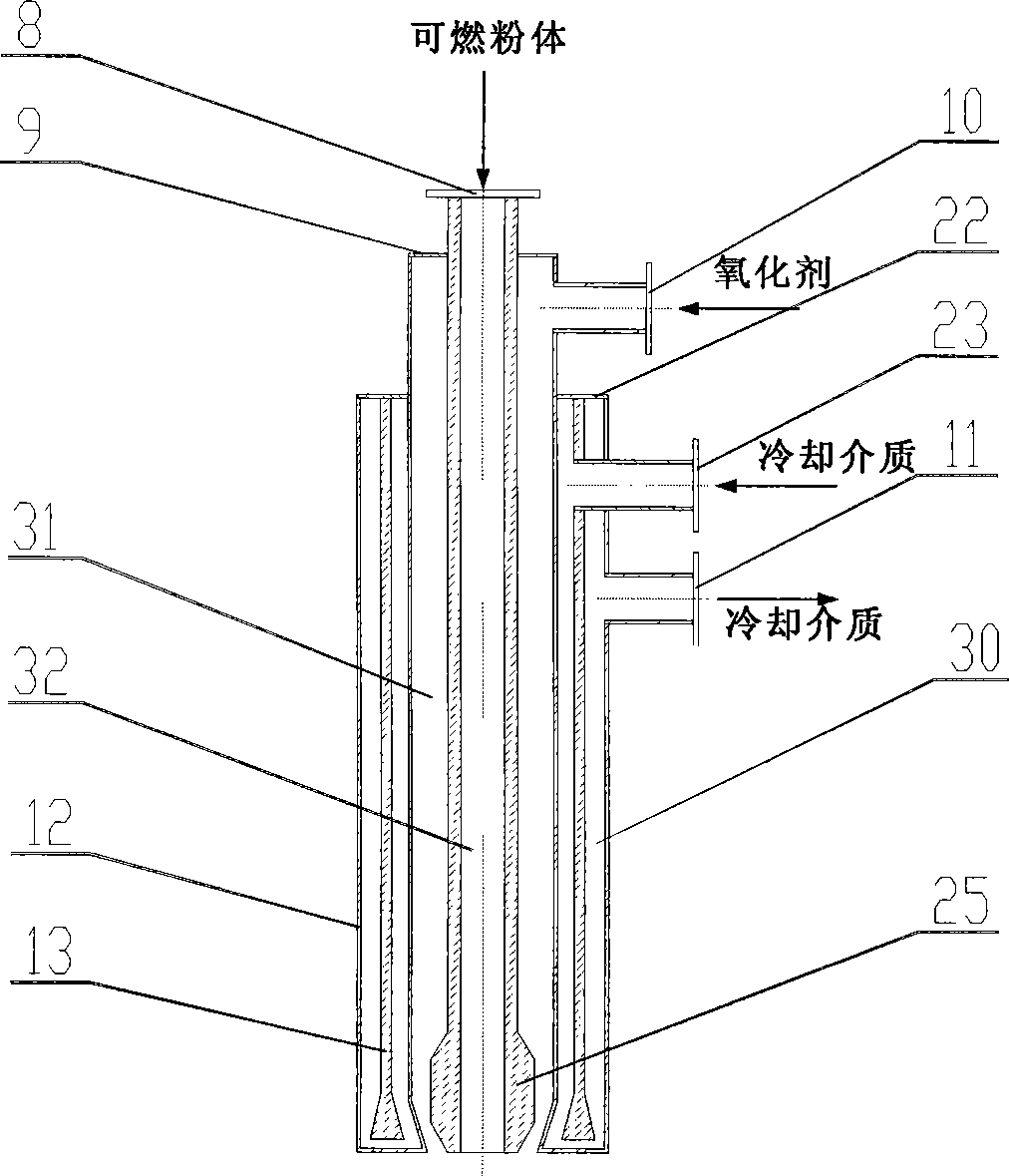

[0022] The most preferred structure of the burner of the present invention will be described in detail below with reference to the accompanying drawings of the present invention.

[0023] see figure 1 , the burner of the present invention includes an ignition burner arranged in the middle and a plurality of process burners arranged outside the ignition burner. The process burners are evenly arranged around the ignition burners along the circumferential direction, and are fixed together with the ignition burners through the installation flange 24, which is sealed and connected with the furnace body (not shown). The number of process burners is preferably 2-10, and the working load of the burners can be adjusted by increasing or decreasing the number of working process burners. By using the mounting flange 24 to fix the process burner and the ignition burner, during maintenance, the parts that need to be repaired can be disassembled and repaired separately without affecting oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com