Method for measuring blast furnace lining corroding thickness

A blast furnace lining and hearth technology, applied in measuring devices, measuring heat, thermometers, etc., can solve problems such as the limitation of the hearth erosion thickness, the multi-head galvanic couple embedded in the hearth can not cover the circumference, etc., to prolong the life of the blast furnace Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

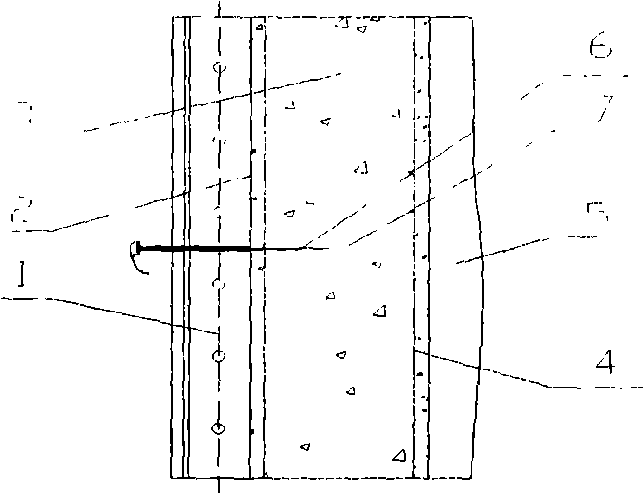

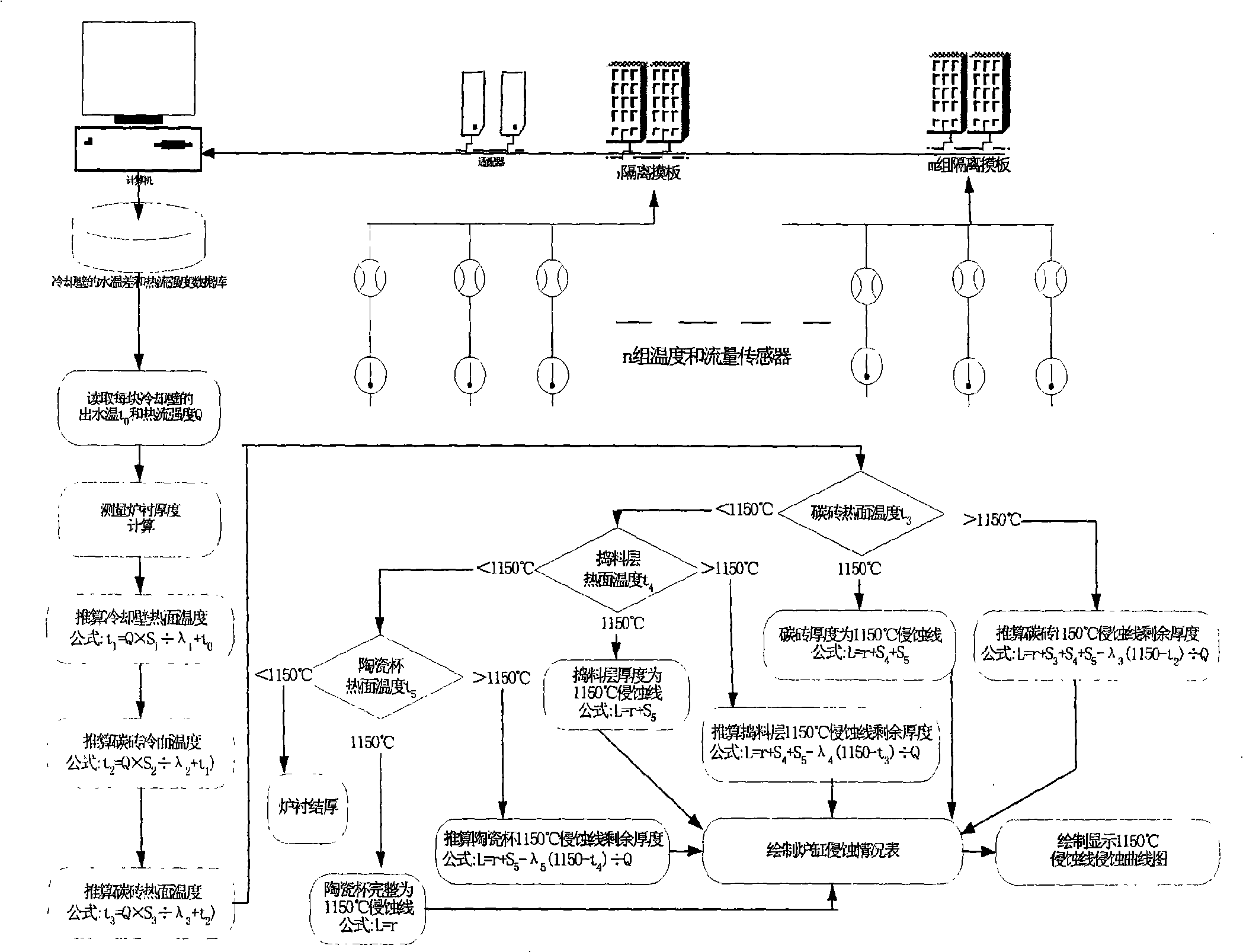

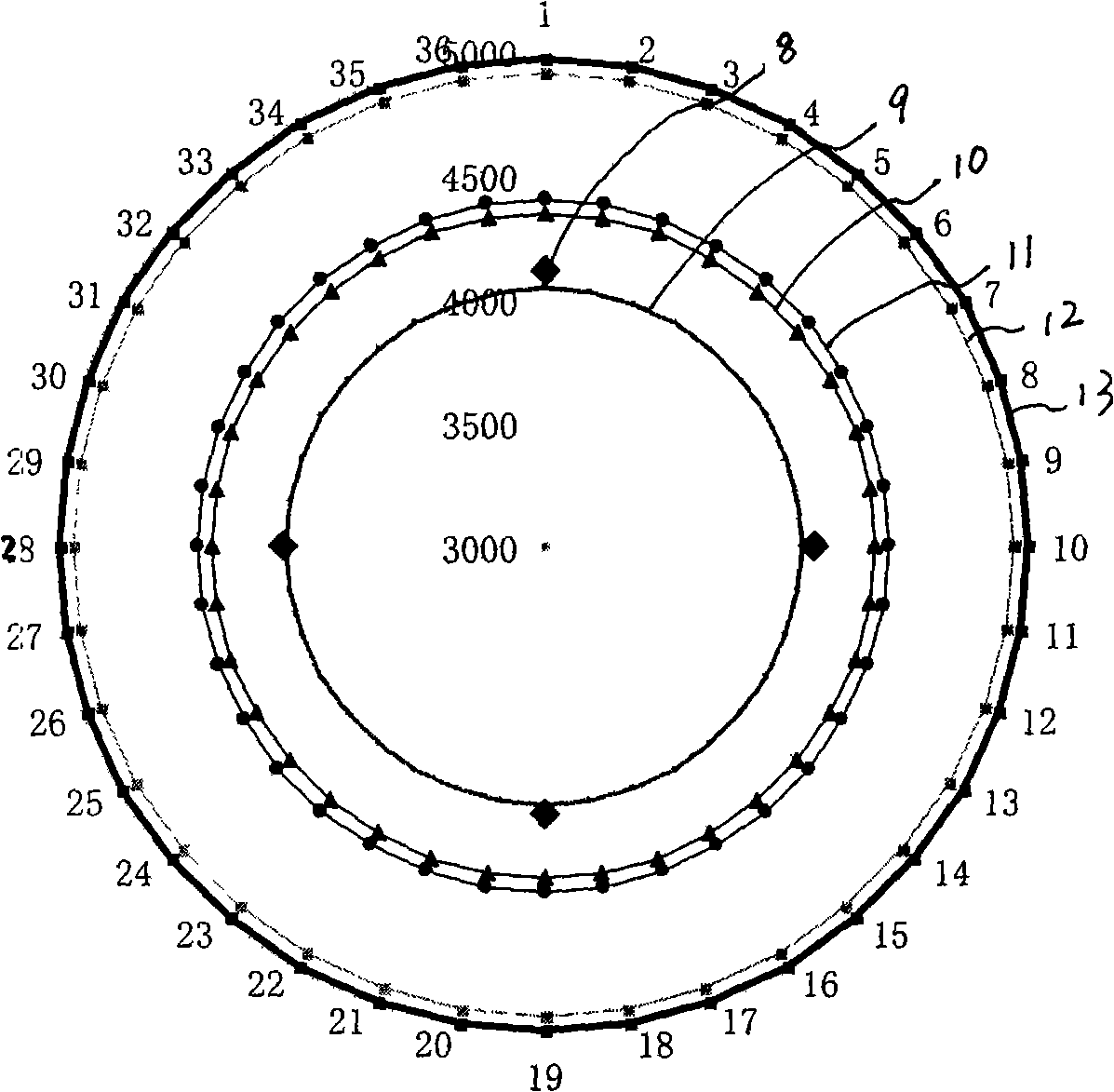

[0034] refer to figure 1 , the end surface structure of the furnace lining is composed of cast iron stave 1, filler 2 between the stave and carbon brick, hearth carbon brick 3, filler 4 between the ceramic cup and carbon brick, and the remaining ceramic cup wall 5. Even, the radius r can be measured 1 Position galvanic temperature T 1 6 and radius r 2 Position galvanic temperature T 2 7. refer to figure 2 , first use the on-line automatic detection device for the heat flux intensity of the hearth stave to detect the heat flux intensity Q of each stave and the outlet water temperature t of the stave 0 , to calculate the interface temperature of the relative position of refractory materials of different materials: 1. cast iron stave, 2. filler between stave and carbon brick, 3. hearth carbon brick, 4. filler between ceramic cup and carbon brick, 5. The interface temperature of the ceramic cup wall, the thermal conductivity of refractory materials of different materials, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com