Multichambered stellmaking apparatus and method of steelmaking using this apparatus

A technology of molten steel and smelting chamber, applied in the field of iron smelting, can solve the problems of prolonging melting time, consumption, excessive dolomite and magnesium carbonate, etc., and achieve the effect of reducing consumption and ensuring working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

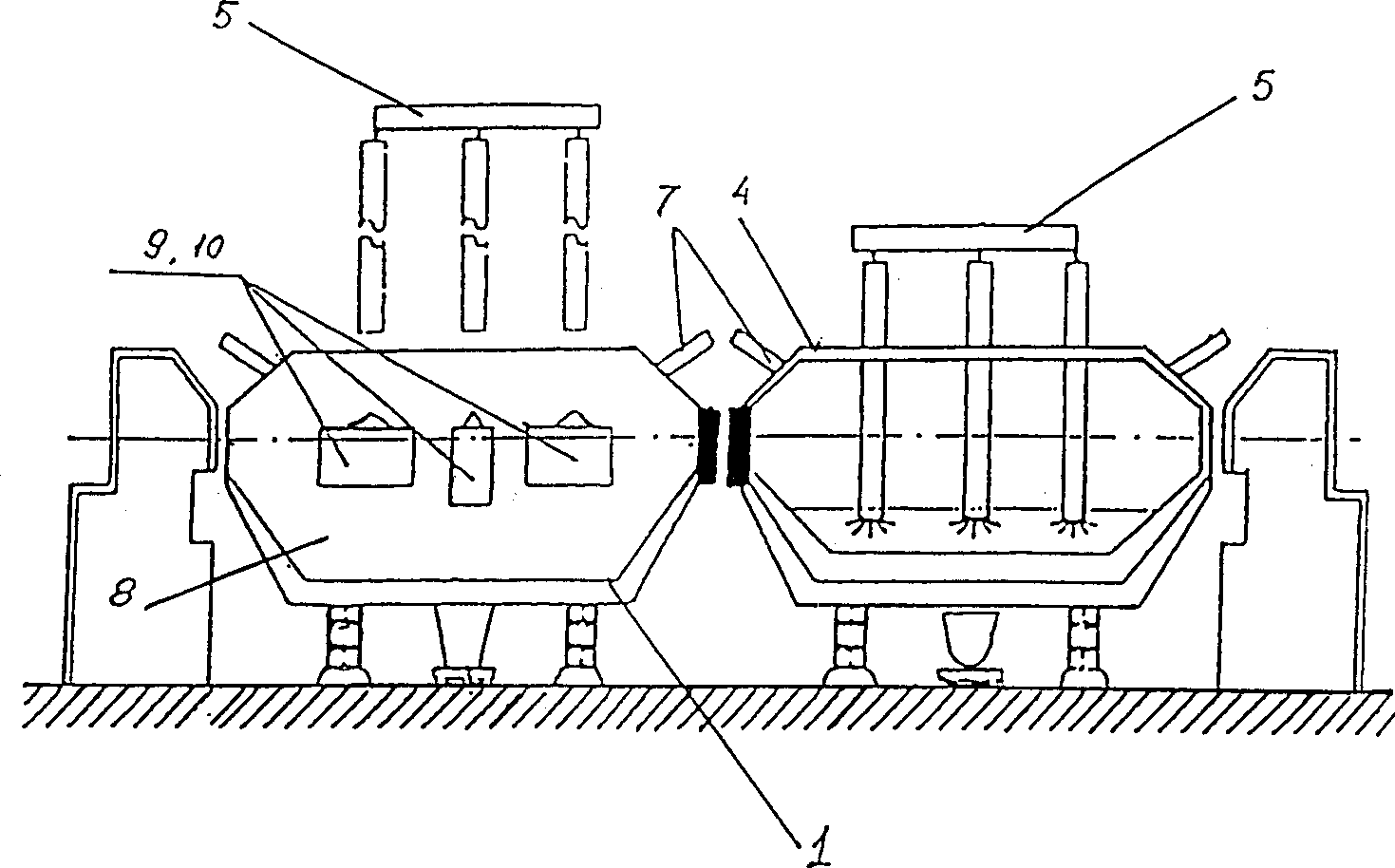

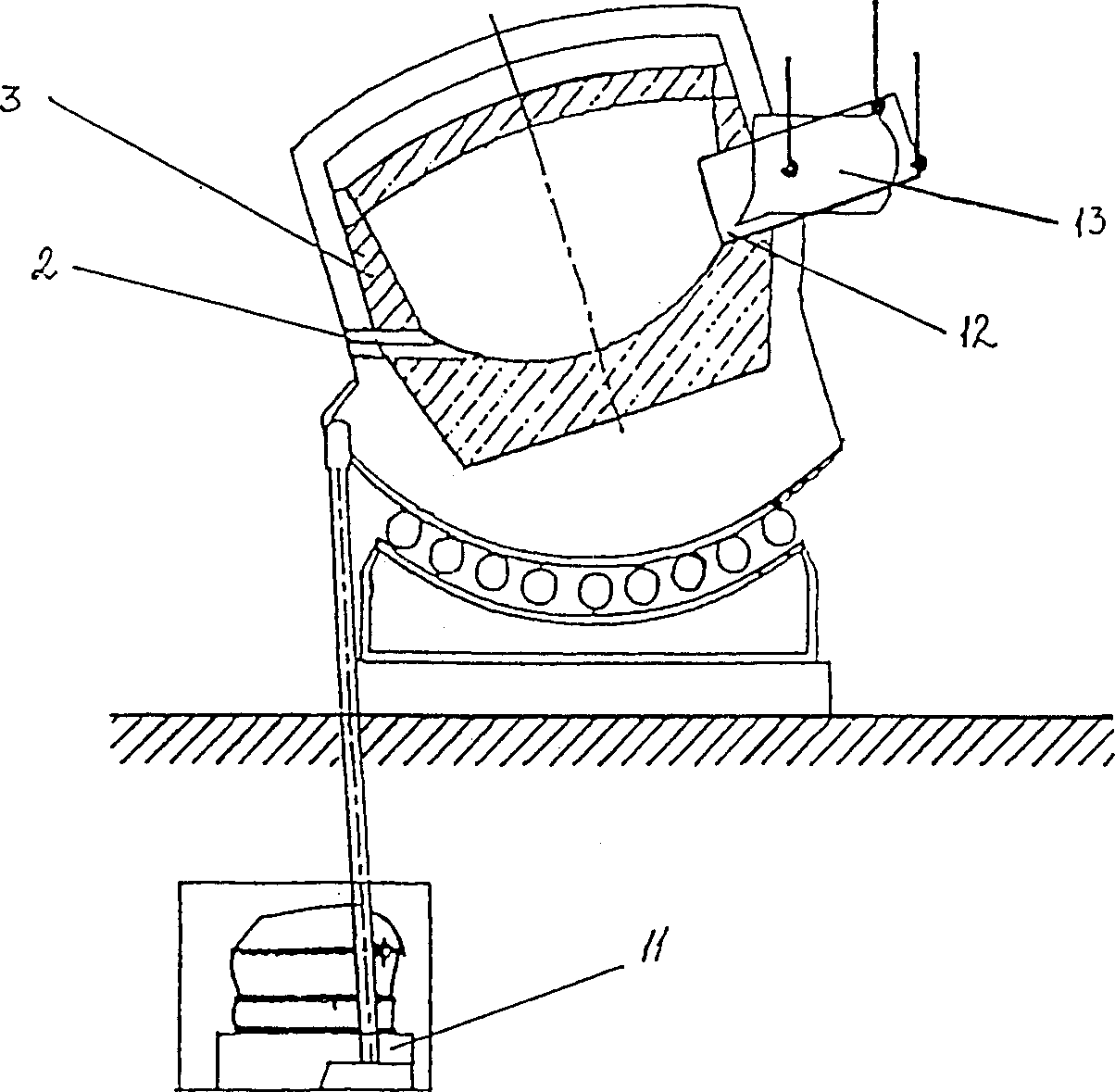

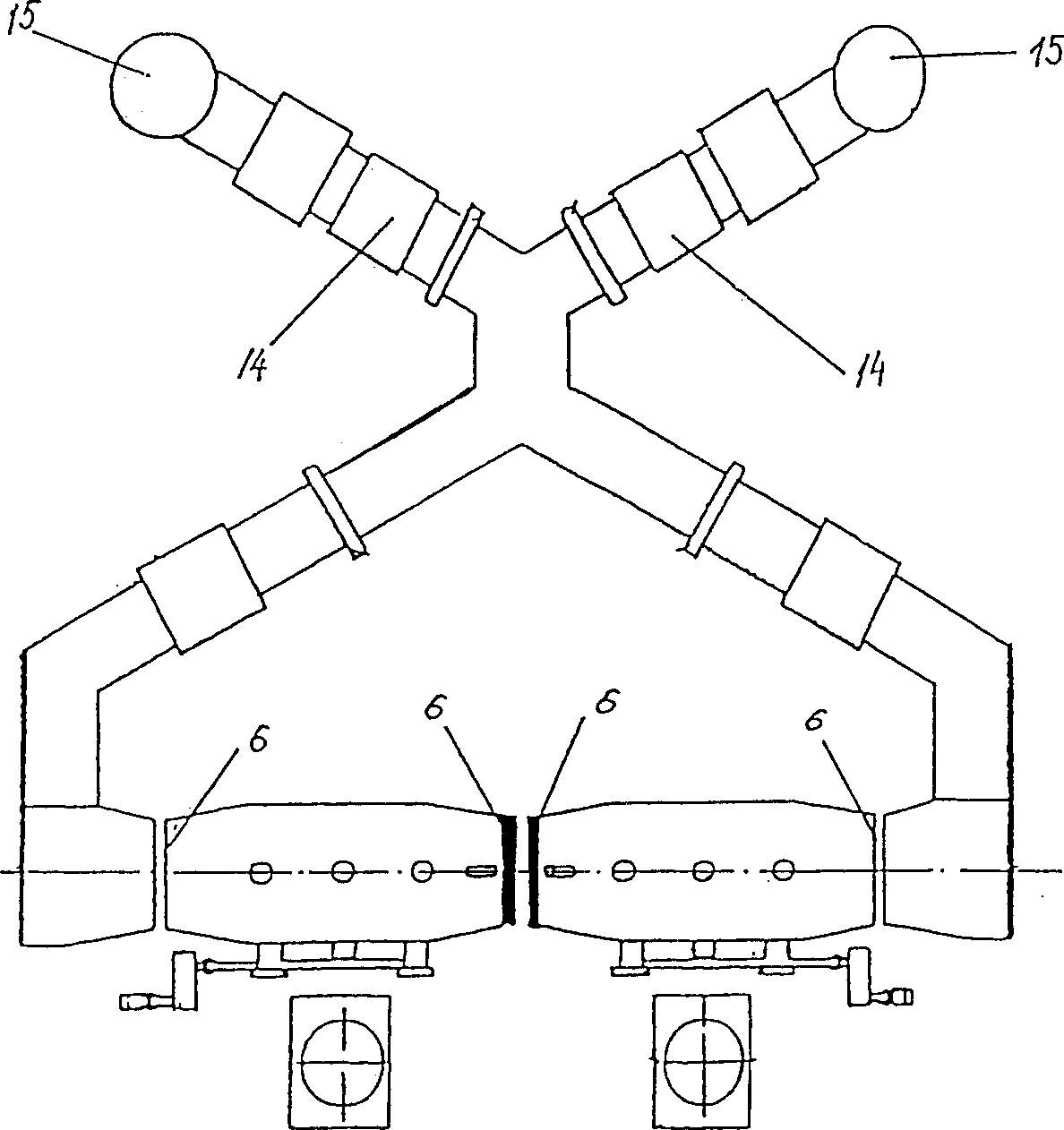

[0026] Such as figure 1 , figure 2 with image 3 As shown, the double-chamber steelmaking device of the present invention includes two smelting chambers, and the tops of the smelting chambers communicate with each other. Each smelting chamber includes a furnace 1, and the molten steel outlet 2 of the furnace 1 is arranged on one side of the rear wall 3 of the smelting chamber; Wall 6, the top of side wall 6 is also equipped with gas-oxygen burner 7 for secondary combustion of carbon monoxide contained in the waste gas, front wall 8, two feed ports 9 installed on the front wall 8, so The horizontal height of the lowest part of the feed inlet 9 is +9400mm, and it is located between the two feed inlets for processing the slag treatment port 10. Each melting chamber has a smelting chamber that can rotate the melting chamber around its horizontal axis. A device 11 with which the melting chamber can be inclined to an angle of 45° relative to its horizontal axis to the front or r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com