Method for recycling scrap containing aluminium-lithium-type alloys

A technology of aluminum alloy and scrap, applied in chemical instruments and methods, metallurgical equipment, improvement of process efficiency, etc., can solve problems such as restricting economic development and affecting the overall economy of Al-Li alloys.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] 2 tons of Alloy 2098 milling chips ("scrap") were introduced into IDEX through a screw feeder Furnace to degrease. The density of this waste is 0.3t / m 3 . A magnetic sensor was used at the entrance to the furnace to minimize occasional magnetic contamination.

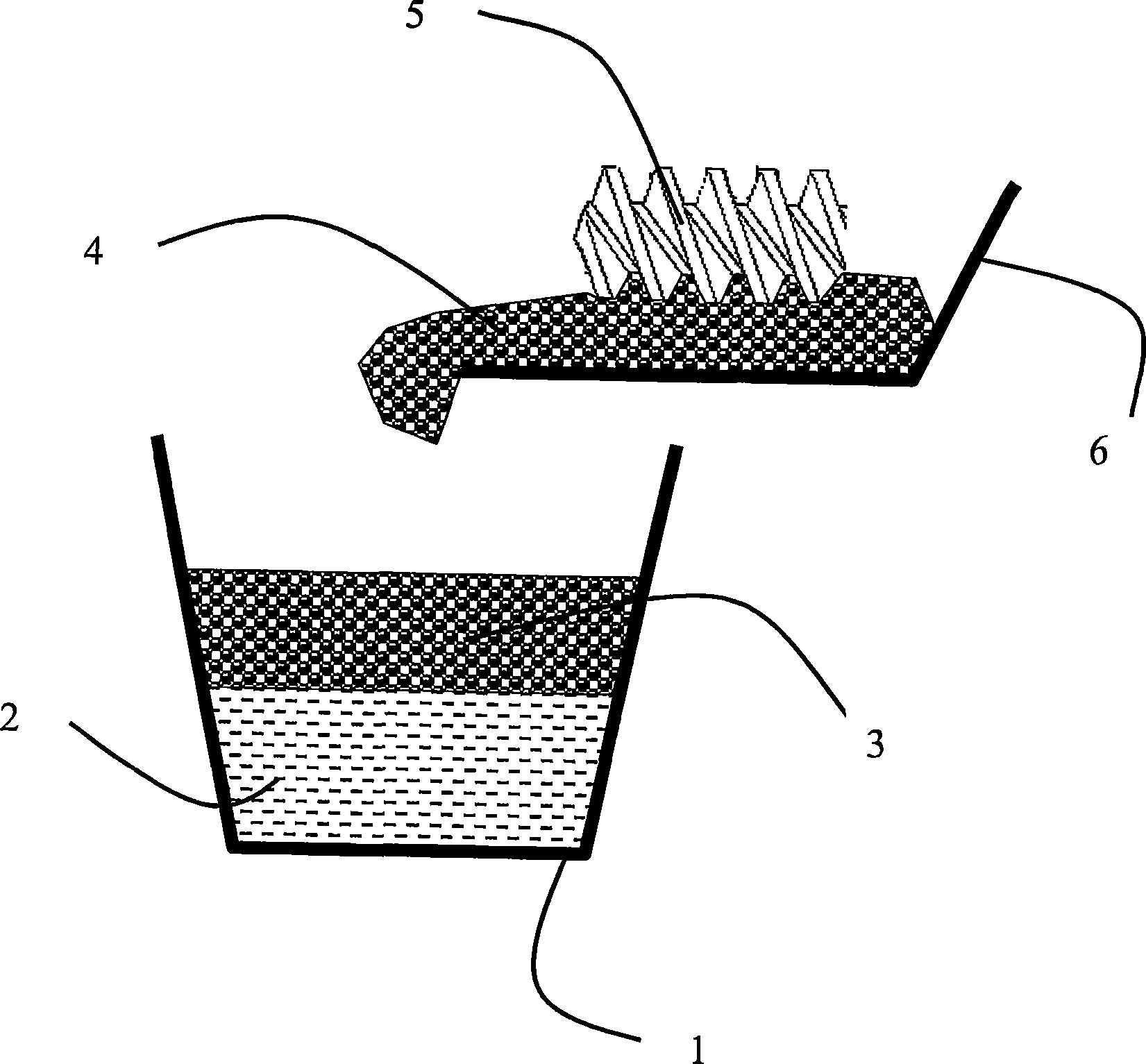

[0067] In an induction furnace with a capacity of 6 tons (frequency of supply current: 70 Hz), a bed of liquid metal was prepared from 3 tons of bulk scrap of alloy 2098 (for other similar melting tests and continuous casting operations, before using The residue of the casting acts as a bed of liquid metal ("residue metal")). The temperature of the liquid metal bed is adjusted to between 700 and 780°C. Then 2 tons of waste were added at a flow rate of 6 tons / hour. Obtain a floating layer with a static thickness of 800mm. Argon was added during this loading step for some experiments. The conditions for all experiments are summarized in Table 1. When the waste was fully loaded, the surface of the liquid m...

Embodiment 2

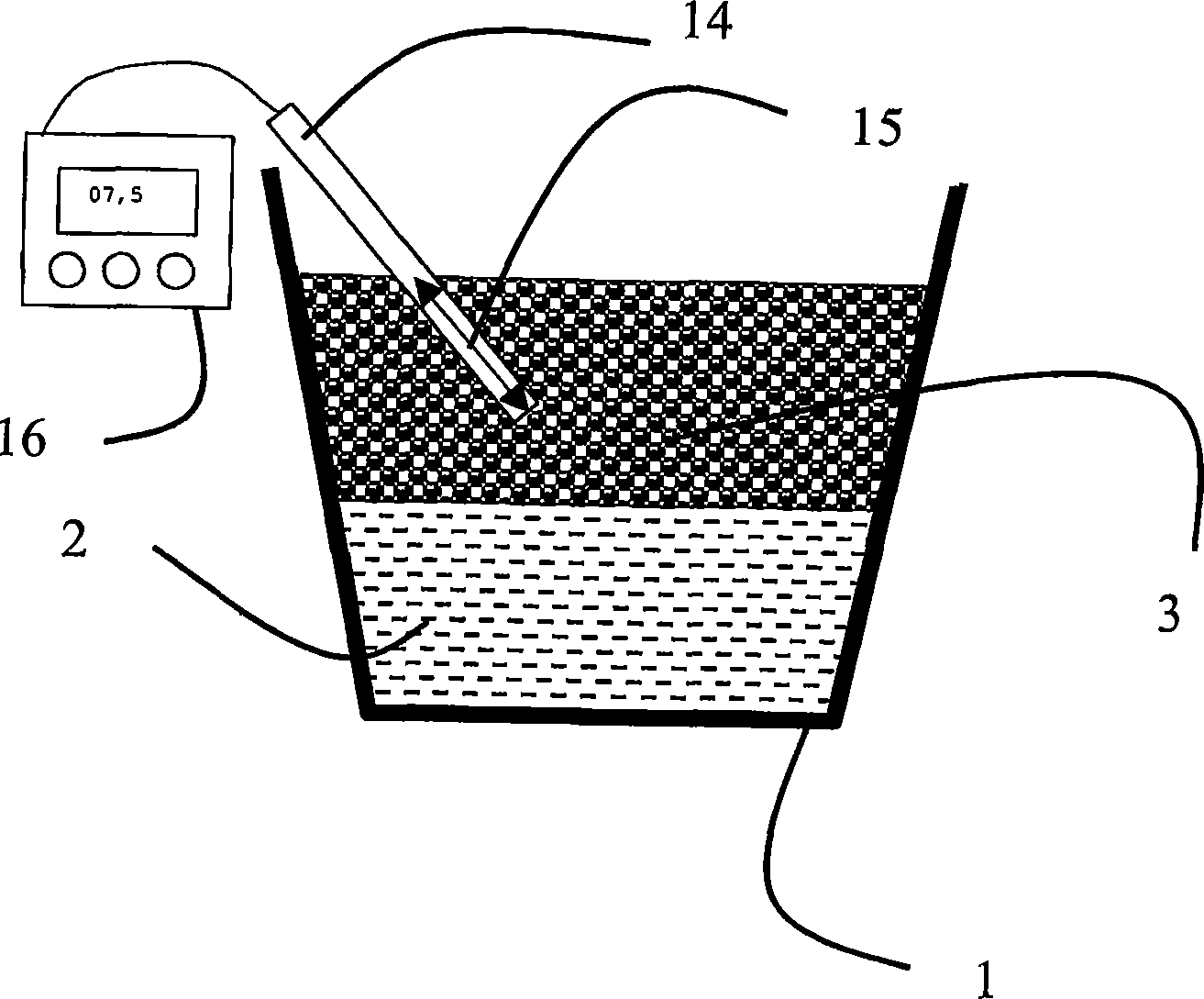

[0078] In order to better understand the protective effect of the floating layer above the liquid metal in the present invention, the oxygen content in the floating layer was measured by sensors and special devices. Figure 2 schematically illustrates the method used. A gas sampling rod (14) is inserted into the floating layer (3) to a predetermined depth (15). After insertion, the oxygen content is measured at a predetermined time (t1) by means of a gas analyzer (16). This time after insertion may affect the results of the measurements, since the insertion of the rod into the slick will locally disturb the composition of the atmosphere. The results obtained are given in Table 3. It should be noted that an effect on the oxygen content was observed when the rod was inserted to a depth of 50 mm. For an insertion depth of 120 cm and 7 min after insertion, the oxygen content can reach less than one-third of the original. These measurements show the effect of the floating layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com