Wet nonwoven fabric for hydrocarbon trap of gasoline engine air filter, and manufacturing method thereof

A technology for air filters and gasoline engines, applied in fuel air filters, textiles and papermaking, etc., can solve the problems of not being able to apply hydrocarbon trap products, improve adsorption/desorption capacity, prevent release, and improve performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1-6 and comparative preparation Embodiment 1-4

[0111] Using the configuration shown in Table 1 below, powdered activated carbon was prepared for the manufacture of a wet-laid nonwoven fabric for a hydrocarbon trap of an air filter for a gasoline engine.

experiment Embodiment 1

[0112] Experimental Example 1: Activated Carbon Performance Test of Powdered Activated Carbon

[0113] In order to perform the adsorption / desorption performance test on the powdered activated carbon prepared in each preparation example and comparative preparation example, it was baked at 110° C. for 3 hours before the test, and was heated at room temperature by using the standard jig used for the test. 500ml of activated carbon was filled under normal pressure (25°C±2°C, 1 atm) and 50±5%RH. Then, when loading 250cc / min N 2 After gas and 250 cc / min of butane gas, the above-mentioned activated carbon was subjected to a measurement until saturation, and then it was purged at 25.5 l / min to a minimum mass. The results of the above steps are shown in Table 1 below.

[0114] [Table 1]

[0115]

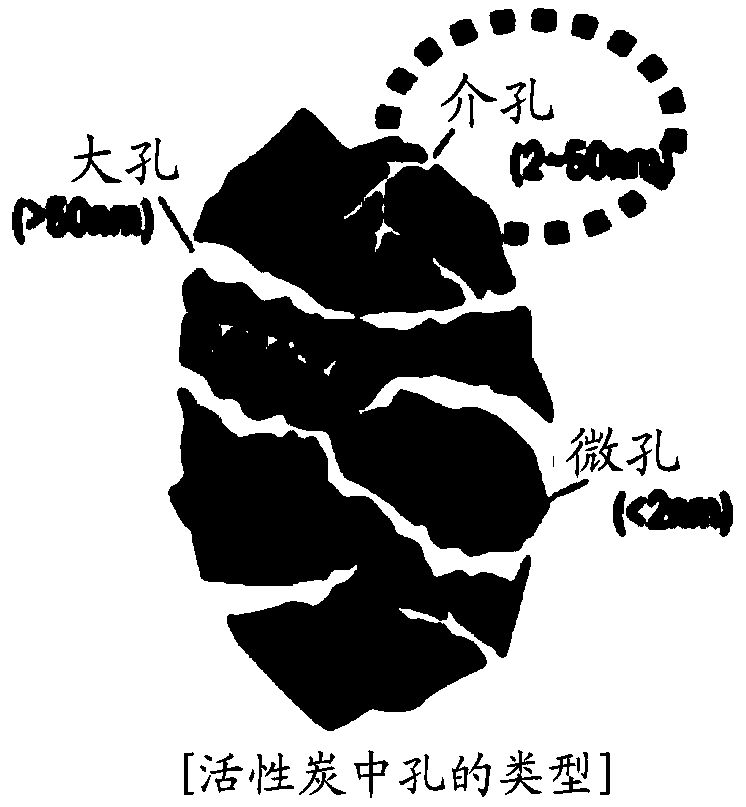

[0116] Referring to the activated carbon performance test (experimental example 1) of the above-mentioned powdery activated carbon, it can be seen that because the specific surface area...

Embodiment 1-4

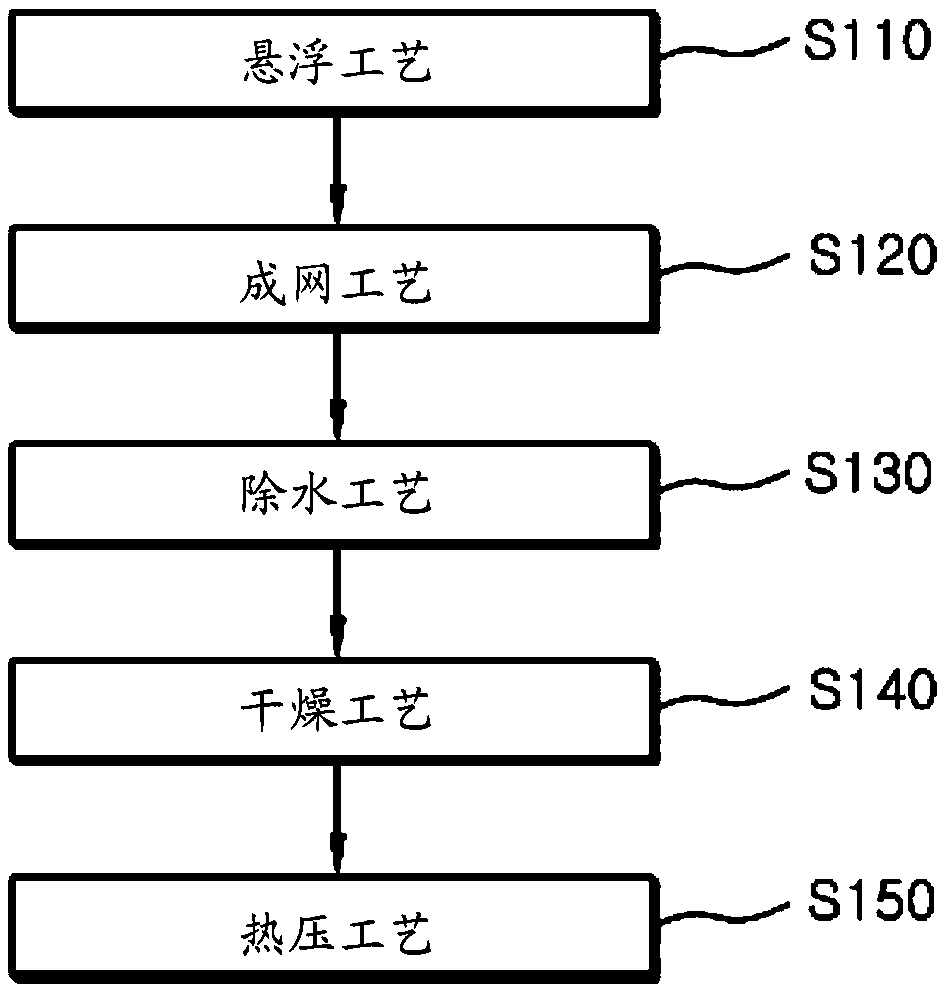

[0125] The base materials used in these examples were as follows: 340 g / m 2 powdered activated carbon; 15g / m 2 pulp; 80g / m at 110°C 2 The melting point of fine fibers (10μm); 1.3g / m 2 waterproofing agent; 45g / m 2 Carbon binders (Hercopuls from Ashland Co. TM 125); and 20g / m 2nonwoven fabric support. Additionally, other additives were used in these examples. By mixing the above-mentioned base materials, the base materials are subjected to a suspension process S110 of preparing a suspension, and then a net-type product is formed through a net-forming process S120. Then, after passing through the water removal process S130, the net product is dried in a drying process S140. Here, among the additives, a carbon fixer or a dehydration enhancer was used in Examples 1-4, respectively, while containing a base material. The carbon fixer used here was SY CHEM SB-50N (manufactured by SY CHEM Co.), and the dehydration enhancer was SY CHEM C-100 (manufactured by SY CHEM Co.). Accor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com