Hot-rolled steel sheet for production of non-oriented magnetic steel sheet and process for manufacturing same

A technology for hot-rolled steel sheets and electromagnetic steel sheets, which is applied in the manufacture of inductors/transformers/magnets, manufacturing tools, and magnetic properties of inorganic materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

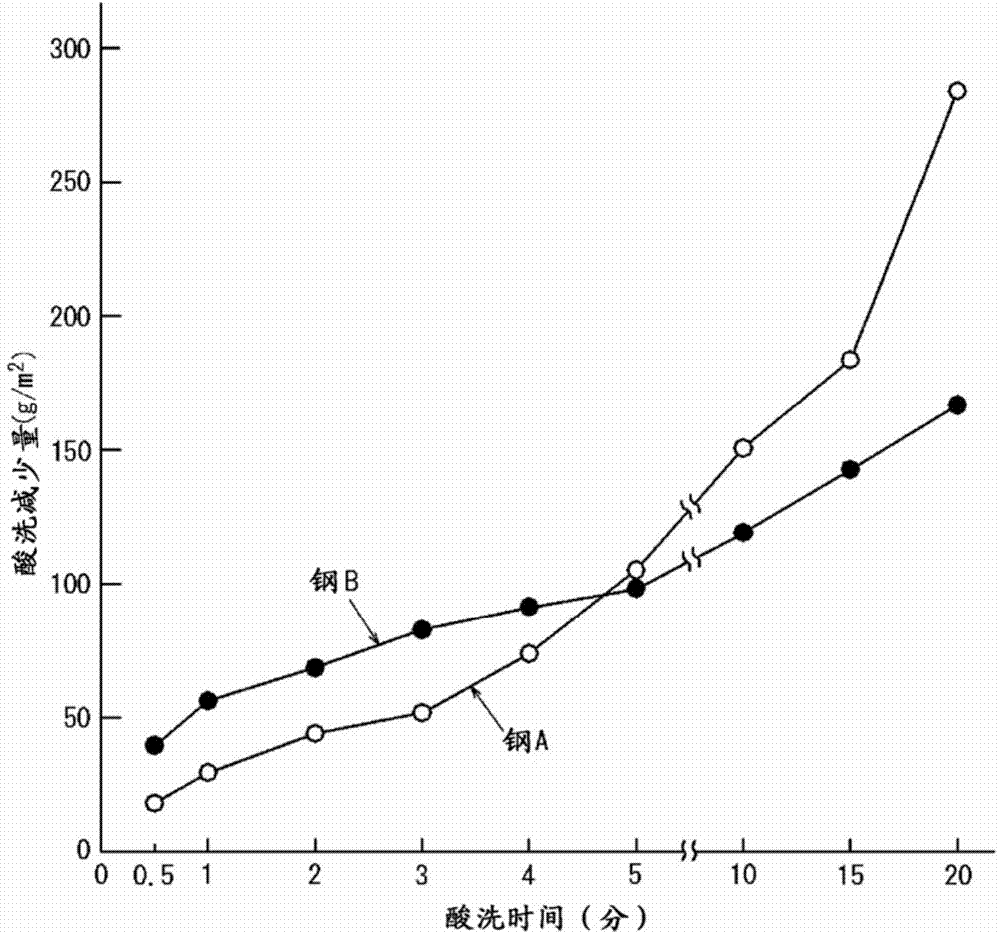

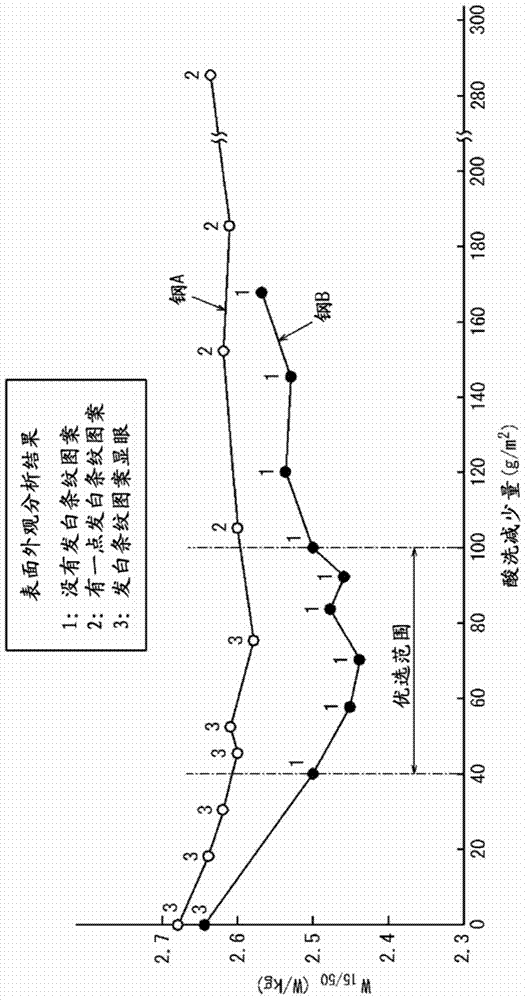

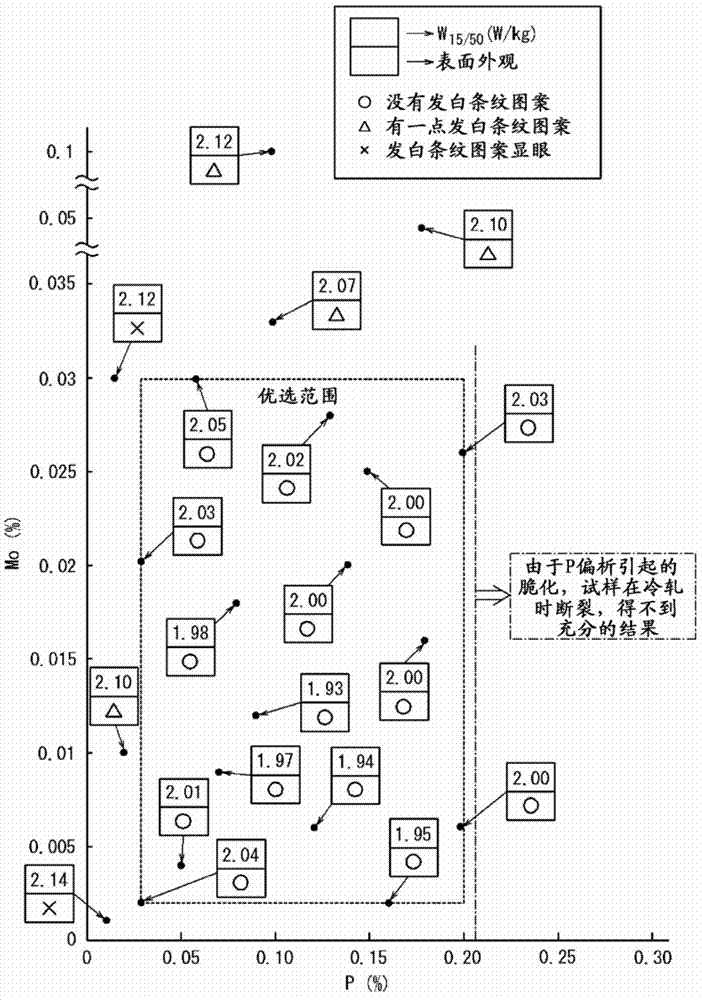

[0096] The molten steel obtained by blowing in a converter was subjected to a degassing treatment, followed by casting, and a slab having the composition shown in Table 1 was produced. Thereafter, after heating the slab at 1130° C.×1 h, it was hot-rolled to a thickness of 2.0 mm at the final hot-rolling finish temperature and post-hot-rolling coiling temperature conditions shown in Table 2 to obtain a hot-rolled steel sheet. Next, at 100% N 2 The hot-rolled sheets were annealed at 1000° C.×30 seconds in an atmosphere, pickled by immersion in a 7% HCl solution at 80° C. for 60 seconds, and then cold-rolled to the thicknesses shown in Table 2. Thereafter, at 20% H 2 -80%N 2 In the atmosphere, the final annealing was performed under the conditions of 1030° C.×10 seconds, and then the coating treatment was performed.

[0097] Epstein test pieces were cut out from the obtained non-oriented electrical steel sheet along the rolling direction and the direction at right angles to ro...

Embodiment 2

[0103] The molten steel obtained by blowing in a converter was subjected to a degassing treatment, followed by casting, and a slab having the composition shown in Table 3 was produced. Thereafter, after the slab was heated at 1100° C.×1 h, it was hot-rolled to a thickness of 1.6 mm under the conditions of the final hot-rolling finish temperature and the coiling temperature after the hot-rolling finish shown in Table 4. Next, at 100% N 2 The hot-rolled sheet was annealed in an atmosphere at 1000° C. for 30 seconds, and then pickled under the conditions of 7% HCl and 80° C.×60 seconds immersion, and then cold-rolled to the sheet thickness shown in Table 4. Thereafter, at 20% H 2 -80%N 2 In the atmosphere, final annealing was performed under the conditions of 1000° C.×10 seconds to perform coating treatment.

[0104] Epstein test pieces were cut out from the obtained non-oriented electrical steel sheet along the rolling direction and the direction at right angles to rolling, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com