Method for recovering scandium

A recovery method and process technology, which is applied to the field of effective recovery of scandium contained in nickel oxide ore, and can solve the problems of low grade and non-industrial recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

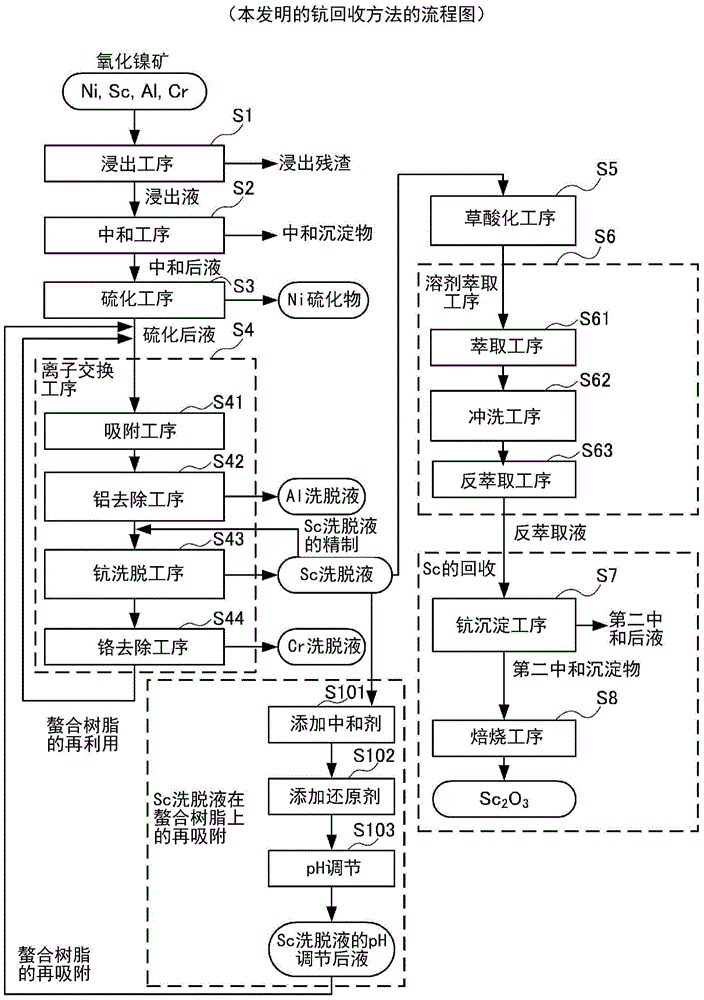

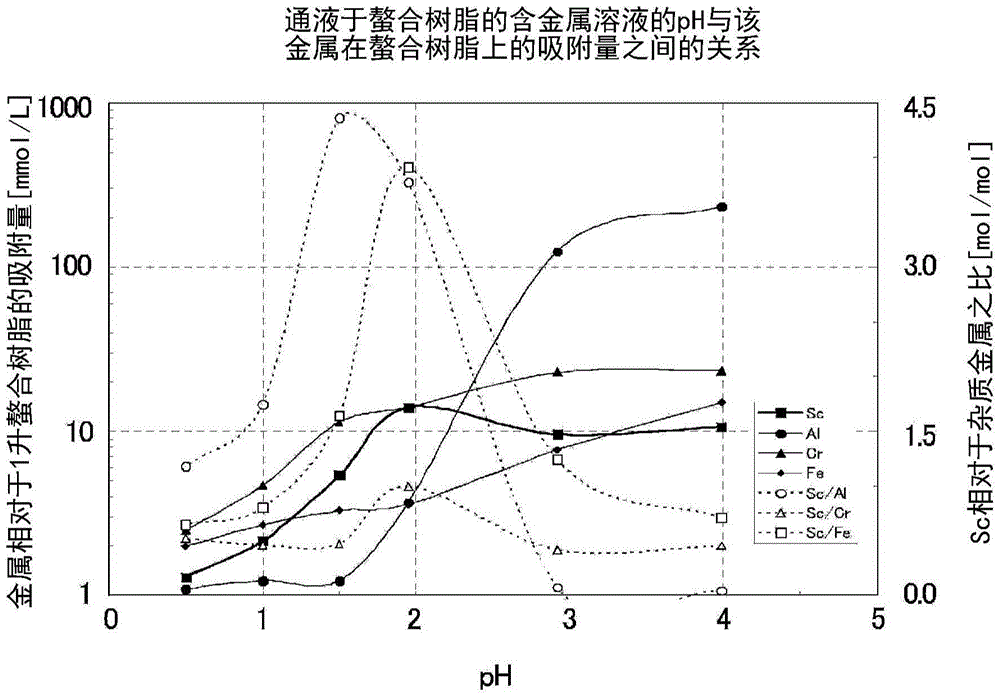

Method used

Image

Examples

Embodiment 1

[0118] is adsorbed on the removal of the chromium on the chelating resin

[0119] [Leaching process S1]

[0120] First, nickel oxide ore and concentrated sulfuric acid are put into a pressure cooker, and a slurry containing valuable metals such as scandium and nickel is formed after 1 hour at 245 ° C. From the slurry, solid-liquid separation containing the above-mentioned The leaching solution and leaching residue of valent metals.

[0121] [Neutralization process S2]

[0122] Then, calcium carbonate is added to the leaching solution to adjust the pH value to a range of 1 to 4 to obtain a neutralized precipitate and a neutralized solution. The neutralized solution contains valuable metals such as scandium and nickel, and the neutralized precipitate contains most impurities including aluminum.

[0123] [Vulcanization process S3]

[0124] Next, hydrogen sulfide gas is blown into the neutralized solution to separate nickel, cobalt, and zinc from the sulfided solution in the fo...

Embodiment 2

[0156] Re-adsorption of scandium eluate obtained in scandium elution step S43

[0157] The pH value of the scandium eluent obtained in Example 1 was adjusted to 3, and then a reducing agent was added so that the oxidation-reduction potential was calculated using the silver-silver chloride electrode as the value of the reference electrode to be -200mV or less, Then adjust the pH value to the range of 1-2.5 with sulfuric acid.

[0158] Then, under the same liquid-through conditions as in Example 1, the scandium eluent is passed through in the chelating resin of the same type as the above-mentioned Example 1 of 4mL, and then, adopting the same concentration as in Example 1 is 0.1N , 1N, and 3N sulfuric acid solutions were respectively washed and eluted to obtain a re-adsorbed aluminum washing solution, a re-adsorbed scandium eluent, and a re-adsorbed chromium eluent.

[0159] In the composition of the re-adsorbed aluminum cleaning liquid, Al was 3 mg / l, Sc was 0.24 g / l, and the...

Embodiment 3

[0163] Purification of scandium eluent

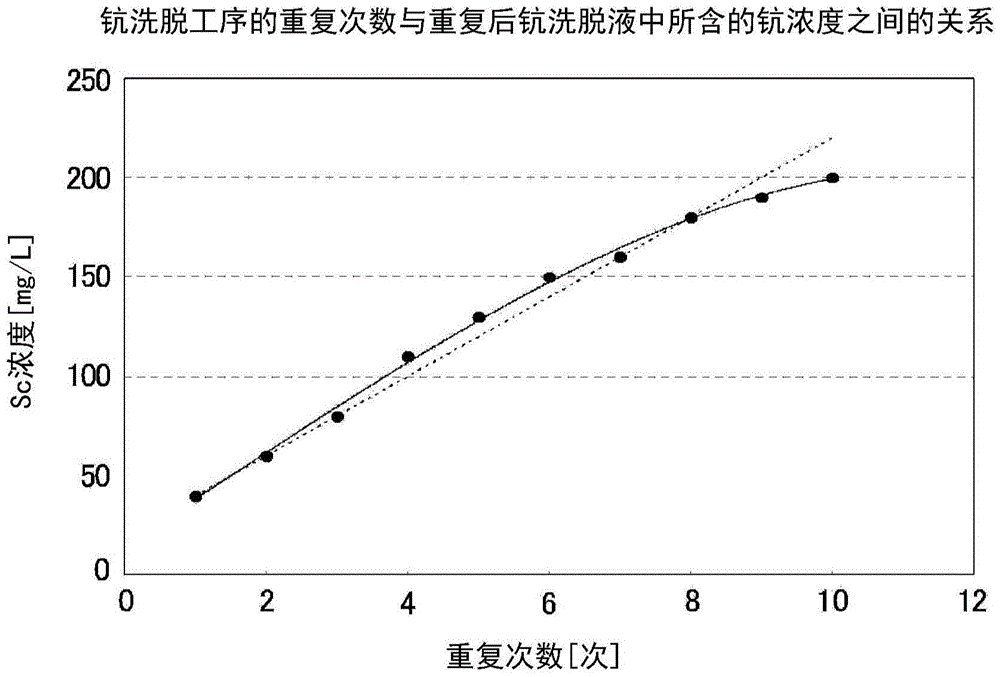

[0164] The scandium elution step S43 was repeated several times to refine the scandium eluent. That is, the scandium eluent obtained in the scandium elution step S43 was subjected to the scandium elution step S43 again, and after the scandium concentration was increased, the composition of the scandium eluate was measured again.

[0165] The results at this time are shown in image 3 middle. image 3 The abscissa of represents the number of times the scandium elution step S43 is repeated, and the ordinate represents the concentration of scandium contained in the scandium eluent after repetition. also, image 3 The dashed line is an approximate straight line based on the least squares method. Depend on image 3 It can be seen that the more times the scandium elution step S43 is repeated, the higher the recovered scandium concentration is, but even if a large number of excessive repetitions, the degree of rise of the recovered scand...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com