Method and device for treating steel slag

A processing method and technology for steel slag, applied in the field of metallurgy, can solve the problems of low hydration activity, good crystallization, unqualified stability of cement products, etc., and achieve the effect of improving the recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

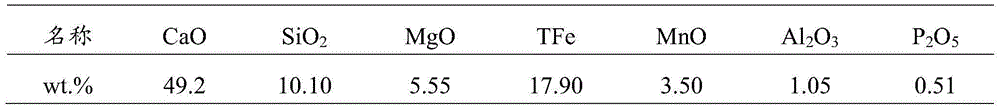

[0094] A steel plant with an annual output of 2.3 million tons of steel is equipped with two 120-ton converters, and the annual output of converter slag is about 280,000-300,000 tons after adopting the "three-stripping" process of molten iron. The main components (wt.%) of the converter slag after the "three stripping" of molten iron are shown in Table 1.

[0095] Table 1 Composition of converter slag (wt.%)

[0096]

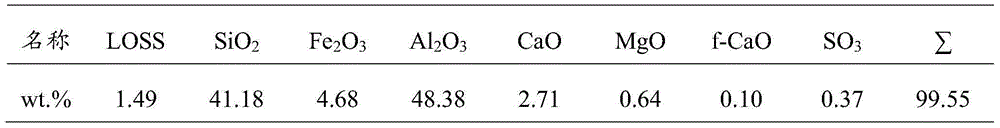

[0097] The fly ash from a coal-fired power plant was selected as the supplementary material of silicon-aluminum oxide. The chemical composition (wt.%) of the fly ash is shown in Table 2.

[0098] Table 2 Power plant fly ash composition (wt.%)

[0099]

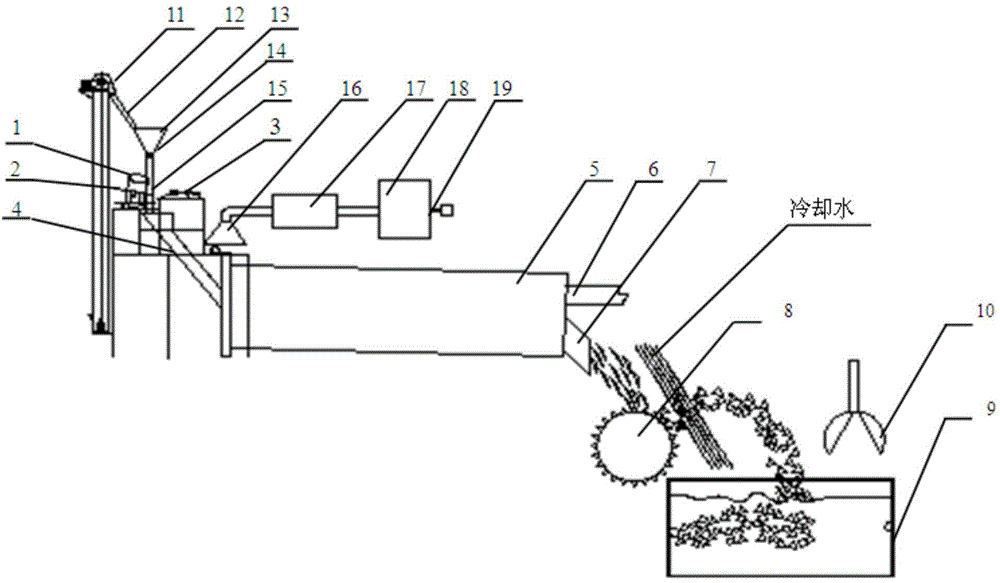

[0100] The steel slag produced from the converter is transported to the slag treatment site with a slag tank. The transportation time should be controlled within 30 minutes to ensure the temperature of the steel slag. The steel slag is poured into the receiving chute through the tilting mechanism. Due to ...

Embodiment 2

[0115] A steel plant with an annual output of 3 million tons of steel is equipped with three 1080 cubic meter blast furnaces and three 100-ton converters. After adopting the "three removal" process of molten iron, the annual output of blast furnace slag is about 1.4-1.6 million tons, and the annual output of converter slag About 360,000-400,000 tons. The main components (wt.%) of the converter slag after the "three stripping" of molten iron are shown in Table 3.

[0116] Table 3 Composition of converter slag (wt.%)

[0117]

[0118] Blast furnace slag is selected as the supplementary material of silicon-aluminum oxide, and the composition (wt.%) of blast furnace slag is listed in Table 4.

[0119] Table 4 Composition of blast furnace slag (wt.%)

[0120]

[0121] The steel slag produced from the converter is transported to the slag treatment site with a slag tank. The transportation time should be controlled within 30 minutes to ensure the temperature of the steel slag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com