N80 steel grade oil casing and preparation method thereof

A technology of oil casing and steel grade, which is applied in the field of N80 steel grade oil casing and its preparation, can solve the problems of N80 impact power difference and high energy consumption of N80 oil casing, so as to improve strength, reduce energy consumption, reduce The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

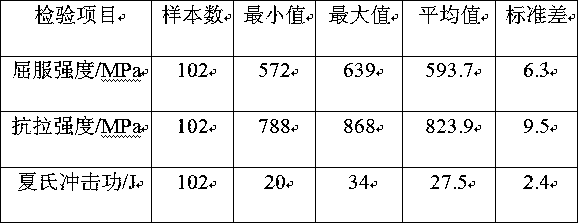

Examples

preparation example Construction

[0024] In one embodiment, the preparation method at least includes the following steps:

[0025] (1) Take scrap steel and microcrystalline graphite balls as raw materials, and obtain round billets after electric arc furnace smelting, ladle refining, and continuous casting;

[0026] (2) After the round tube blank is heated in a ring furnace, it is subjected to perforation treatment to obtain a capillary;

[0027] (3) The capillary tube is rolled to obtain a waste tube;

[0028] (4) After the waste pipe is subjected to micro-tension reduction and cooling treatment, thread processing is carried out to obtain N80 steel grade petroleum casing.

[0029] The following is a further explanation of the above preparation method:

[0030] Preferably, the mass ratio of scrap steel and microcrystalline graphite balls is (0.95~0.99): (0.05~0.01), and N80 steel grade petroleum casing has high strength and toughness through reasonable control of C, Mn, Cr, and V elements. Performance, scrap steel usuall...

Embodiment 1

[0040] Using scrap steel and microcrystalline graphite balls as raw materials, through 80t electric arc furnace smelting, ladle refining, and continuous casting, a round tube billet with a diameter of Φ160mm is produced. The weight percentage of its chemical composition is: C 0.28%, Si 0.25%, Mn 1.40 %, S 0.0015%, P0.008%, V 0.07%, Cr 0.15%, Al 0.025%, N 0.007%, Ni 0.03%, Cu 0.04%, the rest is Fe and unavoidable impurities.

[0041] After the round tube billet is heated by the ring furnace, pierced, rolled by the precision skew mill, micro-tension reduction, stepped cooling bed, and threaded, the N80 petroleum sleeve with an outer diameter of 139.7 mm and a wall thickness of 7.72 mm is made tube;

[0042] The weight percentage ratio of scrap steel to microcrystalline graphite balls is (0.95~0.99): (0.05~0.01).

[0043] In the heating process of the ring furnace, the temperature of the heating section is 1240~1280℃, the temperature of the soaking section is 1240~1260℃, and the discha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com