A scrap steel smelting ductile iron process with a recarburizer absorption rate of over 95%

A technology of recarburizer and absorption rate, which is applied in the field of scrap steel smelting ductile iron, can solve the problems of the influence of carburant addition, unsatisfactory, complicated process, etc., and achieve the improvement of purity, increase of profit space, and reduction of The effect of impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

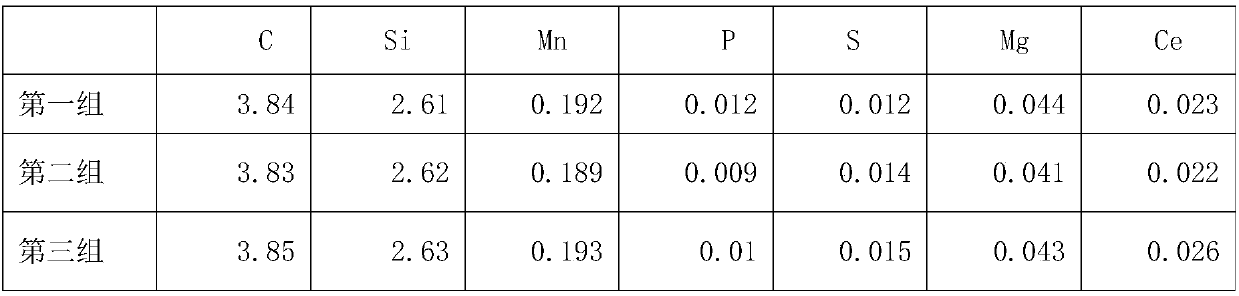

[0051] The melting equipment is a medium frequency induction furnace, and the full load capacity of each furnace is 1800KG. The raw materials include scrap steel, returned materials and recarburizers, and the scrap steel accounts for more than 65% in terms of the mass percentage of the raw materials. Scrap steel is the leftover steel scrap of our factory, and the returned furnace material is the recycled furnace material of our factory.

[0052] Selecting a reasonable particle size of the carburant can ensure the maximum absorption rate of the carburant. According to the size of the intermediate frequency induction furnace in our factory, a high-quality low-sulfur recarburizer with a particle size of 5mm in diameter is selected. In terms of mass percentage, the fixed C content in the carburant is >98.5%, the S content is <0.05%, and the total amount of carburant added is 45KG; the selection of high-quality and stable carburant is the premise to ensure the stable use of carbur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com