Patents

Literature

35results about How to "Guaranteed ferrite content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

More than 630 MPa level high strength steel bar and application method thereof in reinforced concrete

The invention discloses a more than 630MPa level high strength steel bar comprising the following components: by weight, 0.28%-0.38% of carbon, 0-0.35% of silicon, 0-0.90% of manganese, 0.80%-1.50% of Cr, 3.00%-4.00% of nickel, 0.40%-0.60% of molybdenum, 0-0.015% of P, 0-0.015% of sulfur, 0-2.0ppm of hydrogen, 0.10%-0.20% of vanadium, 0-0.025% of titanium, 0-0.20% of copper, 0-0.05% of aluminum, 0-0.50% of residual elements and the balance of Fe; the invention also designs an application method of the more than 630MPa level high strength steel bar in reinforced concrete; and the more than 630MPa level high strength steel bar has the advantages of high strength, steel saving, no pollution, good hardenability, low tendency to crack and low relaxation degree.

Owner:江苏森林建筑新材料股份有限公司

Production method for thermal treatment prestressed steel strand

The invention discloses a production method for a thermal treatment prestressed steel strand. According to the production method for the thermal treatment prestressed steel strand, AISI4340MOD steel is selected as raw materials and theAISI4340MOD steel comprises the following componentsby mass percent, 0.3 to 0.32 % of carbon, 0.18 to 0.36 % of silicon, 0.50 to 0.70 % of manganese, 0.90 to 1.10 % of chromium, 0.20 to 0.30 % of molybdenum, 0 to 0.02 % of phosphorus, 0 to 0.025 % of sulfur, 0 to 1.8 ppm of hydrogen, 0 to 0.40 % of nickel, 0 to 0.03 % of vanadium, 0 to 0.30 % of copper, 0 to 0.9 % of residual elements and the remaining is ferrum. The production method for the thermal treatment prestressed steel strand has the advantages of improving the strength and hardenability of the steel strand, enabling the steel strand to be not easy to craze, low in looseness, uniform and smooth in surficial galvanization.

Owner:TIANSHUN GROUP

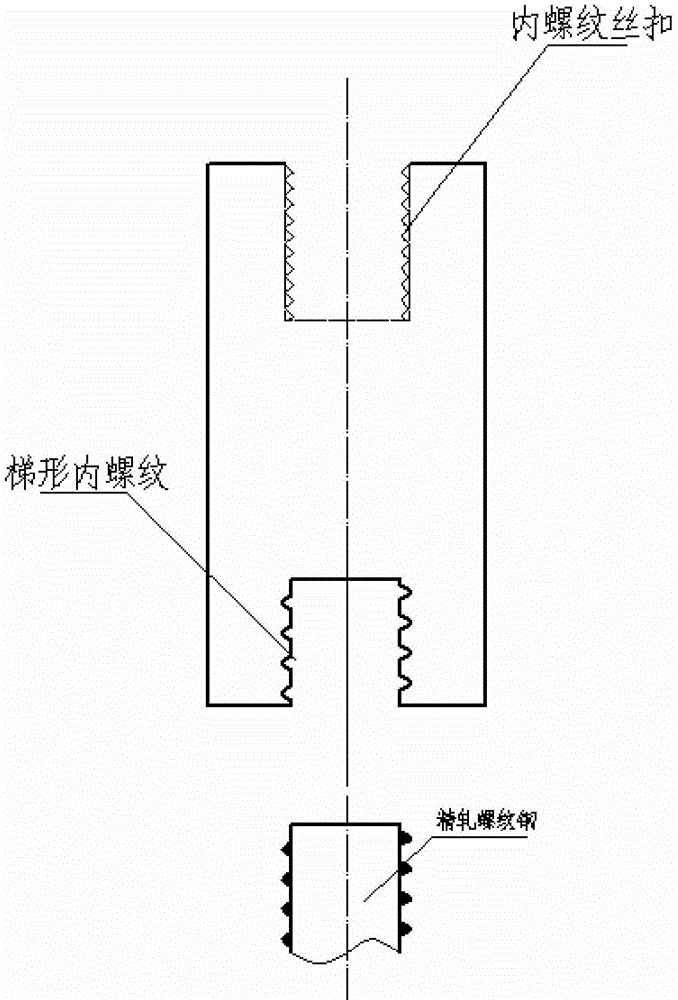

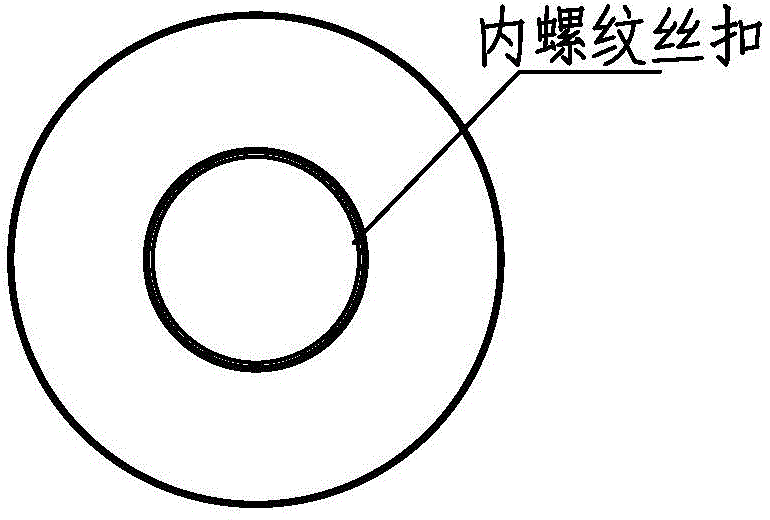

Processing method of above-600MPa-grade high-strength steel bar connection sleeve

ActiveCN103643124AImprove toughnessIncrease elasticityBuilding reinforcementsRebarMechanical engineering

The invention discloses a processing method of an above-600MPa-grade high-strength steel bar connection sleeve. The sleeve selects No.45 round steel as a raw material, and the No.45 round steel comprises 0.38-0.43wt% of C, 0.8-1.1wt% of Cr, 0.75-1.0wt% of Mn, 0.15-0.25wt% of Mo, 0.15-0.3wt% of Si, below 0.035% of S, below 0.035wt% of P, below 0.035wt% of N, and the balance Fe. The designed processing method of the above-600MPa-grade high-strength steel bar connection sleeve substantially improves the tensile strength and the elongation rate, guarantees the external diameter dimension and fineness of a steel tube, and reduces the friction stress between a tap and the inner wall of the sleeve.

Owner:江苏森林建筑新材料股份有限公司

Nickel-chromium alloy powder-coated steel bar manufacturing method

ActiveCN103643086AHigh strengthImprove safety and reliabilityMolten spray coatingNickel Chromium AlloysHeating furnace

The present invention discloses a nickel-chromium alloy powder-coated steel bar manufacturing method, which is characterized in that (1) the chemical components of the nickel-chromium alloy powder comprise, by weight, 0.2-3.3% of Re, 45-55% of Ni, 16-33% of Cr, 1.5-5.0% of Si, 0.25-0.5% of S, 0.2-1.5% of C, 10-16% of Fe, 0.8-10% of Mn, and 1-2% of composite rare earth; (2) the smelted steel bar is conveyed into a heating furnace to heat to achieve a temperature of 900-1000 DEG C; (3) the nickel-chromium alloy powder mixed according to a certain ratio is uniformly sprayed on the steel bar surface through a spraying gun; (4) the heated steel bar is conveyed into a quenching device; (5) the quenched steel bar is heated through a tempering heating furnace to achieve a temperature of 450-480 DEG C; and (6) the tempered steel bar is naturally cooled to achieve a room temperature. According to the invention, the nickel-chromium alloy is coated the steel bar surface so as to increase the wear resistance.

Owner:TIANSHUN GROUP

Making method of alloy coat coated prestressed steel wire

ActiveCN103643196AImprove machinabilityReduce rust generationMolten spray coatingFurnace typesHeating furnaceAlloy coating

The invention discloses a making method of an alloy coat coated prestressed steel wire. The method comprises the following steps: 1, preparing an alloy coat which is powdery; 2, sequentially carrying out pickling treatment phosphatization treatment and surface drying treatment of a prestressed steel wire rod; 3, sending the above obtained treated prestressed steel wire into a drawing machine, drawing to obtain the prestressed steel wire having required specifications and dimensions, and cleaning the prestressed steel wire; 4, sending the prestressed steel wire into a hot spraying device, uniformly spraying the surface of the prestressed steel wire with the prepared alloy powder by a spray gun, allowing the sprayed prestressed steel wire to an intermediate frequency heating furnace, and heating the prestressed steel wire to 550-570DEG C within 5-8s; and 5, allowing the prestressed steel wire to enter a quenching cooling device, cooling through a second cooling operation, air-cooling to room temperature, allowing the prestressed steel wire to a take-up machine, examining, and warehousing to obtain the alloy coat coated prestressed steel wire. The method increases the strength of the prestressed steel wire, further improves the wear resistance and the corrosion resistance of the prestressed steel wire, and prolongs the service life of the prestressed steel wire.

Owner:TIANSHUN GROUP

High-strength hot-rolled reinforcement bar of 830 MPa level, and production technology thereof

ActiveCN103484780AAvoid excessive corrosion rate and hardnessStrong hysteresis fracture resistanceRebarDuctility

The invention relates to a reinforcement bar and a production technology thereof, in particular to a high-strength hot-rolled reinforcement bar of the 830 MPa level, and a production technology of the reinforcement bar. The reinforcement bar comprises the following chemical components by weight: 0.38 to 0.43% of C, 0.7 to 0.9% of Cr, 0.6 to 0.8% of Mn, 0.15 to 0.25% of Mo, 0.2 to 0.3% of Si, 1.6 to 2% of Ni, 0.035% of S, 0.035% of P, 0.035% of N and the balance of Fe. The shear strength of the reinforcement bar can reach 830 MPa; the reinforcement bar has the advantages of high strength, good ductility, high lagging and fracture resistance, economy of steel material, underrelaxation, easiness in welding, high upset performance and the like, can enable carbide to dissolve fully and diffuse uniformly, and avoids that intercrystalline corrosion and pitting exceeding are caused due to intercrystalline separation of carbide.

Owner:江苏森林建筑新材料股份有限公司

Chromium-molybdenum low-alloy prestress aluminum-cladding steel wire manufacturing method

ActiveCN103643146AImprove toughnessIncrease elasticityFurnace typesHeat treatment furnacesPre stressManganese

The present invention discloses a chromium-molybdenum low-alloy prestress aluminum-cladding steel wire manufacturing method, wherein the chromium-nickel-molybdenum alloy structure steel is adopted as a billet material and comprises, by mass, 0.28-0.38% of carbon, 0-0.35% of silicon, 0-0.90% of manganese, 0.80-1.50% of chromium, 3.00-4.00% of nickel, 0.40-0.60% of molybdenum, 0-0.015%of phosphorus, 0-0.015% of sulfur, 0-2.0 ppm of hydrogen, 0.10-0.20% of vanadium, 0-0.025% of titanium, 0-0.20% of copper, 0-0.05% of aluminum, 0-0.50% of residual elements, and the balance of Fe. According to the chromium-molybdenum low-alloy prestress aluminum-cladding steel wire manufacturing method designed by the present invention, strength and toughness of the steel wire can be substantially increased, a corrosion resistance degree of the steel wire can be enhanced, and a service life can be prolonged.

Owner:TIANSHUN GROUP

Treatment process of aluminum-clad metal wire for high-strength shelf back mesh

The invention discloses a treatment process of an aluminum-clad metal wire for high-strength shelf back mesh. A selected steel blank comprises the following chemical components in percent by weight: 0.03-0.08% of C, 0.20-0.30% of Si, 0.20-0.46% of Mn, 0.85-1.0% of Cr, 0.16-0.22% of Mo, 0.015-0.030% of N, 0.05-2% of Cu, 0.02-0.10% of Ce, 0.02-0.10% of La, 0.04-0.05% of P, 0.03-0.04% of S, 0.01-0.25% of Nb, 0.18-0.36% of V, 4.8-5.9% of Al and the balance of Fe and impurities. During sectional material processing, the working procedures including feeding, drawing, electroplating, annealing, heat preserving, coating, acid pickling, drying and warehousing are sequentially performed. The treatment process of the aluminum-clad metal wire for the high-strength shelf back mesh, which is designed by the invention, has the advantages that the overall performance, such as mechanical strength and corrosion resistance, of alloy metal wires and back mesh finished-products can be improved, and the service life of the back mesh is greatly prolonged.

Owner:SUZHOU KESHENG STORAGE & LOGISTICS EQUIP

Alloy material for high-strength steel pull rod and treatment technology thereof

The invention discloses an alloy material for a high-strength steel pull rod and a treatment technology thereof. A nickel element is added; the strength and the toughness of the steel pull rod are improved; the hardenability and the corrosion resistance are improved; the atomic activities of a C element and an N element are improved so that an air mass formed by each atom can form a strong interaction with dislocation. Meanwhile, in the treatment process, a vacuum degasification furnace is used for performing degasification; die casting is protected by argon gas so that an air hole is avoided in a product and the quality of the product is further improved. The alloy material for the high-strength steel pull rod and the treatment technology thereof designed by the invention overcome the defect of the prior art and have the advantages of high strength, no pollution, good hardenability, difficulty to crack and low looseness.

Owner:TIANSHUN GROUP

Processing method for chrome molybdenum low alloy prestressed steel reinforcement connection joint

The invention discloses a processing method for a chrome molybdenum low alloy prestressed steel reinforcement connection joint. Chrome-nickel-molybdenum low alloy structural steel serves as a blank, the percentage by weight of nickel is controlled to range from 3.00% to 4.00%, and the percentage by weight of chrome is controlled to range from 0.80% to 1.50%; through hydrogen diffusion heat treatment, under the premise that the hydrogen content of the blank is lower than 2.0 ppm, the hydrogen content is further reduced, the situation that white point cracks of the blank and heat treatment stress induce hydrogen induced cracks and hydrogen induced delay cracks is avoided, the toughness, elasticity, abrasive resistance and impact resistance of the steel are improved, and the steel is compact. Through the processing method for the chrome molybdenum low alloy prestressed steel reinforcement connection joint, the strength, toughness and tension stress of the steel reinforcement connection joint can be greatly improved, the corrosion resistance of the steel reinforcement connection joint can be enhanced, and the service life of the steel reinforcement connection joint can be prolonged.

Owner:TIANSHUN GROUP

High-strength hot-rolled reinforcement bar of 830 MPa level, and production technology thereof

The invention relates to a steel bar and its production process, which is a 830MPa grade high-strength hot-rolled steel bar and its production process. The chemical composition in weight percentage is: C: 0.38-0.43%, Cr: 0.7-0.9%, Mn: 0.6- 0.8%, Mo: 0.15-0.25%, Si: 0.2-0.3%, Ni: 1.6-2%, S: <0.035%, P: <0.035%, N: <0.035%, and the balance is Fe. The steel bar yield strength of the present invention can reach 830MPa, has the advantages of high strength, good ductility, strong hysteresis fracture resistance, steel saving, low relaxation, easy welding, good upsetting performance, etc., and can fully dissolve carbides and evenly diffuse, It avoids the precipitation of carbides between grains and causes excessive intergranular corrosion and pitting corrosion.

Owner:江苏森林建筑新材料股份有限公司

Urea-class stainless steel pipe and production process thereof

The invention relates to a urea-class stainless steel pipe and a production process thereof. The urea-class stainless steel pipe comprises the following chemical components: 19.6 to 19.8 percent of Ni, 3.2 to 3.5 percent of Mo, 19.1 to 19.3 percent of Cr, 0.025 to 0.028 percent of C, 1.3 to 1.5 percent of Si, 1.7 to 1.9 percent of Mn, 0.03 to 0.05 percent of S, 0.035 to 0.037 percent of P, 0.03 to 0.05 percent of Cu, 0.012 to 0.016 percent of Co, 0.03 to 0.05 percent of O, 0.3 to 0.5 percent of Al, 0.07 to 0.09 percent of Nb, 0.001 to 0.003 percent of B, 0.03 to 0.05 percent of N and the balance of Fe. Due to two different procedures of heating and cooling, the steel pipe has excellent intercrystalline corrosion resistance and selective corrosion performance and has excellent strong plasticity.

Owner:江苏鑫常特材有限公司

AISI4340 prestress steel bar manufacturing method

The present invention discloses a AISI4340 prestress steel bar manufacturing method, wherein a AISI4340MOD steel is adopted as a billet material, the billet material is subjected to smelting and finish rolling to obtain a prestress steel bar forging stock with the required size, the prestress steel bar forging stock is sequentially subjected to a hydrogen diffusion heat treatment, rough processing, water cooling quenching and air cooling quenching, a polyethylene corrosion resistance coating is coated on the outer surface of the steel bar forging stock, and a polyethylene heat shrink sleeve is arranged outside the polyethylene corrosion resistance coating. According to the AISI4340 prestress steel bar manufacturing method designed by the present invention, the obtained AISI4340 prestress steel bar has characteristics of high strength, good ductility, strong delayed fracture resistance, steel saving, low relaxation, easy welding, good upsetting property and the like, and further has effects of substantially enhanced corrosion resistance sealing property, and effectively improved mechanical strength.

Owner:TIANSHUN GROUP

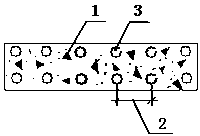

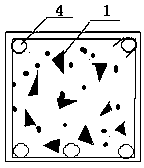

600 MPa-grade-and-above high strength steel bars and reinforced concrete application method thereof

ActiveCN103643147AImprove wear resistanceIncrease resistanceConstruction materialGirdersReinforced concreteRebar

The present invention discloses 600 MPa-grade-and-above high strength steel bars and a reinforced concrete application method thereof. According to the present invention, 0.4-0.65% by weight of Mn, 0.6-0.7% by weight of Cr, 0.15-0.3% by weight of Mo, 0.5-0.65% by weight of Ni, and 0.25-0.4% by weight of V are added to the steel bar component so as to improve strength, toughness, corrosion resistance, wear resistance and impact resistance of the steel bar, make the steel bar be compact, improve hardenability of the steel, and improve atom activities of the elements such as C and N, such that deformation and cracking can be reduced; and the application method of the diameter 6 mm and diameter 22 mm 600 MPa-grade-and-above high strength steel bars in the reinforced concrete has advantages of steel bar consumption reduction, carrying capacity increase, and crack extension resistance.

Owner:江苏森林建筑新材料股份有限公司

A method for manufacturing chromium-molybdenum low-alloy prestressed aluminum-clad steel wire

ActiveCN103643146BImprove toughnessIncrease elasticityFurnace typesHeat treatment furnacesChromium nickelManganese

The present invention discloses a chromium-molybdenum low-alloy prestress aluminum-cladding steel wire manufacturing method, wherein the chromium-nickel-molybdenum alloy structure steel is adopted as a billet material and comprises, by mass, 0.28-0.38% of carbon, 0-0.35% of silicon, 0-0.90% of manganese, 0.80-1.50% of chromium, 3.00-4.00% of nickel, 0.40-0.60% of molybdenum, 0-0.015%of phosphorus, 0-0.015% of sulfur, 0-2.0 ppm of hydrogen, 0.10-0.20% of vanadium, 0-0.025% of titanium, 0-0.20% of copper, 0-0.05% of aluminum, 0-0.50% of residual elements, and the balance of Fe. According to the chromium-molybdenum low-alloy prestress aluminum-cladding steel wire manufacturing method designed by the present invention, strength and toughness of the steel wire can be substantially increased, a corrosion resistance degree of the steel wire can be enhanced, and a service life can be prolonged.

Owner:TIANSHUN GROUP

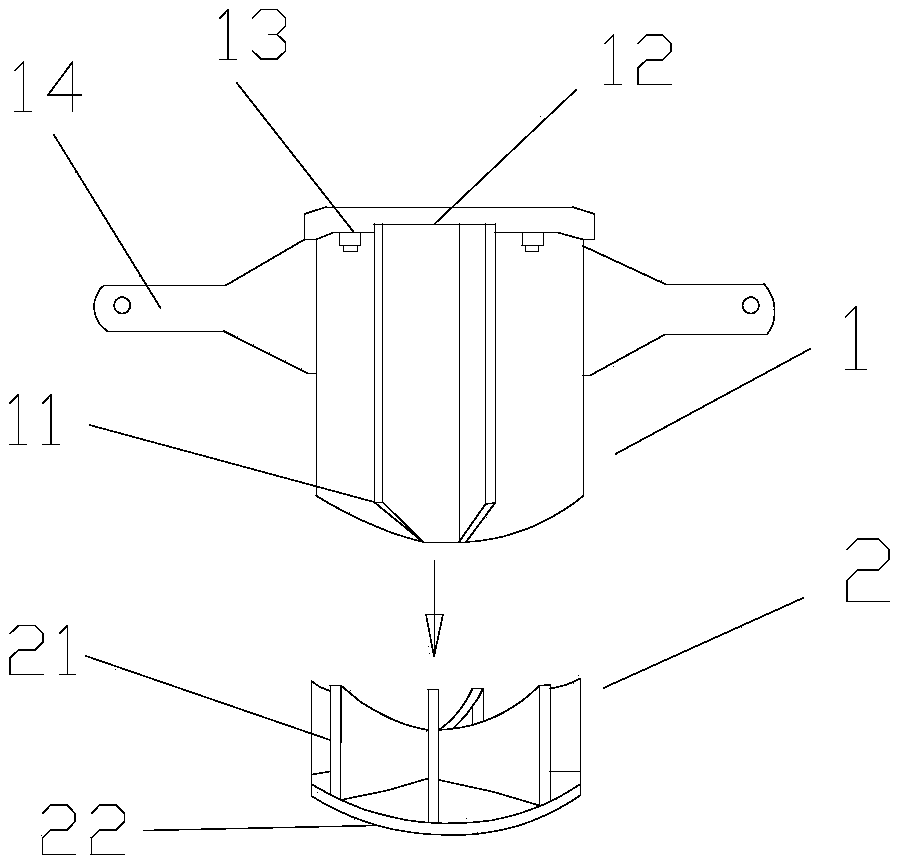

A spherical plate processing tooling

ActiveCN106282808BGuaranteed smoothnessGuaranteed ferrite contentFurnace typesAnti-corrosive paintsEngineeringMachine tool

The invention discloses a machining tool for a spherical plate. The tool comprises an upper mold and a lower mold, wherein the lower mold comprises a lower columnar structure defined through welding connection of sides of at least three lower rib plates and a seat plate arranged at the bottom of the lower columnar structure; a machining concave end surface is arranged at the top of the lower columnar structure, and the curve of the machining concave end surface is consistent with the radian of a curved surface of the to-be-machined spherical plate; the upper mold comprises an upper columnar structure defined through welding connection of sides of at least three upper rib plates and a top plate arranged at the top of the upper columnar structure; and a machining convex end surface is arranged at the lower end of the upper columnar structure and is matched with the machining concave end surface in radian. The smooth degree of the appearance of the plate can be guaranteed with the tool, assembly, electric welding and polishing in following processes can be reduced, the manufacturing period of the spherical plate can be shortened, and the manufacturing cost of the spherical plate can be saved.

Owner:JIANGSU DAJIN HEAVY IND

Preparation process of aluminum iron alloy wire

The invention discloses a preparation process of an aluminum iron alloy wire. The aluminum iron alloy wire is prepared by wrapping the outer surface of an alloy wire with aluminum, and the preparation process is prepared from the following chemical components in percentage by weight: 40-60% of aluminum, 35-55% of ferrum, 0.15-0.2% of carbon, 0.15-0.2% of silicon, 0.02-0.03% of phosphorus, 0.03-0.04% of sulfur, 0.04-0.05% of copper, 3.0-5.0% of cerium, less than or equal to 1.8PPm of hydrogen, less than or equal to 75PPm of nitrogen, less than or equal to 18PPm of oxygen and the balance being impurities. By using the preparation process of the aluminum iron alloy wire, designed by the invention, the quality can be greatly improved, the whole process is simple and easy to implement, and the yield of the aluminum is increased.

Owner:JIANGSU ZHENGDA FURNACE CHARGE

630 MPa-grade high-strength hot-rolled reinforced bar and production process thereof

Owner:江苏森林建筑新材料股份有限公司

A method for manufacturing high-yield unbonded prestressed steel rods

The invention discloses a manufacturing method of a high-yield non-bonding prestress steel bar. The steel bar has the advantages of bringing convenience to manual construction, being low in cost, high in strength, good in ductility and high in delayed fracture and saving steel, has ideal insulation effects, and can reduce environment pollution. According to the manufacturing method, steel structure anticorrosive paint is adopted, good mechanical performance and excellent anti-corrosion performance are achieved, stability for weather, oil water mixtures and the like is good, various colors can be mixed according to needs, the steel bar can have good visual effects after the steel anticorrosive paint is used, attractiveness and elegance in decoration are achieved, and cost can also be saved due to the fact that the paint has long anti-corrosion time.

Owner:TIANSHUN GROUP

600MPa grade-and-more high-strength building steel bar and duct piece application method thereof

ActiveCN103643145AAvoid intergranular corrosionAvoid uneven heatingCeramic shaping apparatusRebarHeating furnace

The invention discloses a 600MPa grade-and-more high-strength building steel bar and a duct piece application method thereof. The high-strength steel bar comprises 0.32-0.7wt% of C, 0.5-1.2wt% of Ni, 0.3-2.1wt% of Cr, 0.6-1.3wt% of Si, 0.4-0.8wt% of Mn, 0.6-0.7wt% of Cr, 0.12-0.28wt% of Mo, 0.3-0.55wt% of Ni, 0.2-0.3wt% of V, below 0.05wt% of S, below 0.02wt% of P, and the balance Fe. A production method of the high-strength steel bar comprises the following steps: 1, sending a steel bar into a heating furnace, and heating; 2, carrying out preliminary hot rolling of the steel bar; 3, putting the above obtained cooled steel bar in a tempering heating furnace, and heating to 500-550DEG C; 4, carrying out high pressure injection of the obtained heat-insulated steel bar with water or a quenching liquid; and 5, carrying out examination warehousing. The high-strength steel bar has the advantages of strong bearing capacity, security improvement, reduction of the consumption of the steel bar, and cost reduction.

Owner:溧阳市万兴特种建材有限公司

High-strength hot-rolled reinforcement bar of 730 MPa level, and production technology thereof

ActiveCN103484775BImprove atomic activityStrong interactionHeat treatment process controlChemical compositionCarbide

The invention relates to a steel bar and its production process, which is a 730MPa grade high-strength hot-rolled steel bar and its production process. The chemical composition in weight percentage is: C: 0.48-0.53%, Cr: 0.8-1.1%, Mn: 0.75- 1.0%, Mo: 0.15-0.25%, Si: 0.15-0.3%, S: <0.035%, P: <0.035%, N: <0.035%, and the balance is Fe. The steel bar yield strength of the present invention can reach 730Mpa, has the advantages of high strength, good ductility, strong hysteresis fracture resistance, steel saving, low relaxation, easy welding, good upsetting performance, etc., and can fully dissolve carbides and evenly diffuse, It avoids the precipitation of carbides between grains and causes excessive intergranular corrosion and pitting corrosion.

Owner:江苏森林建筑新材料股份有限公司

A kind of manufacturing method of AISI4340 prestressed steel bar

The present invention discloses a AISI4340 prestress steel bar manufacturing method, wherein a AISI4340MOD steel is adopted as a billet material, the billet material is subjected to smelting and finish rolling to obtain a prestress steel bar forging stock with the required size, the prestress steel bar forging stock is sequentially subjected to a hydrogen diffusion heat treatment, rough processing, water cooling quenching and air cooling quenching, a polyethylene corrosion resistance coating is coated on the outer surface of the steel bar forging stock, and a polyethylene heat shrink sleeve is arranged outside the polyethylene corrosion resistance coating. According to the AISI4340 prestress steel bar manufacturing method designed by the present invention, the obtained AISI4340 prestress steel bar has characteristics of high strength, good ductility, strong delayed fracture resistance, steel saving, low relaxation, easy welding, good upsetting property and the like, and further has effects of substantially enhanced corrosion resistance sealing property, and effectively improved mechanical strength.

Owner:TIANSHUN GROUP

A kind of aerial multi-point vertical steel bar connection node and its construction method

The invention discloses a midair multipoint vertical steel bar connecting joint which is made of number 45 round steel. The round steel comprises the chemical components, by weight, 0.38-0.43% of C, 0.8-1.1% of Cr, 0.75-1.0% of Mn, 0.15-0.25% of Mo, 0.15-0.3% of Si, 0.035% of S, 0.035% of P, 0.035% of N, and the balance Fe. The invention further discloses a construction method of the midair multipoint vertical steel bar connecting joint. The midair multipoint vertical steel bar connecting joint and the construction method thereof are simple and practical, simple in construction and capable of greatly improving the strength, the toughness and the tension stress of the steel bar connecting joint.

Owner:TIANSHUN GROUP

A method of manufacturing heat-treated prestressed steel strands

The invention discloses a production method for a thermal treatment prestressed steel strand. According to the production method for the thermal treatment prestressed steel strand, AISI4340MOD steel is selected as raw materials and theAISI4340MOD steel comprises the following componentsby mass percent, 0.3 to 0.32 % of carbon, 0.18 to 0.36 % of silicon, 0.50 to 0.70 % of manganese, 0.90 to 1.10 % of chromium, 0.20 to 0.30 % of molybdenum, 0 to 0.02 % of phosphorus, 0 to 0.025 % of sulfur, 0 to 1.8 ppm of hydrogen, 0 to 0.40 % of nickel, 0 to 0.03 % of vanadium, 0 to 0.30 % of copper, 0 to 0.9 % of residual elements and the remaining is ferrum. The production method for the thermal treatment prestressed steel strand has the advantages of improving the strength and hardenability of the steel strand, enabling the steel strand to be not easy to craze, low in looseness, uniform and smooth in surficial galvanization.

Owner:TIANSHUN GROUP

A processing method for connecting sleeves of high-strength steel bars above 600mpa

ActiveCN103643124BImprove toughnessIncrease elasticityBuilding reinforcementsRebarMechanical engineering

The invention discloses a processing method of an above-600MPa-grade high-strength steel bar connection sleeve. The sleeve selects No.45 round steel as a raw material, and the No.45 round steel comprises 0.38-0.43wt% of C, 0.8-1.1wt% of Cr, 0.75-1.0wt% of Mn, 0.15-0.25wt% of Mo, 0.15-0.3wt% of Si, below 0.035% of S, below 0.035wt% of P, below 0.035wt% of N, and the balance Fe. The designed processing method of the above-600MPa-grade high-strength steel bar connection sleeve substantially improves the tensile strength and the elongation rate, guarantees the external diameter dimension and fineness of a steel tube, and reduces the friction stress between a tap and the inner wall of the sleeve.

Owner:江苏森林建筑新材料股份有限公司

600mpa grade and above high-strength building steel bar and its segment application method

ActiveCN103643145BImprove solubilitySpread evenlyCeramic shaping apparatusTemperingHeat conservation

The invention discloses a high-strength building steel bar of 600 MPa level and above and an application method thereof. : 0.6-1.3%, Mn: 0.4-0.8%, Cr: 0.6-0.7%, Mo: 0.12-0.28%, Ni: 0.3-0.55%, V: 0.2-0.3%, S: <0.05%, P: < 0.02%, the balance is Fe, (1) put the steel bar into the heating furnace for heating; (2) carry out preliminary hot rolling of the steel bar; (3) put the cooled steel bar into the tempering furnace and heat it to 500-550 °C; Steel bars are sprayed with high-pressure water or quenching liquid; (5) inspection and storage are carried out; the invention has strong bearing capacity, improves safety, reduces the number of steel bars used, and reduces costs.

Owner:溧阳市万兴特种建材有限公司

A high-strength steel bar above 630mpa and its application method for reinforced concrete

Owner:江苏森林建筑新材料股份有限公司

A kind of manufacturing method of alloy coating coated prestressed steel wire

ActiveCN103643196BImprove high temperature oxidation resistanceReduce generationMolten spray coatingFurnace typesWire rodPre stress

The invention discloses a method for manufacturing prestressed steel wire coated with alloy coating. The method is carried out in the following steps: (1) Alloy coating is arranged, and the alloy coating is in powder form; (2) Prestressed steel wire is pickled sequentially with wire rod treatment, phosphating treatment and surface drying treatment; (3) send the treated prestressed steel wire into the wire drawing machine and draw it into the required specification and size, and then clean the prestressed steel wire; (4) send the prestressed steel wire into the thermal spraying equipment, and configure The good alloy powder is evenly sprayed on the surface of the prestressed steel wire with a spray gun, enters the intermediate frequency heating furnace, and heats the prestressed steel wire to 550-570°C within 5-8 seconds; (5) the prestressed steel wire enters the quenching cooling device, passes The second cooling process is cooled, and finally air-cooled to room temperature, then enters the wire take-up machine, inspects and puts into storage; thereby obtains the prestressed steel wire coated with alloy coating; the present invention increases the strength of the prestressed steel wire, and the wear resistance and resistance The corrosion resistance is further improved and the service life is increased.

Owner:TIANSHUN GROUP

A kind of manufacturing method of nickel-chromium alloy powder coating prestressed steel strand

ActiveCN103639402BHigh strengthImprove toughness and strengthMolten spray coatingRope making machinesWire rodChemical composition

The invention discloses a method for manufacturing a prestress steel strand coated with nichrome powder. The method for manufacturing the prestress steel strand coated with the nichrome powder comprises the following steps that (1) the nichrome powder comprises, by weight, 0.5-3.2% of Re, 48-54% of Ni, 18-32% of Cr, 1.6-5.5% of Si, 0.3-0.8% of S, 0.5-2.2% of C, 10-16% of Fe, 1.2-10% of Mn, and 1-2.5% of composite rear earth; (2) a plurality of wire rod steel wires are fed into a heating furnace; (3) the nichrome powder is evenly sprayed on the surfaces of the wire rod steel wires through a spray gun; (4) the wire rod steel wires are stranded through a stranding machine to form the steel strand which is of a steel wire rope shape; (5) the steel strand enters a quenching device; (6) the nichrome powder is evenly sprayed on the surface of the steel strand again through the spray gun; (7) the steel strand enters a layer winder to be packaged. According to the method for manufacturing the prestress steel strand coated with the nichrome powder, the strength, wear resistance and corrosion resistance of the steel strand are improved.

Owner:TIANSHUN GROUP

Super double-phase stainless steel tube and production process thereof

The invention discloses a super double-phase stainless steel tube and a production process thereof. The super double-phase stainless steel tube comprises the following components in percentage by weight: 7.6%-7.8% of Ni, 4.2%-4.5% of Mo, 22.1%-22.3% of Cr, 0.015%-0.018% of C, 0.045%-0.05% of Si, 0.3%-0.5% of Mn, more than 0 and not more than 0.02% of S, more than 0 and not more than 0.035% of P, 0.03%-0.05% of Cu, 0.012%-0.016% of Co, 0.03%-0.05% of O, 0.3%-0.5% of Al, 0.07%-0.09% of Nb, 0.001%-0.003% of B, 0.03%-0.05% of N and the balance being Fe. The production process can be used for sufficiently dissolving and uniformly dispersing carbide by virtue of two heating steps and two cooling steps, so that inter-crystalline corrosion and point corrosion caused by precipitation of the carbide among the crystals are avoided; moreover, the super double-phase stainless steel tube has good strong plasticity.

Owner:江苏鑫常特材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com