A spherical plate processing tooling

A spherical and tooling technology, applied in the direction of manufacturing tools, coatings, furnace types, etc., can solve problems such as inability to guarantee machining accuracy and good machining line shape, affecting production construction and progress, and inability to guarantee spherical shape, so as to avoid pitting corrosion. Exceed the standard, save production cost, improve the effect of anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

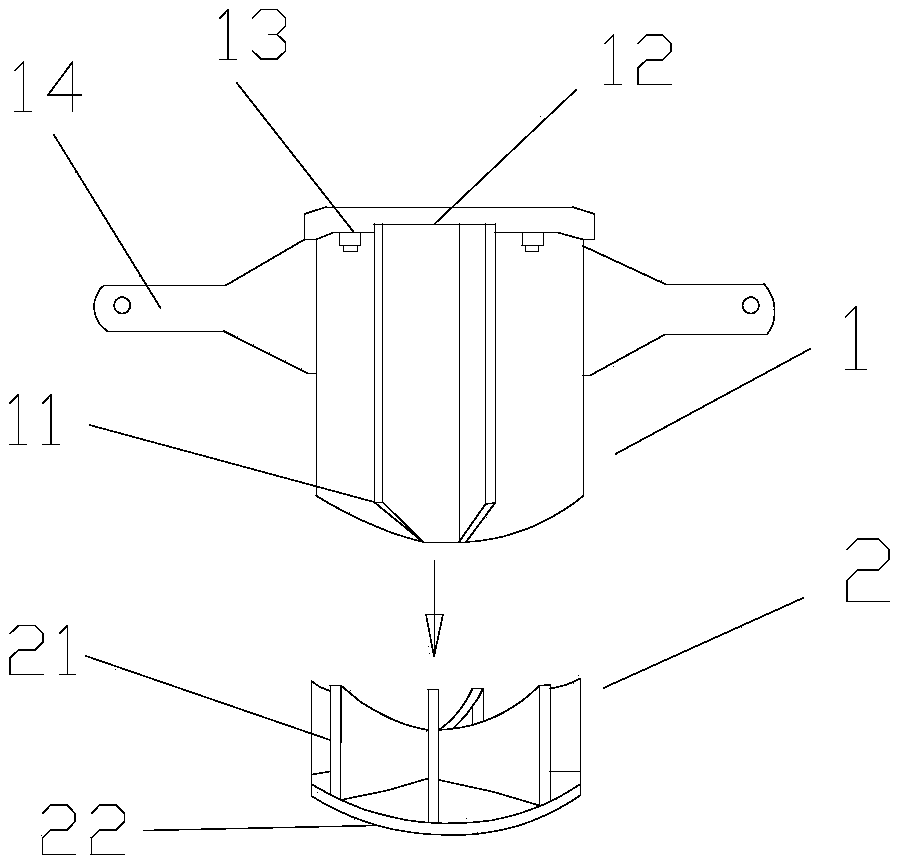

[0019] This embodiment provides a spherical plate processing tool, the structure is as figure 1 As shown, it includes an upper mold 1 and a lower mold 2. The upper mold 1 is welded by a top plate 12 and an upper columnar structure formed by welding one side of six upper ribs 11, and the lower mold 2 includes six lower ribs 21 One side of the plate is welded and connected to form a lower columnar structure and a seat plate 22 arranged at the bottom of the lower columnar structure. The top of the lower columnar structure is provided with a processed recessed end surface, and the curve of the processed recessed end surface is consistent with the curvature of the spherical plate to be processed; the upper mold includes Six upper ribs 11 are welded on one side to form an upper columnar structure and a top plate arranged on the top of the upper columnar structure. The lower end of the upper columnar structure is provided with a processed convex end surface, and the processed convex en...

Embodiment 2

[0029] The structure of this embodiment is the same as that of embodiment 1, and the difference is that the upper and lower ribs of this embodiment adopt the composition of high-strength alloy tool steel and the difference in surface coating. The high-strength alloy tool steel of this embodiment In terms of mass percentage, it includes the following specific components:

[0030] C: 0.95%, Ni: 12%, Cr: 0.91%, Mn: 5.3%, Si: 0.19%, Als: 0.024%, Mo: 0.37%, Nb: 0.18%, Cu: 0.91%, N: 0.09%, S: 0.032%, P: 0.05%, Ti: 0.18%, V: 0.03%, B: 0.003%, lanthanide rare earth: 1.3%, the balance is Fe;

[0031] The mass percentages of lanthanide rare earth components are: cerium: 25%, praseodymium: 14%, holmium: 19%, erbium: 15%, the balance is lanthanum, and the sum of the above components is 100%;

[0032] The manufacturing process of this high-strength alloy tool steel is as follows:

[0033] ⑴ Continuous casting billet heating: the continuous casting billet heating temperature is 1180℃, and the heat...

Embodiment 3

[0038] The structure of this embodiment is the same as that of embodiment 1, and the difference is that the upper and lower ribs of this embodiment adopt the composition of high-strength alloy tool steel and the difference in surface coating. The high-strength alloy tool steel of this embodiment In terms of mass percentage, it includes the following specific components:

[0039] C: 1.05%, Ni: 13%, Cr: 1.10%, Mn: 6.0%, Si: 0.23%, Als: 0.030%, Mo: 0.43%, Nb: 0.20%, Cu: 0.95%, N: 0.11%, S: 0.035%, P: 0.05%, Ti: 0.24%, V: 0.03%, B: 0.004%, lanthanide rare earth: 1.4%, the balance is Fe;

[0040] The mass percentages of the lanthanide rare earth components are: cerium: 27%, praseodymium: 17%, holmium: 22%, erbium: 16%, the balance is lanthanum, and the sum of the above components is 100%;

[0041] The manufacturing process of this high-strength alloy tool steel is as follows:

[0042] ⑴ Continuous casting billet heating: the continuous casting billet heating temperature is 1200℃, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com