Cold-rolled dual-phase steel DP780 and flexible production method thereof

A production method and dual-phase steel technology, which is applied in the field of cold-rolled dual-phase steel preparation, can solve problems such as cracking, and achieve the effects of good material fluidity, improved baking performance, and strong uniform deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

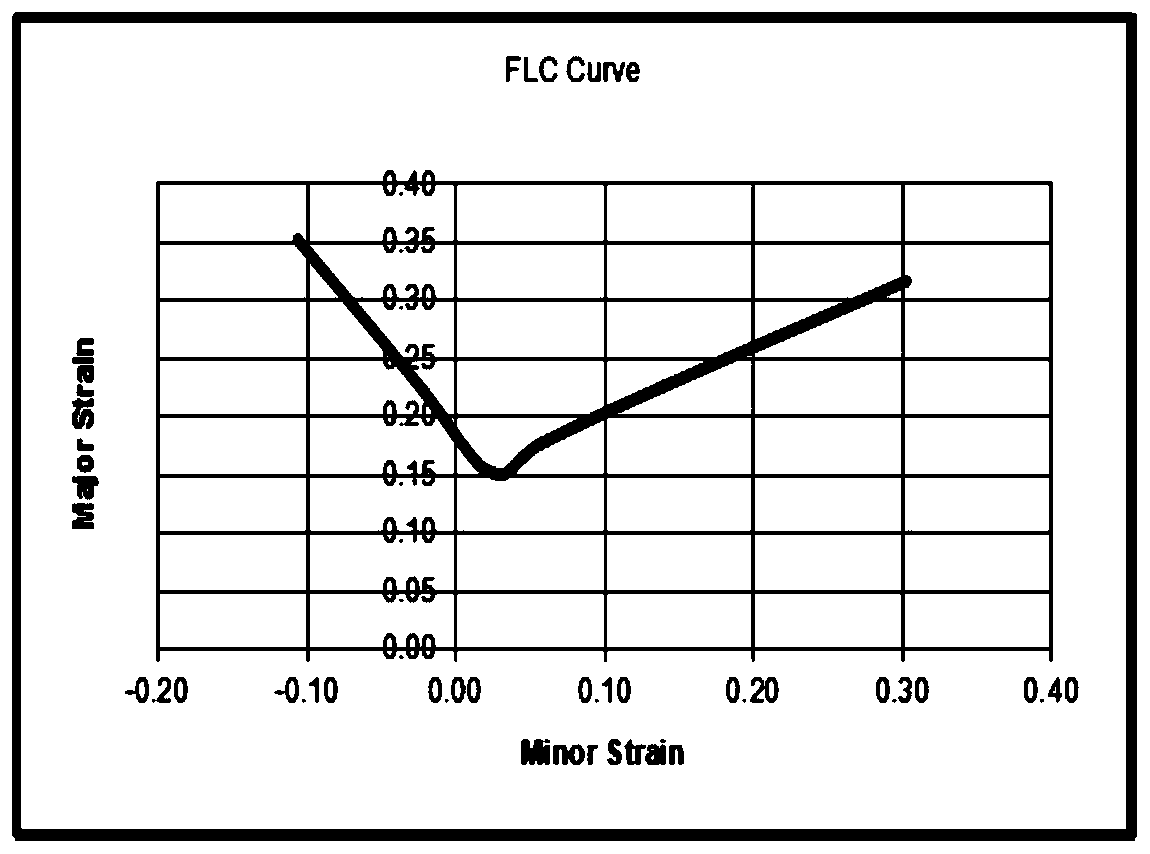

[0038] A cold-rolled dual-phase steel DP780, the production process is: molten steel pretreatment→converter smelting→external refining→continuous casting→hot rolling heating→rough rolling, finishing rolling→controlled cooling→coiling→cold rolling decoiling, Welding→pickling, cold rolling→continuous annealing→leveling→surface and performance inspection→packing→delivery; the composition of cold-rolled dual-phase steel DP780 is calculated by weight percentage: C: 0.15, Si: 0.20, Mn: 1.1, Ti: 0.02 , Cr: 0.10~0.20, Al: 0.04, P: ≤0.015, S: ≤0.010, and the rest are Fe and unavoidable impurities, that is, through the steelmaking-hot rolling-cold rolling-annealing preparation process, using one component to produce Process control, yield strength 400 ~ 650MPa, tensile ≥ 780MPa, elongation A 80 ≥18%, n 10-20 / Ag value ≥ 0.14, r 90 Value ≥ 0.8, BH 2 ≥50MPa performance index. Hot rolling process design: final rolling temperature: 850°C; coiling temperature: 550°C. Cold rolling, anneal...

Embodiment 2

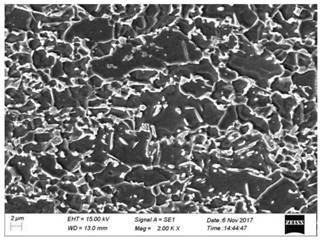

[0046] Manufacture of seat reinforcements by press forming

[0047] The production process of cold-rolled dual-phase steel DP780 is: pretreatment of molten steel → converter smelting → refining outside the furnace → continuous casting → hot rolling heating → rough rolling, finishing rolling → controlled cooling → coiling → cold rolling uncoiling, welding → acid Washing, cold rolling→continuous annealing→leveling→surface, performance inspection, composition by weight percentage, including C: 0.13, Si: 0.10, Mn: 1.0, Ti: 0.01, Cr: 0.10, Al: 0.02, P: ≤0.015 , S: ≤0.010, the rest are Fe and unavoidable impurities. Through the steelmaking-hot rolling-cold rolling-annealing preparation process, one component is used to control the production process, and the martensite volume fraction of cold-rolled dual-phase steel DP780 is about 16%, the average grain size is 3μm, and the yield strength 425MPa, tensile strength ≥ 815MPa, elongation A 80 ≥22.5%, n 10-20 / Ag value ≥ 0.16, r 90 Va...

Embodiment 3

[0049] The production process of cold-rolled dual-phase steel DP780 is: pretreatment of molten steel → converter smelting → refining outside the furnace → continuous casting → hot rolling heating → rough rolling, finishing rolling → controlled cooling → coiling → cold rolling uncoiling, welding → acid Washing, cold rolling→continuous annealing→leveling→surface, performance inspection, composition by weight percentage, including C: 0.13, Si: 0.10, Mn: 1.0, Ti: 0.01, Cr: 0.10, Al: 0.02, P: ≤0.015 , S: ≤0.010, the rest is Fe and unavoidable impurities; the martensite volume fraction of the cold-rolled dual-phase steel DP780 in this example is about 19%, the average grain size is 4μm, the yield strength is 613MPa, and the tensile strength is ≥835MPa , elongation A 80 ≥22%, n 10-20 / Ag value ≥ 0.16, r 90 Value ≥ 0.9, BH 2 ≥63. After punching→welding→longitudinal roll forming→spot welding→bending forming→shearing→cutting to length, the finished parts are finally made into finishe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com