Wind-power equipment casting and manufacturing method thereof

A technology for wind power equipment and castings, which is applied in the field of wind power equipment castings and their preparation, which can solve the problems of declining corporate profits, many harmful elements, and poor quality of pig iron, and achieve uniform distribution of graphite spheres, high ferrite content, and nodularization rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

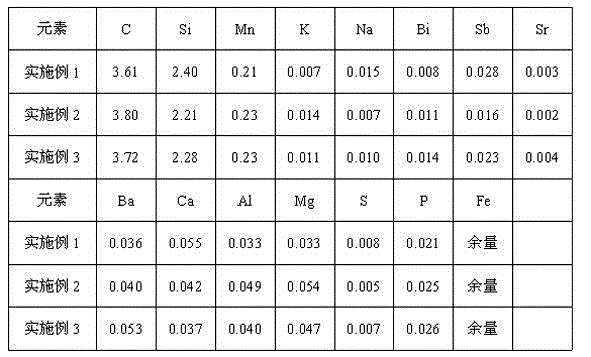

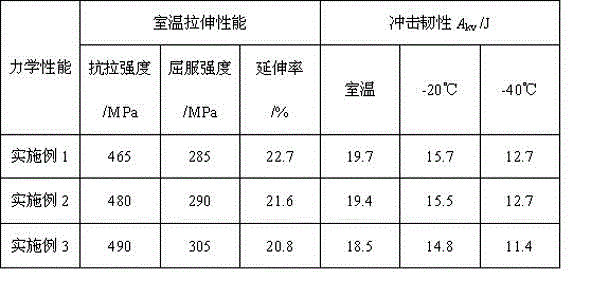

Embodiment 1

[0039] A 15-ton industrial frequency induction furnace is used to melt cast iron. The specific manufacturing process steps are:

[0040] Step 1: Heat and melt low-manganese steel scrap and graphite in an electric furnace. When the temperature of molten iron rises to 1478°C, add ferrosilicon for deoxidation and alloying at the same time, then add aluminum for final deoxidation. When the temperature of molten iron reaches 1517°C, add potassium Substances, sodium-containing substances and electrolytic bismuth are added into the furnace, and the molten iron is released after the composition is qualified;

[0041] The second step: molten iron spheroidization treatment, in the process of molten iron, metal antimony is washed into the ladle with the flow, and then the passivated magnesium particles are sprayed into the molten iron with a spray gun, and the amount of passivated magnesium particles accounts for 0.03% of the mass fraction of the molten iron , after standing still and re...

Embodiment 2

[0047] A 15-ton industrial frequency induction furnace is used to melt cast iron. The specific manufacturing process steps are:

[0048] Step 1: First heat and melt low-manganese steel scrap and graphite in an electric furnace. When the temperature of molten iron rises to 1463°C, add ferrosilicon for deoxidation and alloying at the same time, then add aluminum for final deoxidation. When the temperature of molten iron reaches 1504°C, add potassium Substances, sodium-containing substances and electrolytic bismuth are added into the furnace, and the molten iron is released after the composition is qualified;

[0049] The second step: molten iron spheroidization treatment, in the process of molten iron, the metal antimony is washed into the ladle with the flow, and then the passivated magnesium particles are sprayed into the molten iron with a spray gun, and the amount of passivated magnesium particles accounts for 0.02% of the mass fraction of the molten iron , after standing st...

Embodiment 3

[0055] A 15-ton industrial frequency induction furnace is used to melt cast iron. The specific manufacturing process steps are:

[0056] Step 1: Heat and melt low-manganese steel scrap and graphite in an electric furnace. When the temperature of molten iron rises to 1471°C, add ferrosilicon for deoxidation and alloying at the same time, then add aluminum for final deoxidation. When the temperature of molten iron reaches 1508°C, add potassium Substances, sodium-containing substances and electrolytic bismuth are added into the furnace, and the molten iron is released after the composition is qualified;

[0057] The second step: molten iron spheroidization treatment, in the process of molten iron, metal antimony is washed into the ladle with the flow, and then the passivated magnesium particles are sprayed into the molten iron with a spray gun, and the amount of passivated magnesium particles accounts for 0.025% of the mass fraction of the molten iron , after standing still and r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com