Acid-resisting, high-toughness and high-wear-resisting cast ball and preparing method thereof

A high anti-wear and cast ball technology, applied in the field of casting, can solve the problems that ordinary cast balls and ultra-high chromium balls cannot meet the requirements of working conditions, increase production costs, and consume large grinding balls, so as to achieve good economic benefits and eliminate stress , Improve the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

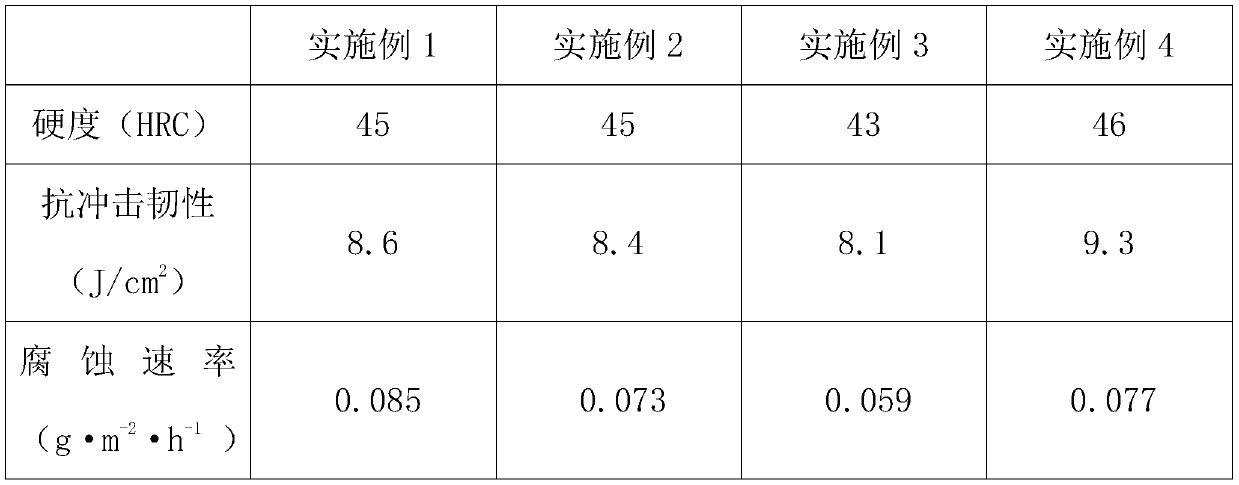

Examples

Embodiment 1

[0019] A method for preparing an acid-resistant tough high-wear casting ball, comprising the following steps:

[0020] S1. Add steel scrap, recarburizer, ferrochromium, ferromanganese, ferrosilicon, ferronickel, and ferromolybdenum in sequence in the smelting furnace, and smelt at 1520-1540°C to obtain molten iron;

[0021] S2. Add 0.3kg / t aluminum ingot to the molten iron for deoxidation before it is released from the furnace, then transfer the molten iron to the transfer ladle, remove the slag and pour it into the pouring ladle, pour it at 1450°C, and obtain the billet after cooling ;

[0022] S3. Raise the temperature of the billet to 500°C for 2 hours, then raise the temperature to 780°C for 2 hours, then raise the temperature to 940°C for 2 hours, then raise the temperature to 1015°C for 2 hours, quench with quenching oil for 10 minutes, and finally keep the temperature at 260°C for 6 hours Tempering treatment is carried out to obtain acid-resistant, strong, tough and we...

Embodiment 2

[0025] A method for preparing an acid-resistant tough high-wear casting ball, comprising the following steps:

[0026] S1. Add steel scrap, recarburizer, ferrochrome, ferromanganese, ferrosilicon, ferronickel, and ferromolybdenum in sequence in the smelting furnace, and smelt at 1530°C to obtain molten iron;

[0027] S2. Add 0.4kg / t aluminum ingot to the molten iron for deoxidation before it is released from the furnace, then transfer the molten iron to the transfer ladle, remove the slag and pour it into the pouring ladle, pour it at 1500°C, and obtain the billet after cooling ;

[0028] S3. Raise the temperature of the billet to 500°C for 2 hours, then raise the temperature to 780°C for 2 hours, then raise the temperature to 950°C for 3 hours, then raise the temperature to 1030°C for 3 hours, quench with quenching oil for 12 minutes, and finally keep the temperature at 275°C for 7 hours Tempering treatment is carried out to obtain acid-resistant, strong, tough and wear-resi...

Embodiment 3

[0031] A method for preparing an acid-resistant tough high-wear casting ball, comprising the following steps:

[0032] S1. Add steel scrap, recarburizer, ferrochrome, ferromanganese, ferrosilicon, ferronickel, and ferromolybdenum in sequence in the smelting furnace, and smelt at 1540°C to obtain molten iron;

[0033] S2. Add 0.5kg / t aluminum ingot to the molten iron for deoxidation before it is released from the furnace, then transfer the molten iron to the transfer ladle, remove the slag and pour it into the pouring ladle, pour it at 1520°C, and obtain the slab after cooling ;

[0034] S3. Raise the temperature of the billet to 510°C for 3 hours, then raise the temperature to 790°C for 3 hours, then raise the temperature to 950°C for 3 hours, then raise the temperature to 1030°C for 3 hours, quench with quenching oil for 15 minutes, and finally keep the temperature at 280°C for 8 hours Tempering treatment is carried out to obtain acid-resistant, strong, tough and wear-resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com