Preparation technology of wear-resistant and high-hardness wear-resistant plate and scraper conveyor comprising wear-resistant plates

A scraper conveyor and preparation technology, applied in the field of machinery, can solve problems such as scraper wear, increase production and maintenance costs, breakage, etc., achieve good casting performance, promote and stabilize pearlite production, and increase strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

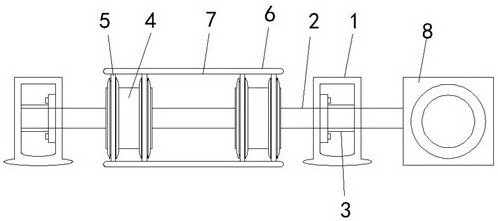

[0028] Such as figure 1 As shown, the scraper conveyor based on the wear-resistant plate according to the embodiment of the present invention includes two frames 1, a drive shaft 2 is arranged between the two frames 1, and a The bearing housing 3 matched with the drive shaft 2, the middle part of the outer surface of the drive shaft 2 is provided with a sprocket 4 located in the two frames 1, and a chain 5 is provided on the sprocket 4 , the chain 5 is provided with several scrapers 6, and the scraper 6 is provided with a wear-resistant plate 7, and one end of the drive shaft 2 runs through the frame 1 and is connected to the output end of the drive motor 8;

[0029] The frame 1 is provided with a number of supporting rollers matched with the drive shaft 2, and each end of the supporting roller is provided with a sprocket 4, and the chain 5 is wound around several of the sprockets. 4; the wear-resistant plate 7 is clamped and fixed with the scraper 6, the scraper 6 is provide...

Embodiment 2

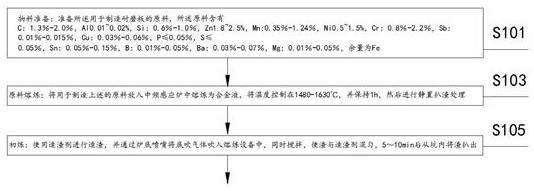

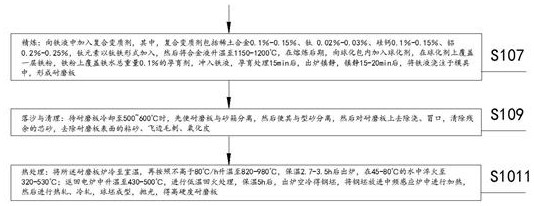

[0031] Such as Figure 1-3 As shown, according to an embodiment of the present invention, a process for preparing a wear-resistant and high-hardness wear-resistant plate for a scraper conveyor based on a wear-resistant plate is provided, including the following steps:

[0032] Step S101, preparing the raw material for manufacturing the wear-resistant plate, the raw material contains C: 1.3%-2.0%, Al0.01-0.02%, Si: 0.6%-1.0%, Zn1.8-2.5%, Mn :0.35%-1.24%, Ni0.5~1.5%, Cr: 0.8%-2.2%, Sb: 0.01%-0.015%, Cu: 0.03%-0.06%, P≤0.05%, S≤0.05%, Sn: 0.05%-0.15%, B: 0.01%-0.05%, Ba: 0.03%-0.07%, Mg: 0.01%-0.05%, the balance is Fe;

[0033] Step S103, putting the above-mentioned raw materials into a medium-frequency induction furnace to melt into an alloy liquid, controlling the temperature at 1480-1630° C., and keeping it for 1 hour, and then performing static slag removal treatment;

[0034] Step S105, using a slagging agent to make slagging, and blowing the bottom blowing gas into the sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com