Novel as-cast 500-7 nodular cast iron

A ductile iron and as-cast technology, applied in the field of new as-cast 500-7 ductile iron, can solve the problems of affecting the production efficiency of iron mold sand coating, unfavorable mass production, low ferrite content, etc. Superior performance and the effect of increasing Si content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

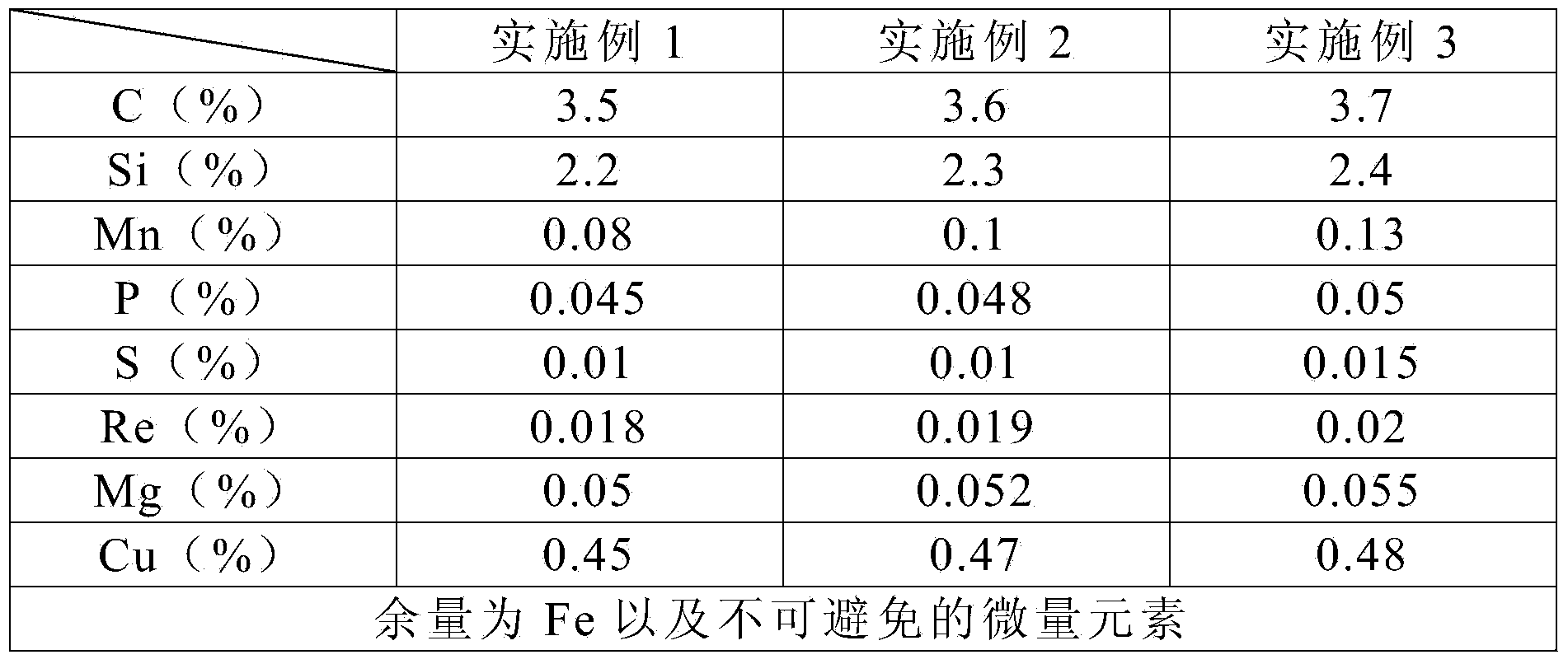

Embodiment 1-3

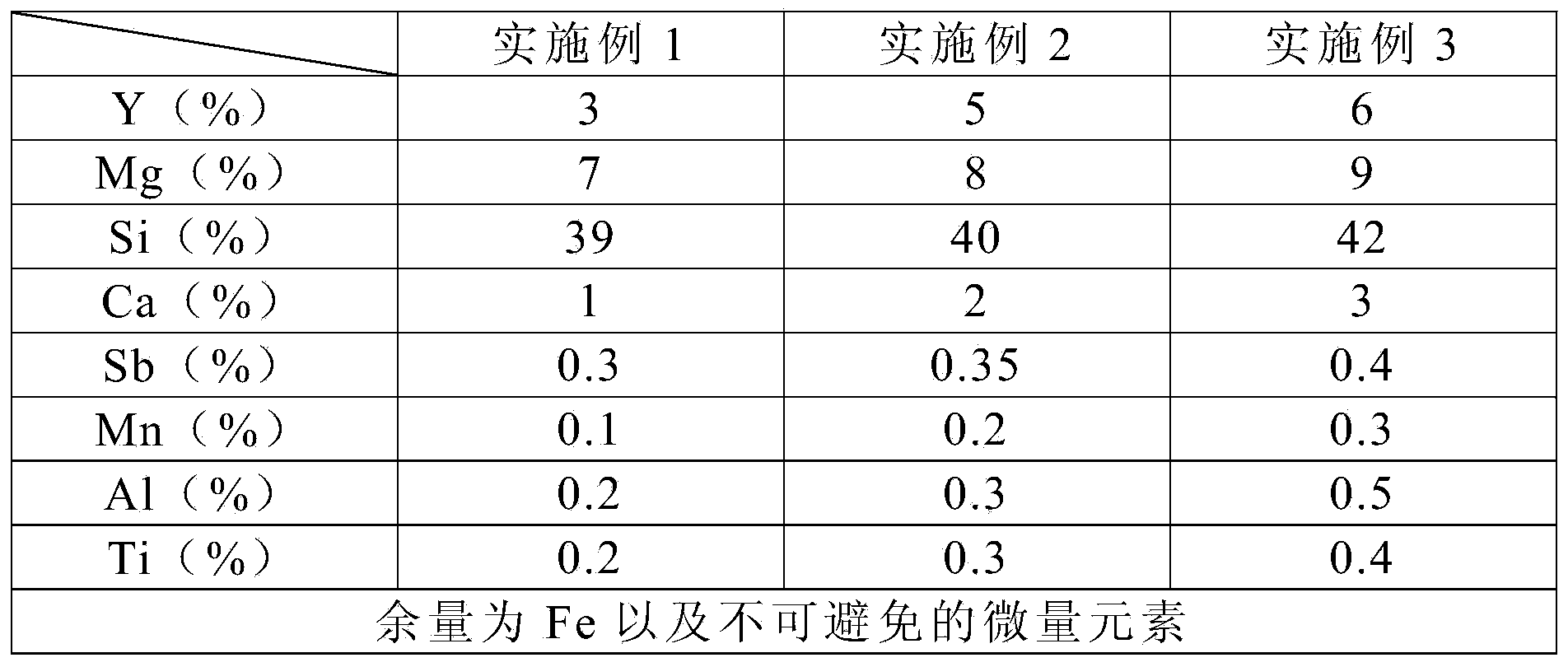

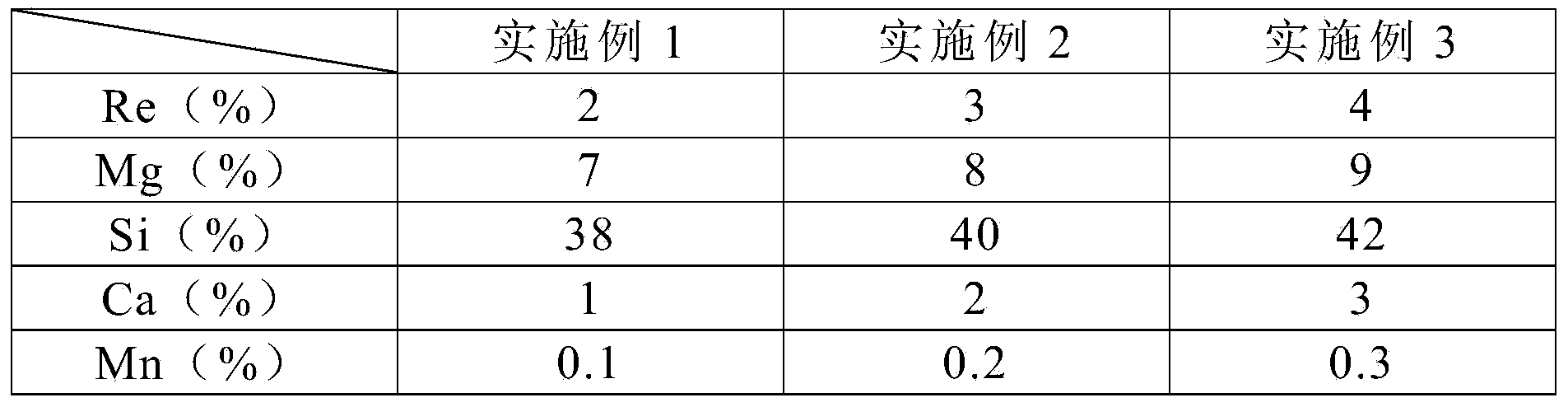

[0039] Table 4 Example 1-3 Inoculant mass percentage

[0040]

Embodiment 1

[0042] Weigh the coke, limestone, scrap, new iron, reheated iron and ferroalloy according to the mass percentage of the new as-cast 500-7 ductile iron in Example 1 of Table 1, and put them into the cupola in order. After preheating for 20 minutes, the molten iron temperature is Smelt at 1430℃. After smelting, detect the content of each element in the molten iron and adjust the content of each element until it meets the mass percentage of the new as-cast 500-7 ductile iron.

[0043] When the amount of molten iron in the molten iron ladle reaches the required level, add the first nodulizing agent and the second nodulating agent in Table 2 and Table 3 in Example 1 with a total mass of 1.7% of the mass of the molten iron on the side of the nodulizing ladle. The first spheroidizing agent accounts for 40% of the mass of all spheroidizing agents, the second spheroidizing agent accounts for 60% of the mass of all spheroidizing agents, the first spheroidizing agent is on the bottom, the se...

Embodiment 2

[0047] Weigh the coke, limestone, scrap, new iron, recycled iron, and ferroalloy according to the mass percentage of the new as-cast 500-7 ductile iron in Table 1 and Example 2, and put them into the cupola in order. After preheating for 25 minutes, the molten iron temperature is It is smelted at 1440°C. After smelting, the content of each element in the molten iron is detected and the content of each element is adjusted until it meets the mass percentage of the new as-cast 500-7 ductile iron.

[0048] When the amount of molten iron in the molten iron ladle reaches the required level, add the first nodulizing agent and the second nodulizing agent in Table 2 and Table 3 in Example 2 with a total mass of 1.75% of the mass of the molten iron on the side of the nodulizing ladle, wherein The first spheroidizing agent accounts for 40% of the mass of all spheroidizing agents, the second spheroidizing agent accounts for 60% of the mass of all spheroidizing agents, the first spheroidizing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com