Nodular cast iron inoculant and preparation method thereof and application in smelting nodular cast iron

A technology of nodular cast iron and inoculant, which is applied in the application of smelting nodular cast iron, the field of nodular cast iron inoculant and its preparation, can solve the problems of backlog of returned material, waste in industrial production, coarse graphite nodules, etc., so as to improve impact resistance, The effect of improving economic efficiency and reducing the tendency of white mouth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

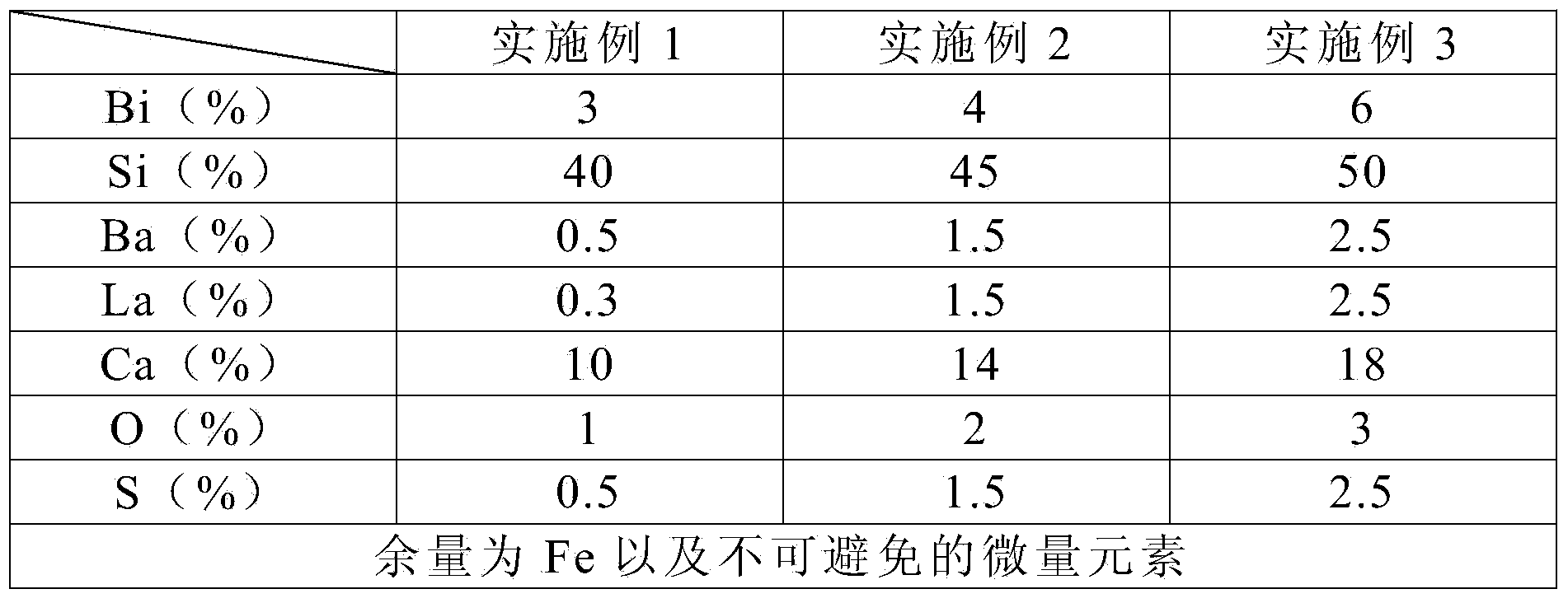

[0037] Table 1 embodiment 1-3 ductile iron inoculant mass percentage

[0038]

[0039] Example 1:

[0040] Take by weighing FeS, CaSi, Bi 2 o 3 , La 2 o 3 , BaO, and FeS, CaSi, Bi 2 o 3 , La 2 o 3 , BaO mixed with ferrosilicon-based alloy, adding binder sodium silicate, pressing the mixture in a rolling device to make FeS, CaSi, Bi 2 o 3 , La 2 o 3 , BaO and ferrosilicon-based alloy are mixed into agglomerates, and then the agglomerates are broken, sieved and wrapped with aluminum foil to inoculants of different sizes.

Embodiment 2

[0042] Fe is taken by weighing the nodular cast iron inoculant mass percent in the embodiment 2 of table 1 2 o 3 , CaSi, Bi 2 o 3 , La 2 o 3 、BaO 2 , and through the mechanical Fe 2 o 3 , CaSi, Bi 2 o 3 , La 2 o 3 、BaO 2 Mix with ferrosilicon-based alloy, add potassium silicate as a binder, and press the mixture in a rolling device to make Fe 2 o 3 , CaSi, Bi 2 o 3 , La 2 o 3 、BaO 2 Mix with ferrosilicon-based alloy to form a mass, then break the mass, sieve and wrap inoculants of different sizes with aluminum foil.

Embodiment 3

[0044] Take by weighing FeO, CaSi, Bi 2 o 3 , La 2 o 3 , BaO, and FeO, CaSi, Bi 2 o 3 , La 2 o 3 , BaO mixed with ferrosilicon-based alloy, adding binder calcium silicate, pressing the mixture in a rolling device to make FeO, CaSi, Bi 2 o 3 , La 2 o 3 , BaO and ferrosilicon-based alloy are mixed into agglomerates, and then the agglomerates are broken, sieved and wrapped with aluminum foil to inoculants of different sizes.

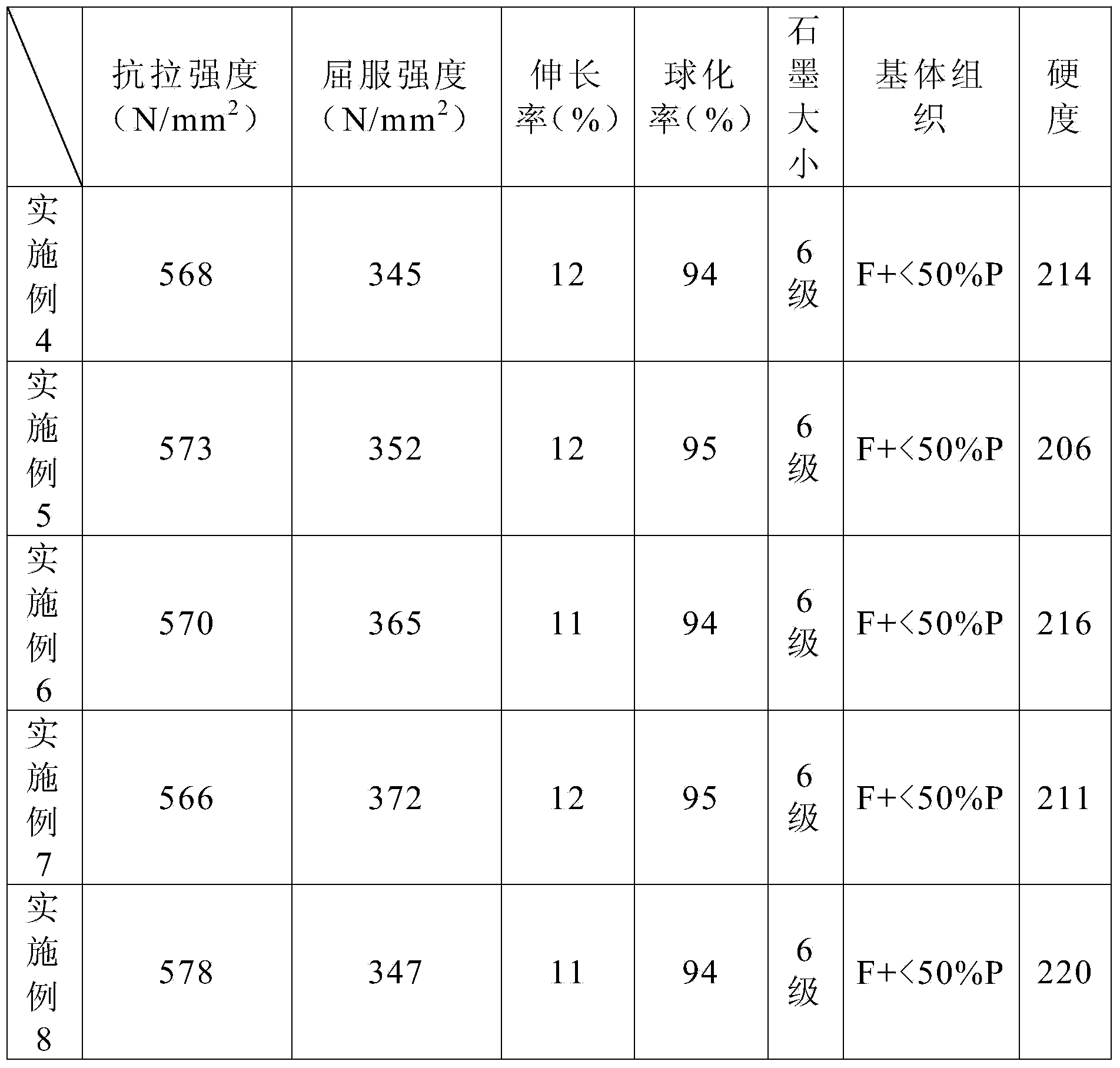

[0045] The nodular cast iron inoculants of the formulas of Examples 1-3 were prepared by the above method and used for the QT500-7 nodular cast iron, and the mechanical properties of the QT500-7 nodular cast iron were tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com